Semiconductor device

A semiconductor and metal film technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve problems such as the impact of semiconductor device reliability, and achieve the effect of small parasitic resistance and suppression of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

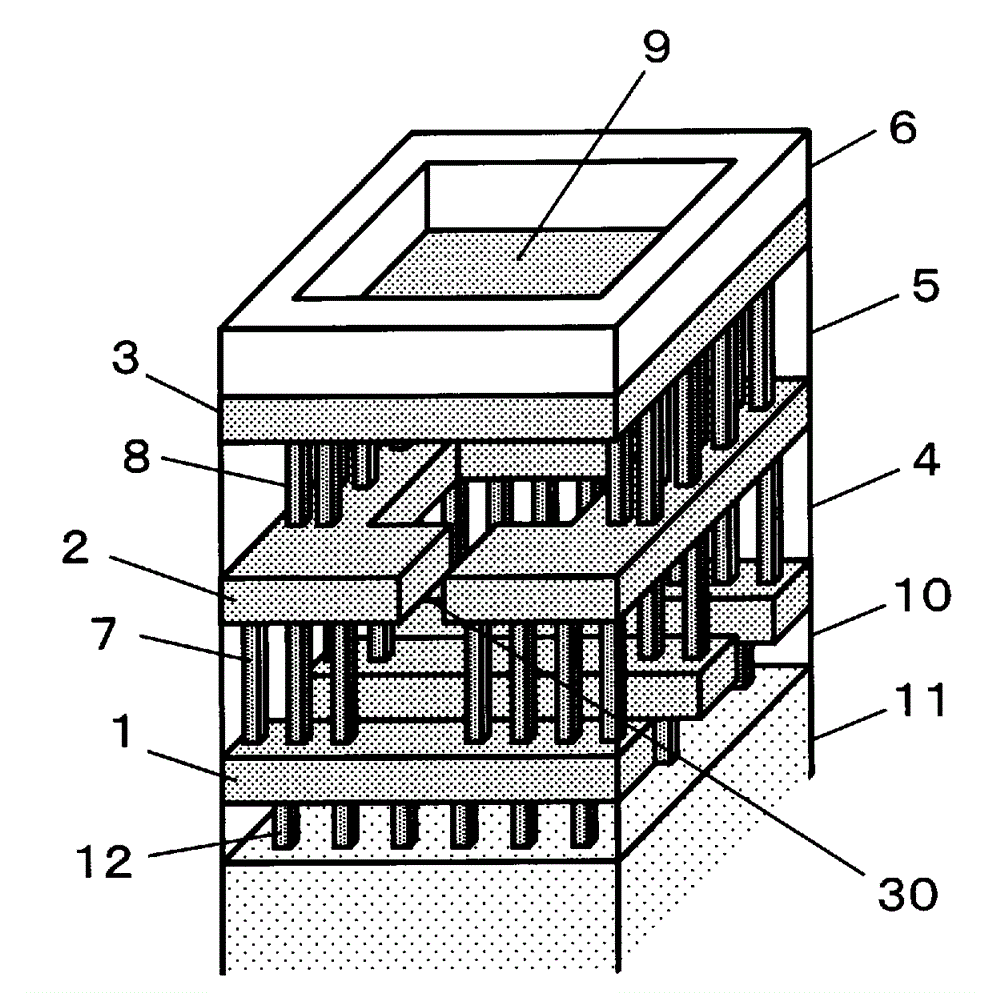

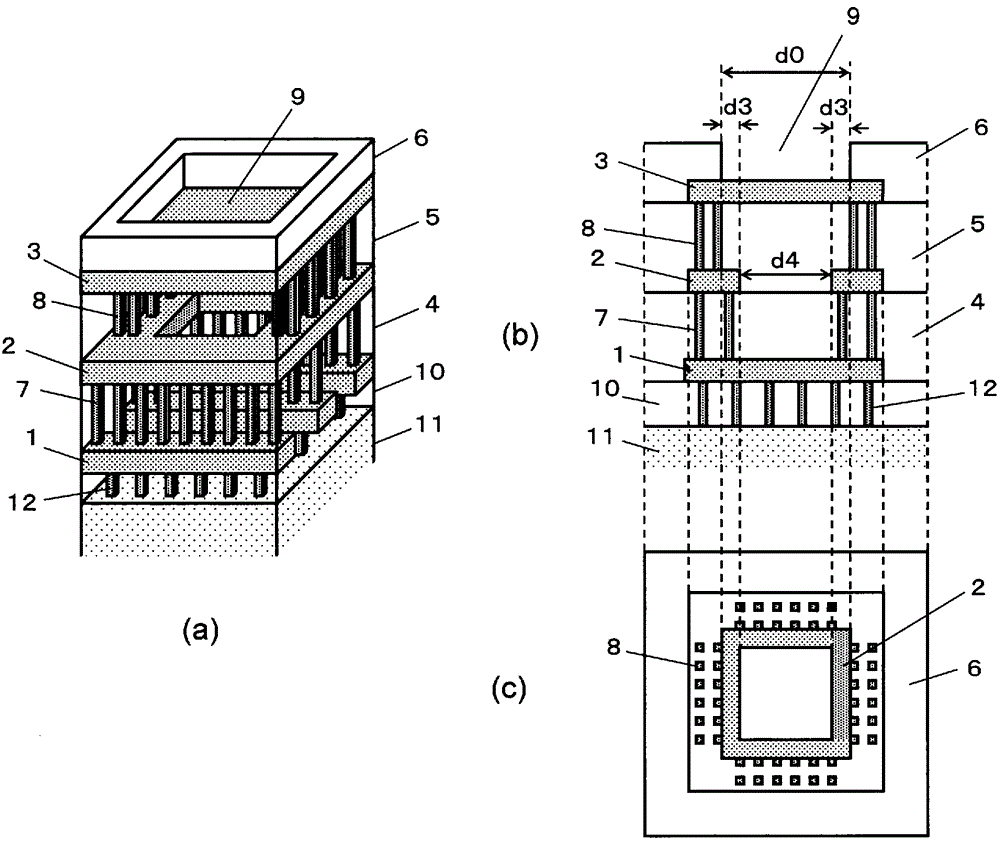

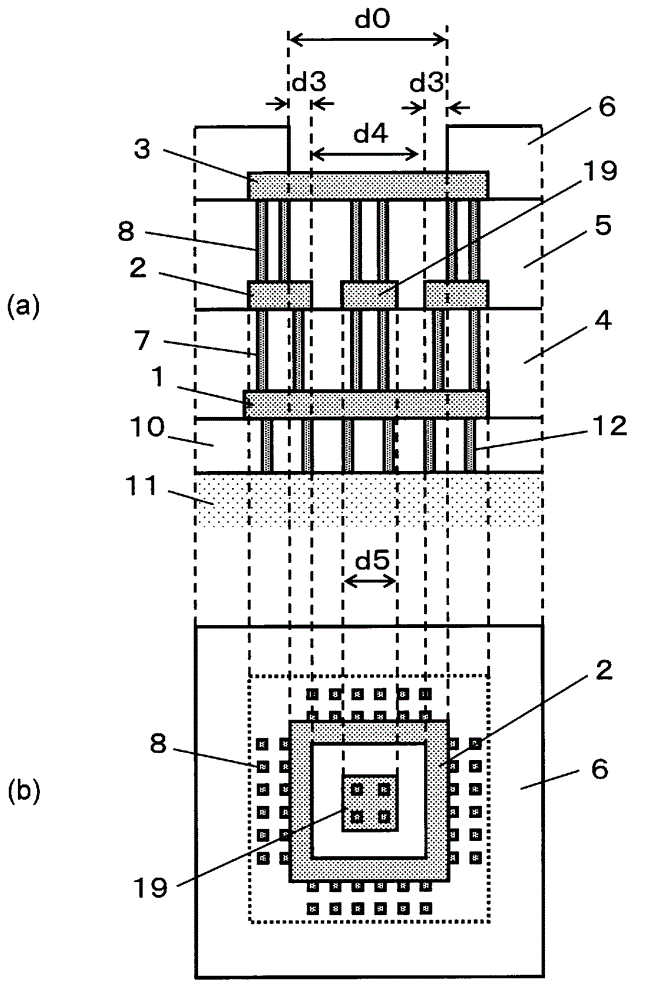

[0035] First, use figure 1 The pad structure of the semiconductor device of the present invention will be described. figure 1 (a) is a perspective view, (b) is a cross-sectional view, (c) is a plan view for explaining the relationship between the second metal film and the pad opening, and the uppermost metal film 3 is not shown.

[0036] Although not shown, elements are provided on the semiconductor substrate 11 . A first insulating film 10 is provided on a semiconductor substrate 11 , and a first metal film 1 is provided on the first insulating film 10 . The element and the first metal film 1 are electrically connected through the contact portion 12 . The second insulating film 4 is provided on the first metal film 1 , and the second metal film 2 is provided on the second insulating film 4 . The first metal film 1 and the second metal film 2 are electrically conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com