Transportable moisture limit test sample solid-liquid mixer

A technology of transportable moisture limit and solid-liquid mixer, applied in the preparation of test samples, etc., can solve the problems of waterway transportation risks, deviation of test results, etc., and achieve the effect of simple layout, stable operation, and full mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

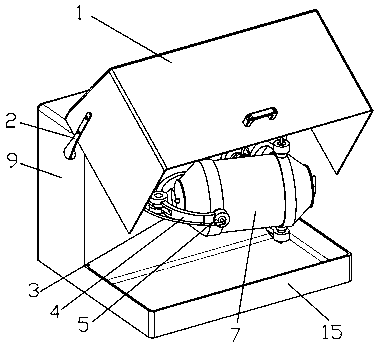

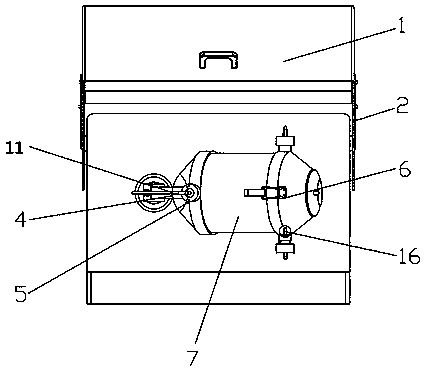

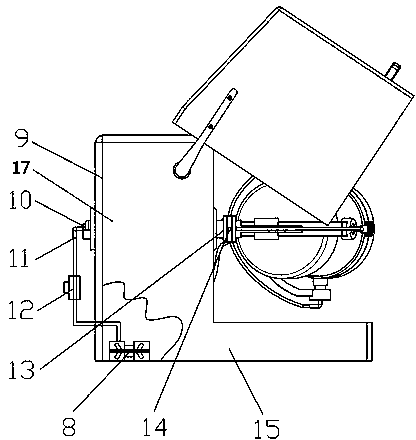

[0027] As shown in the figure, the sample solid-liquid mixer for the transportable moisture limit test of the present embodiment includes a base 15, the base 15 is connected to the box support 9, and the box support 9 is provided with a driving device 17 and a moisture adding device. The driving device 17 drives the mixing tank 7 to rotate through the transmission mechanism, and the water adding device communicates with the inner cavity of the mixing tank 7 through the liquid pipe 11 . The driving device 17 is set to a worm gear reducer motor, and the transmission mechanism is set to a linked rotation through shaft 10 and a universal joint. The rear end universal joint 13; the turbine shaft of the worm gear reducer motor is linked with the rotation through shaft 10, and the rotation through shaft 10 is connected to the front end universal joint 5 and the rear end universal joint 13 through the U-shaped arm 4, and is simultaneously linked to drive The mixing barrel 7 rotates; w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com