An Explosion-Driven Rapid Opening Valve

A valve, fast technology, applied in the direction of safety valve, balance valve, valve device, etc., can solve the problem of long opening time, and achieve the effect of ensuring safety and enhancing effective sealing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

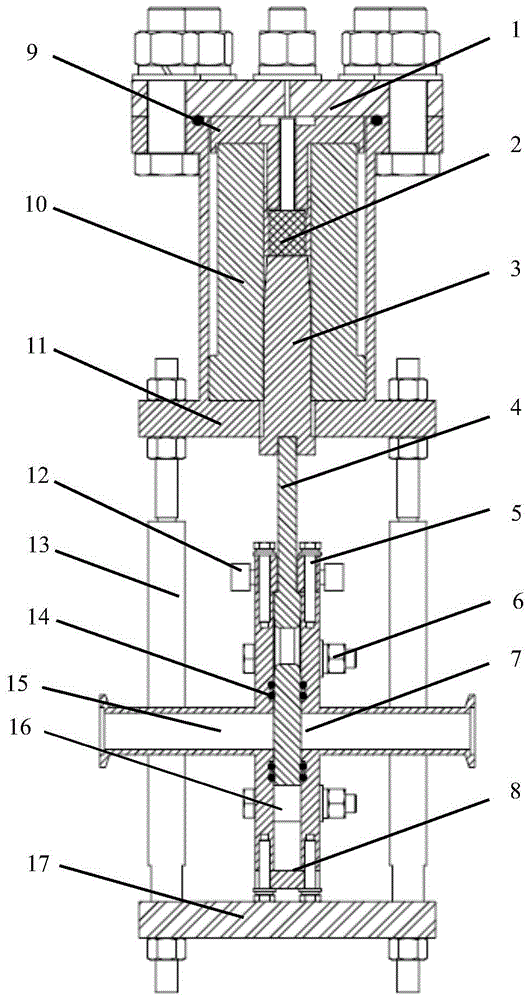

[0031] Such as figure 1 , figure 2 The schematic diagram of the main structure and working principle of the explosion-driven quick-opening valve is shown.

[0032] Including the main structural unit of the valve, the positioning unit and the explosion driving unit;

[0033] The main structural unit of the valve includes gate plate 4, two left and right limit baffles 5, multiple bolts 6, outer pipe flange 7, inner pipe flange 15, valve base 8, anti-rebound device 12 and two front and rear limit plates. pad 16;

[0034] The two limit baffles 5 on the left and right are respectively fixed on the upper ends of the outer pipeline flange 7 and the inner pipeline flange 15 and protrude inward to form a step; the gate plate 4 is located between the outer pipeline flange 7 and the inner pipeline flange 15, and It is located in the channel formed by the left and right limit baffles 5 and the front and rear two limit pads 16, and can only move up and down; the inner surface of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com