Valve and cooling system of friction clutch for wet running

A friction clutch and cooling system technology, which is applied in the field of friction clutch valves and cooling systems for wet operation, can solve the problem of high drag torque and achieve the effect of small drag torque and high cooling power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

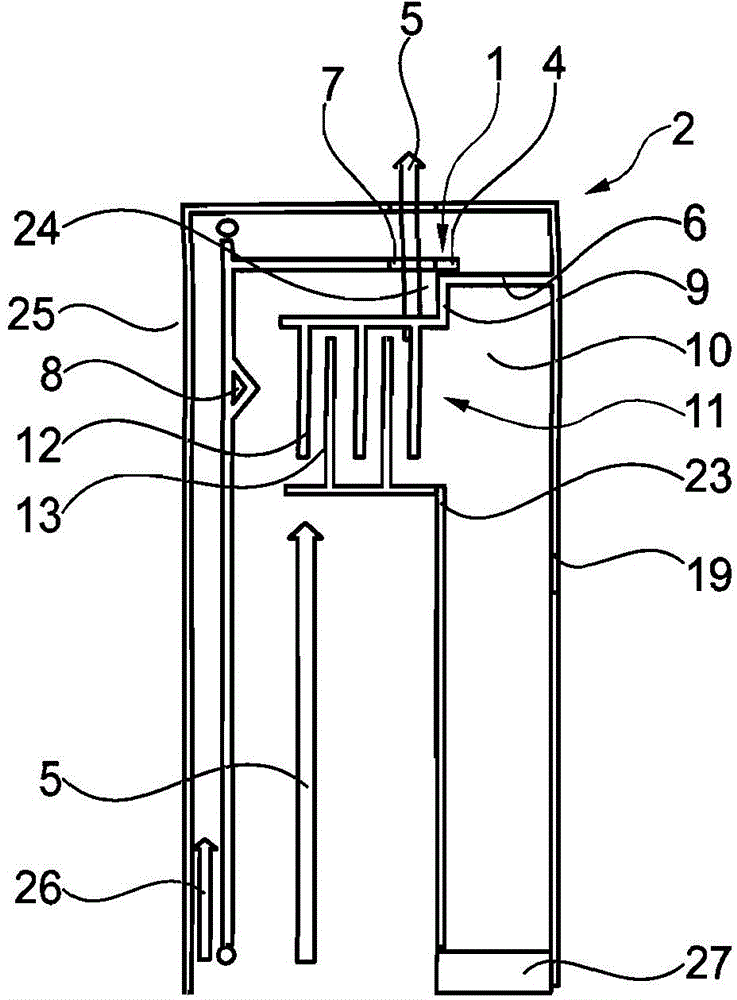

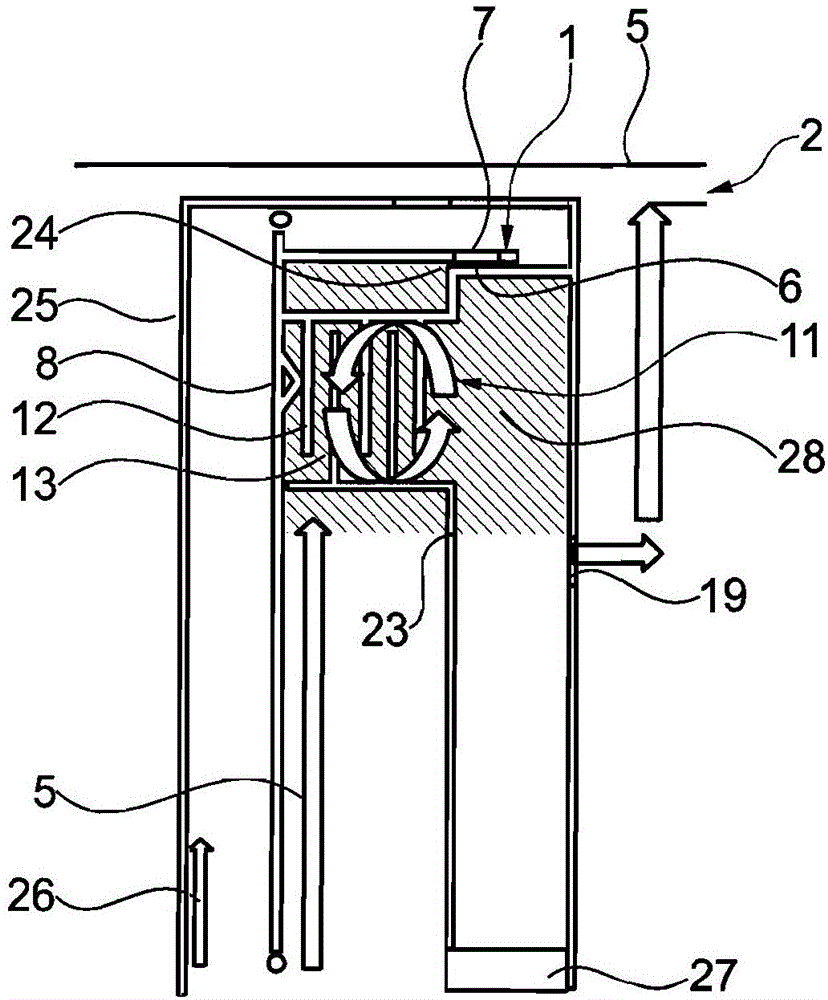

[0038] figure 1 A cooling system 2 is shown in which a valve 1 is provided, which is composed of an actuating piston 8 with a first outlet 7 and a blocking element 6 as a section of an outer disk cage 9 . A gap seal 24 is arranged between the actuating piston 8 and the blocking element 9 , which only allows a small portion of the cooling fluid 5 to flow through. Arranged in the outer disk cage 9 is a first friction partner 12 which corresponds to the second friction partner 13 in the inner disk cage 23 and forms the disk package 11 . The disc pack 11 can be closed by operating the piston 8, as follows in figure 2 shown in the . Furthermore, there is a second outlet 19 for the cooling fluid 5 , which is arranged below the disk pack 11 and above the output shaft 27 . In the first state shown here, almost no flow flows through the second outlet 19 . The actuating piston 8 is actuated by an actuating fluid 26 , which moves the actuating piston 8 in the direction of the disk p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com