General machine engine cooling structure

An engine cooling and general machine technology, applied in the direction of engine cooling, machine/engine, engine components, etc., can solve the problem that the forced air cooling structure is not interchangeable, so as to meet the requirements of forced air cooling heat dissipation, reduce heat load, Improve the effect of the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

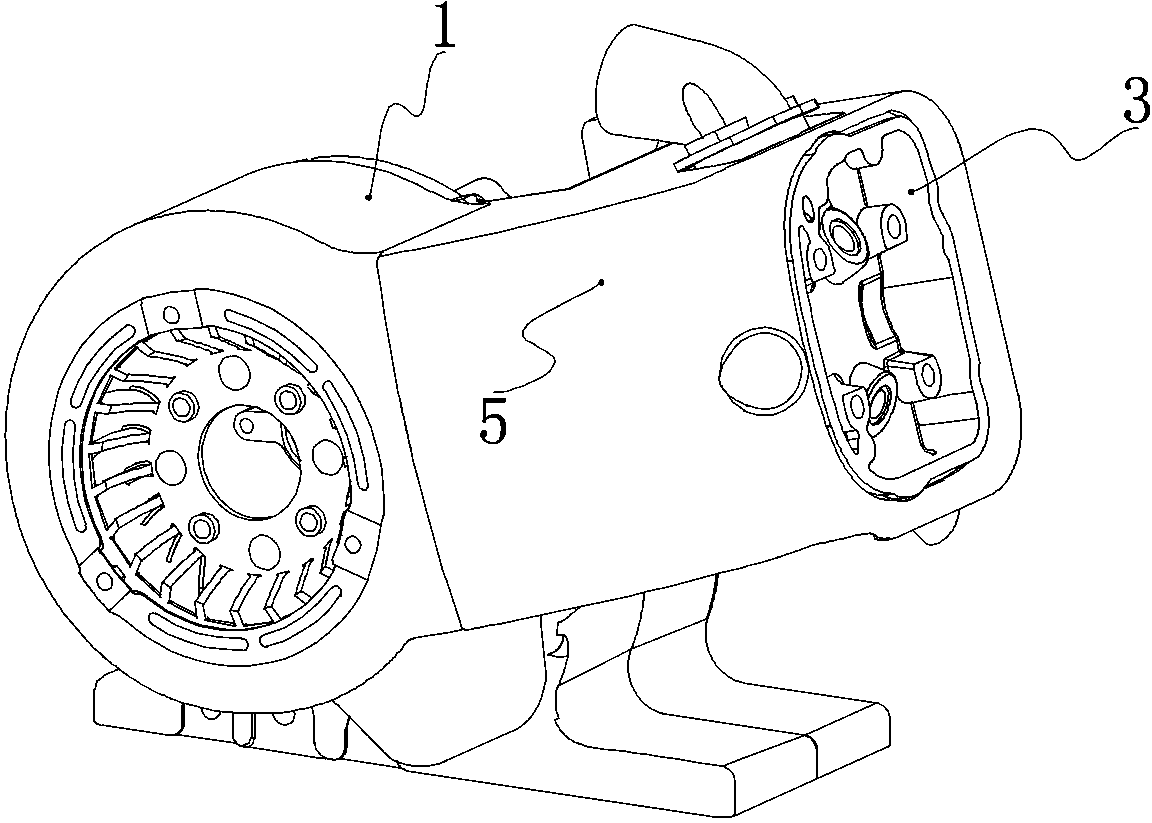

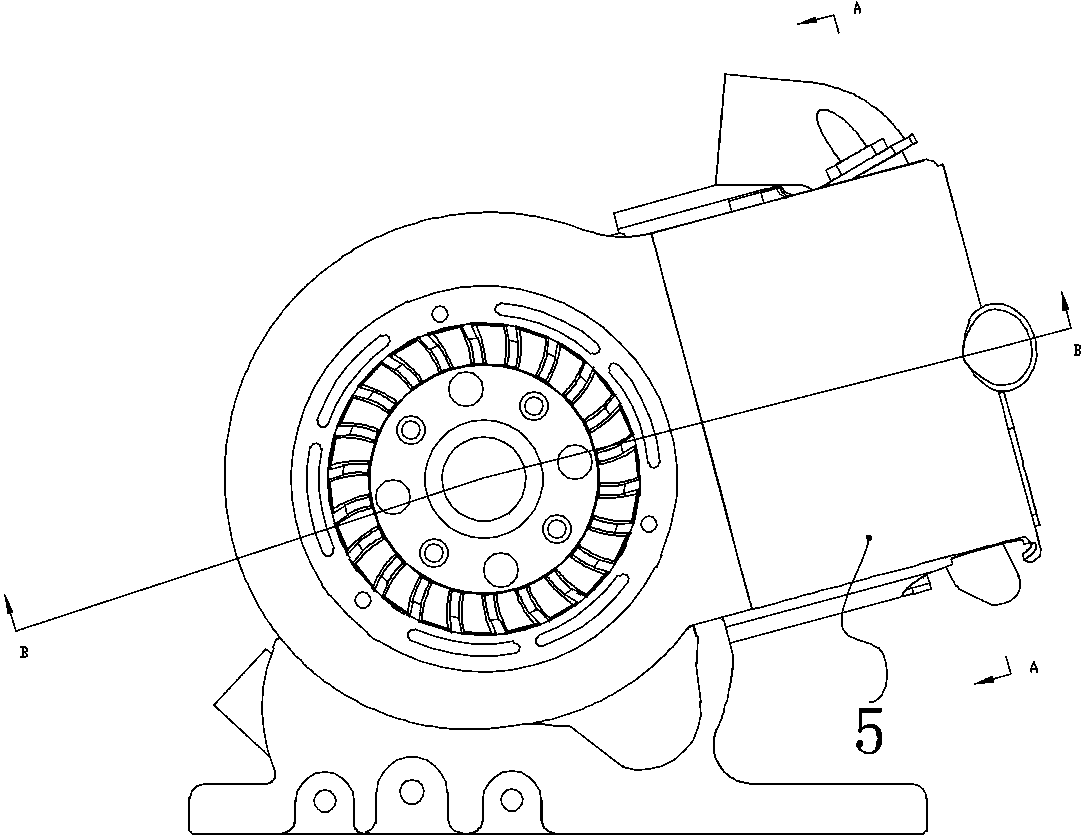

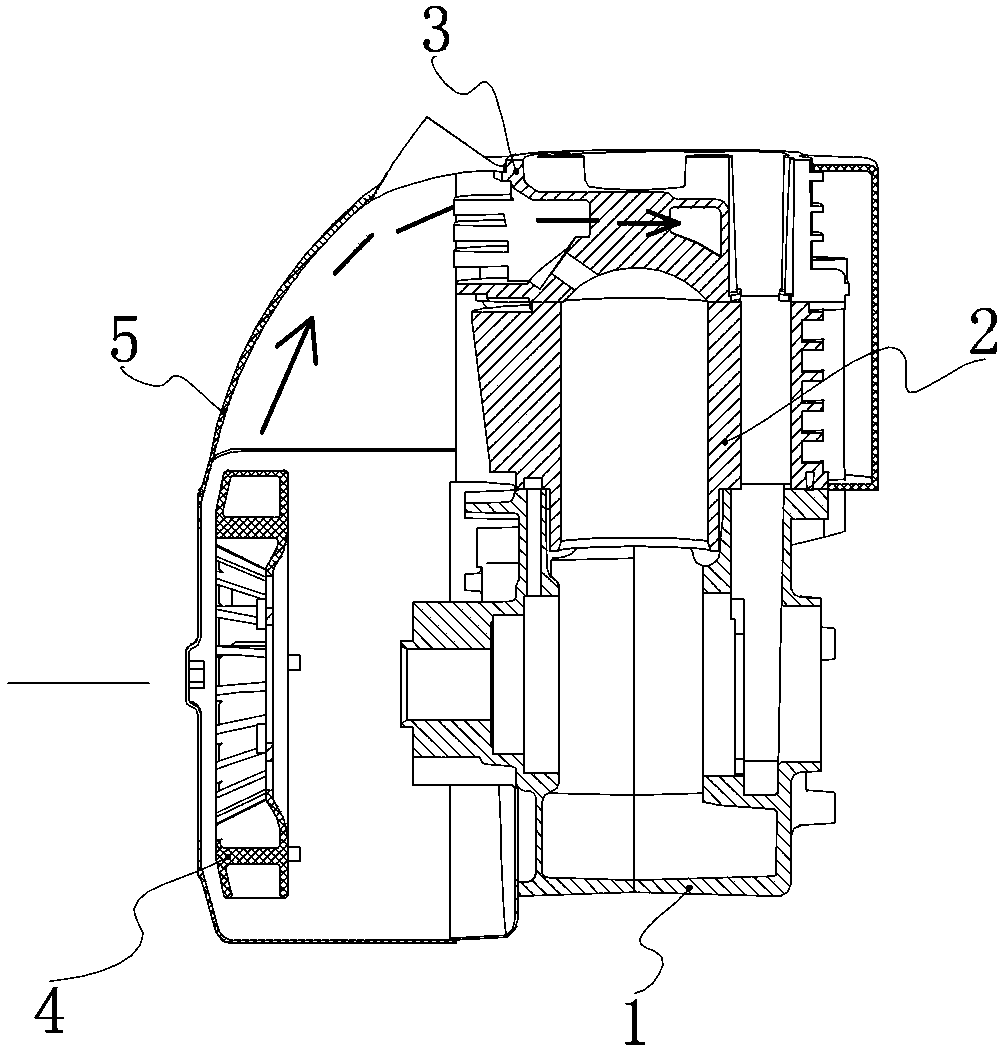

[0016] Such as figure 1 , figure 2 and image 3 As shown, in the general machine engine of the present invention, the crankcase 1 is located at the bottom of the whole engine, and the top of the crankcase 1 is provided with a cylinder block 2 and a cylinder head 3 in sequence. The magneto is located in the crankcase 1, the axle sleeve on the rotor of the magneto protrudes from the crankcase 1, and the cooling fan 4 is installed on the axle sleeve through the fan holder. The air guide cover 5 covers the cooling fan 4, the cylinder body 2 and the cylinder head 3, and the cooling air flow channel blowing from the cooling fan 4 to the cylinder head 3 is formed in the air guide cover 5, and the cooling air flow channel is at the cylinder head 3. Distributed to form three cooling air ducts. Such as Figure 4 As shown, the three cooling air passages in the figure are indicated by A, B, and C respectively, and the flow direction of the cooling air in the figure is indicated by ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com