All-fiber coal mine safety monitoring system

A technology of coal mine safety and monitoring system, applied in mining equipment, mining equipment, earthwork drilling and other directions, can solve the problems of non-explosion-proof detection equipment and low degree of automation, reduce potential risk factors, increase measurement function, precision and accuracy high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

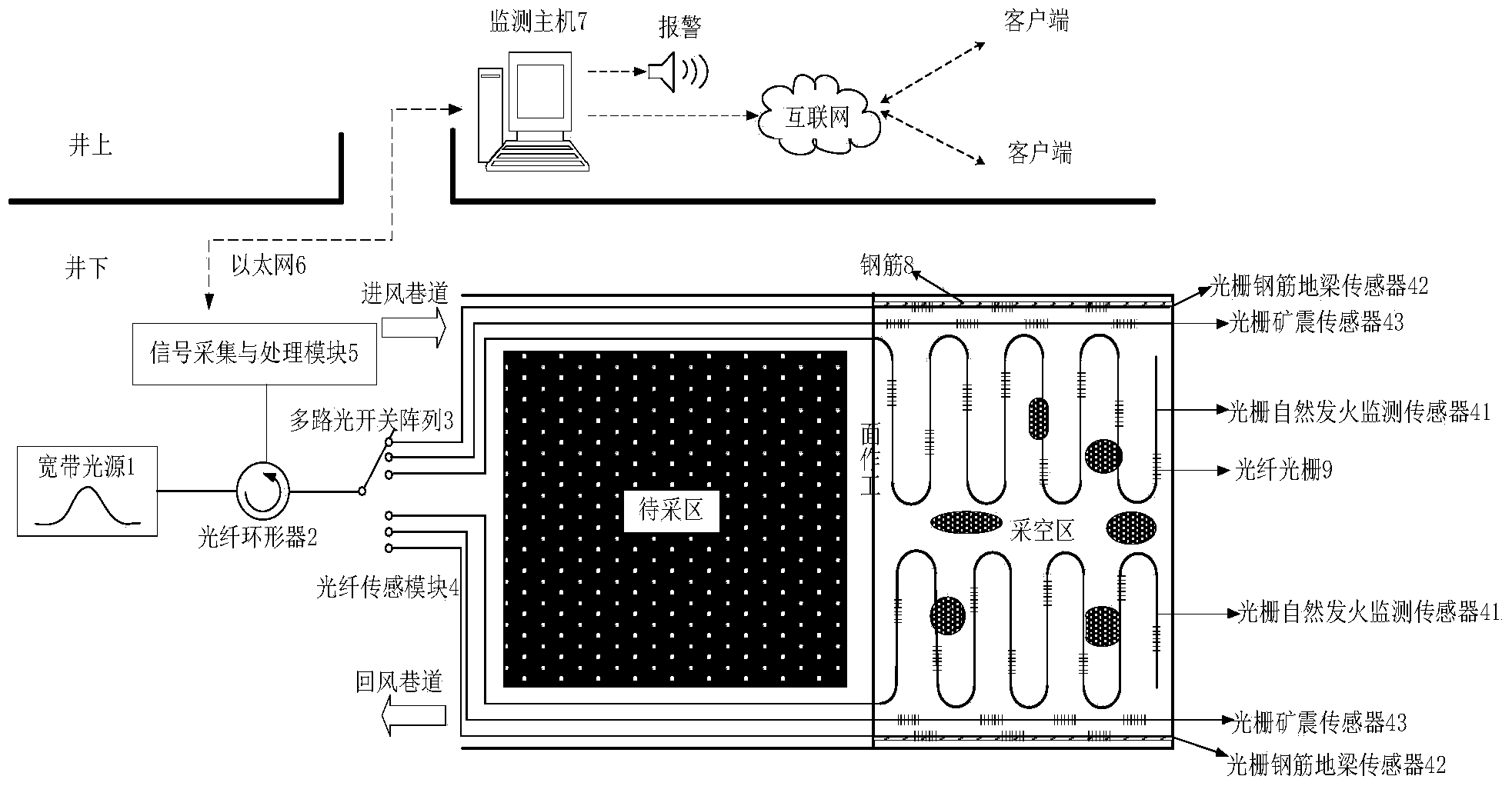

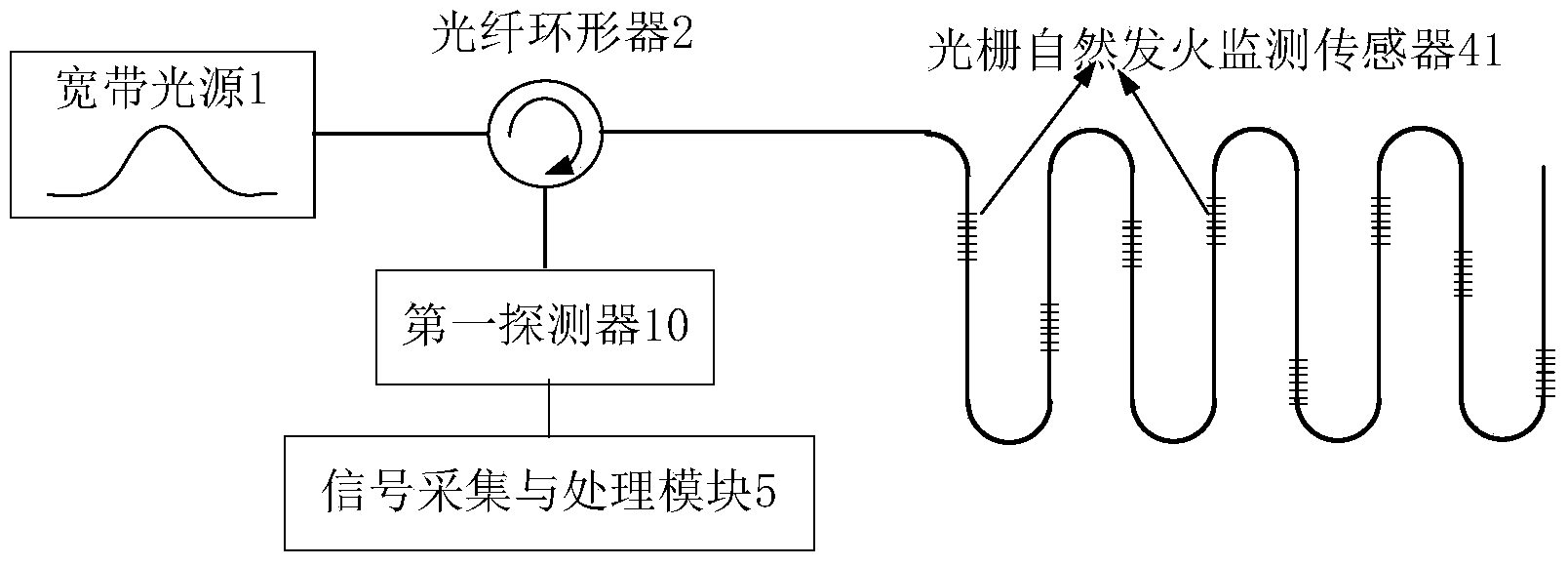

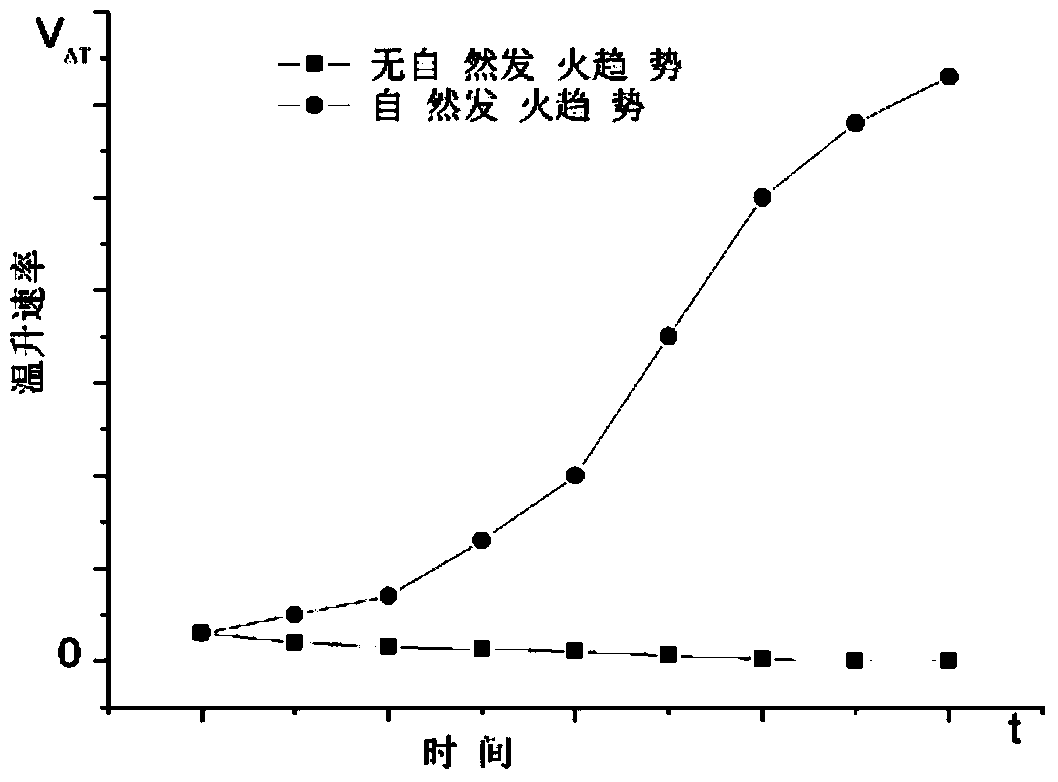

[0028] Such as figure 1 As shown, the system of the present invention is located underground, including a broadband light source 1, an optical fiber circulator 2, a multi-channel optical switch array 3, an optical fiber sensing module 4, and a signal acquisition and processing module 5; the optical fiber sensing module 4 includes a grating spontaneous ignition monitoring sensor 41. Grating reinforced ground beam sensor 42, grating mine earthquake sensor 43; grating spontaneous combustion monitoring sensor 41 monitors the temperature change rate of the coal seam in the goaf in real time, and timely forecasts coal mine spontaneous combustion; the grating reinforced ground beam sensor 42 detects the strain of the goaf To monitor the stratum health status in the coal mining area; the grating mine vibration sensor 43 realizes the monitoring of the stratum vibration in the coal mining area by detecting the micro-vibration of the stratum in the goaf; The switch array 3 is distributed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com