Method for constructing segmental prefabricating and assembling swing foundation pier

A technology of prefabricated assembly and bridge piers, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of long construction period, adverse impact on urban environment, and high construction conditions, and achieve short construction period, good seismic isolation effect, and construction effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

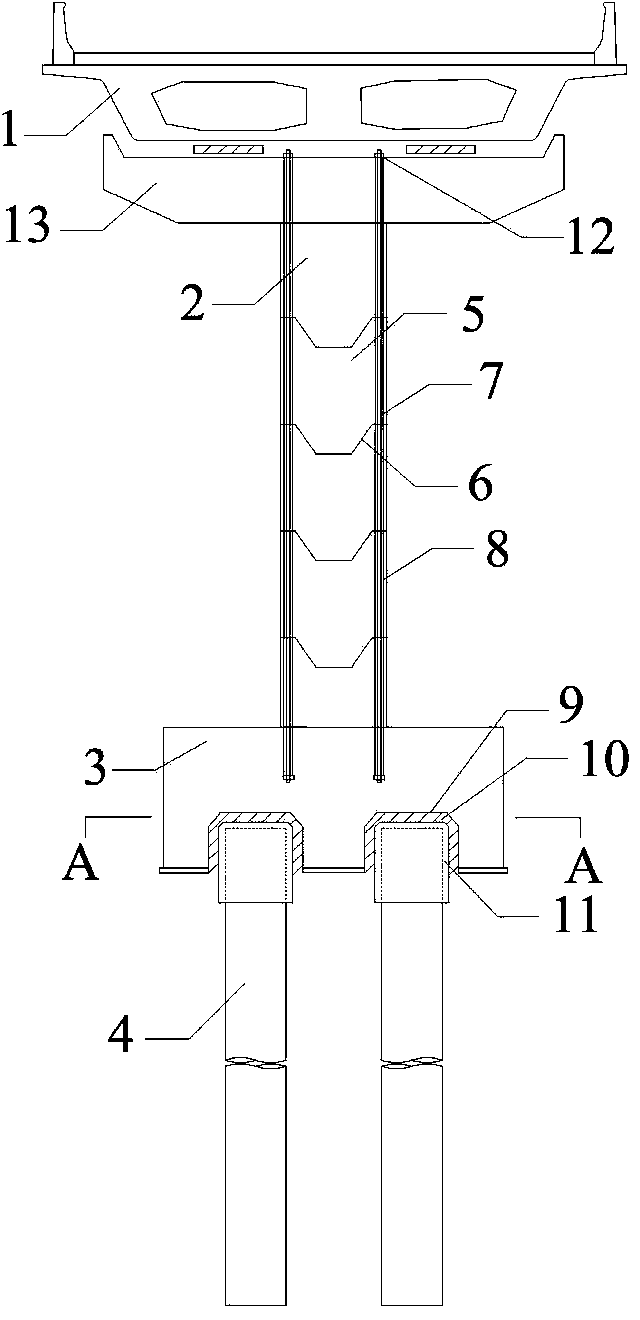

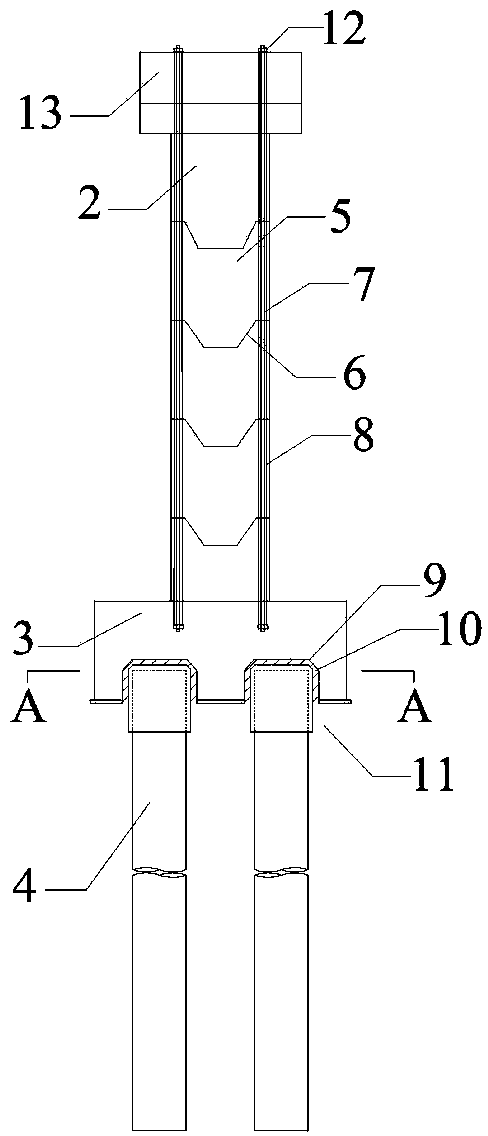

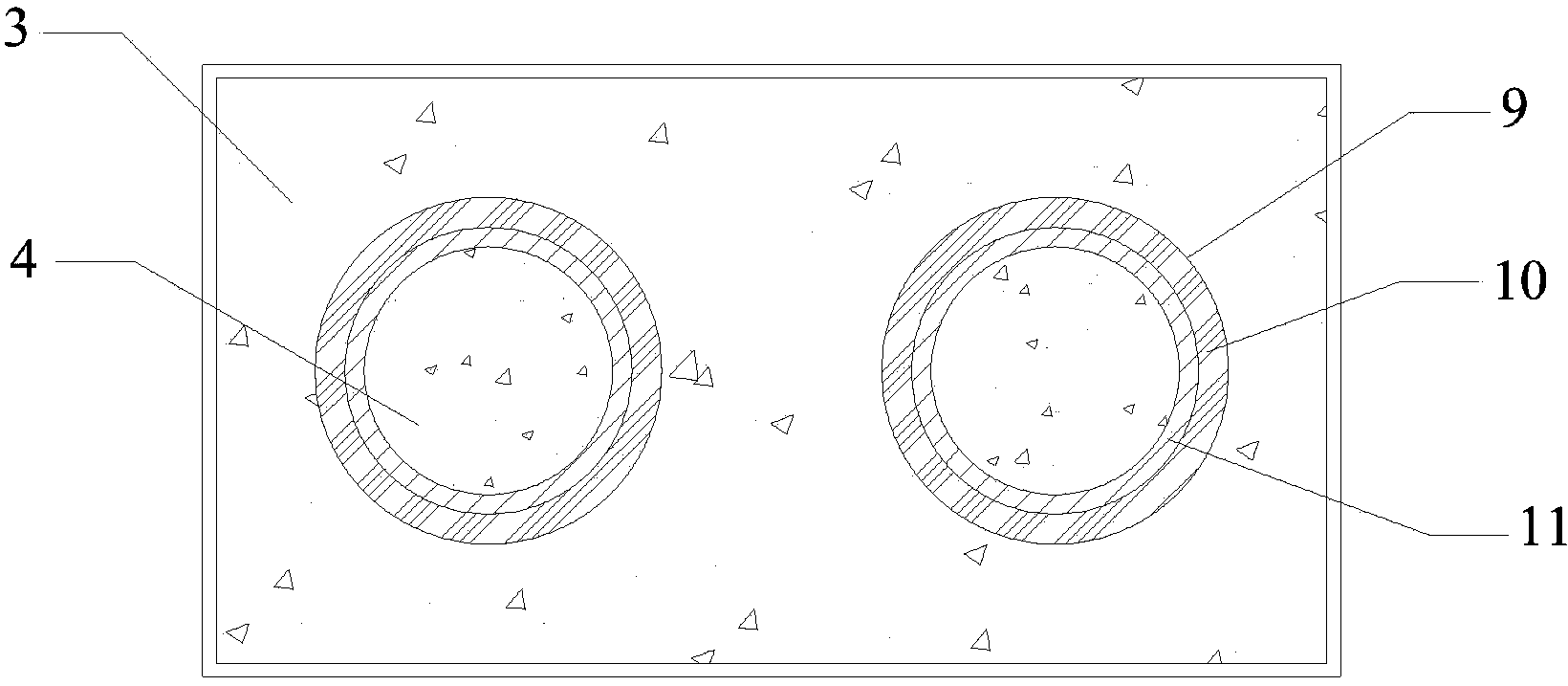

[0024] Such as Figure 1-6 As shown, under the action of natural disasters such as earthquakes, the seismic energy is counteracted by swaying to achieve the common purpose of "elimination" and "isolation" of the structural structure. The cap and pile foundation are no longer cast-in-place consolidation. , but a rockable splice. When the cap is prefabricated, the insertion aperture 9 of the pile foundation is reserved at the bottom. The diameter of the hole at the bottom of the cap is about 20cm larger than the diameter of the pile foundation. The pile top elevation is about 1.5 times the pile diameter higher than the bottom surface of the pile cap, and the pile top steel casing 11 is wrapped within the pile diameter range of 2 times of the pile top. Rubber or other elastic materials 10 are filled in the connection gap between the cap opening and the pile. The landfill material can reduce the influence of the impact force while transmitting the contact stress, and realize th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com