Microalgae culture solution treatment method

A microalgae culture solution and microalgae technology, applied in the field of industrial microbiology, can solve problems such as the difficulty of separating microalgae

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

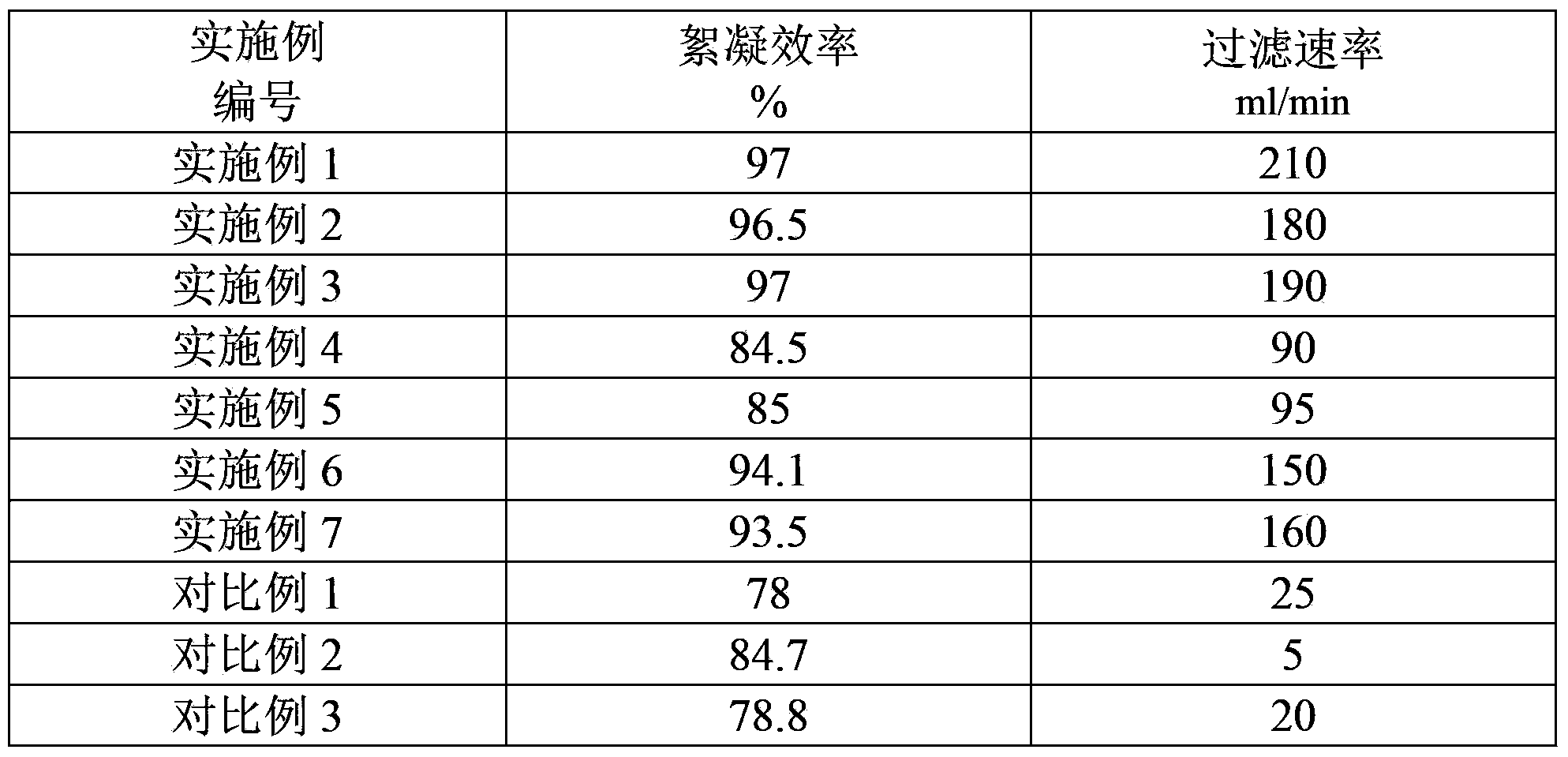

Examples

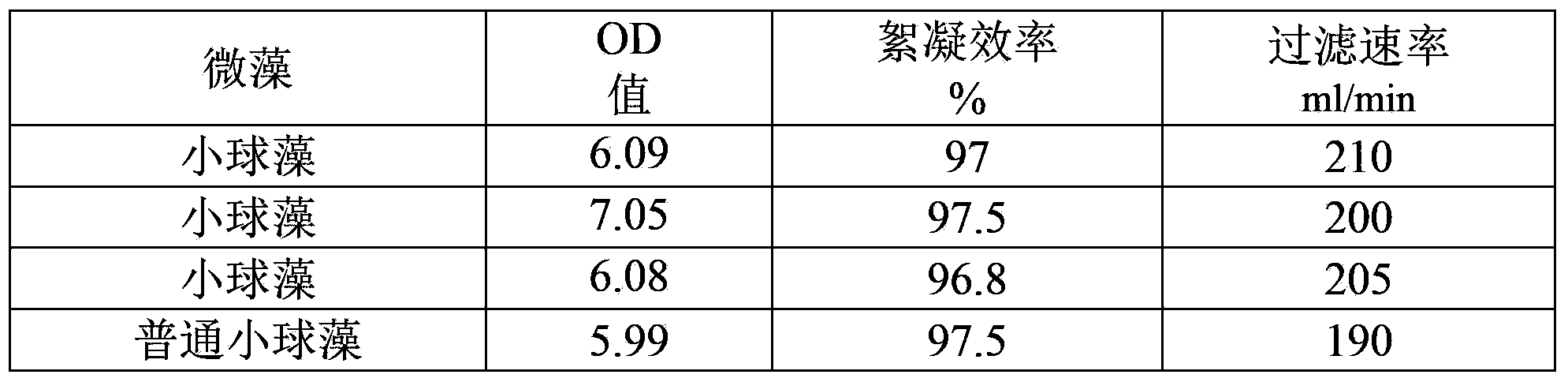

preparation Embodiment 1

[0030] Chlorella sorokiniana was cultivated according to the method in the literature (“Effects of different media and compositions on the growth and oil of two types of Chlorella” Hu Huihui, Xu Nianjun, Journal of Biology, 2012.29 (4) 12-16). Chlorella sorokiniana was purchased from ATCC with item number 22521 TM , obtained 4 parts of Chlorella culture solution altogether, the OD value of the first part of Chlorella culture solution was 5.99, and the pH value was 8.69; the OD value of the second part of Chlorella culture solution was 6.09, and the pH value was 8.87; the third part The OD value of the chlorella culture solution was 7.05 and the pH value was 8.31; the OD value of the fourth chlorella culture solution was 6.08 and the pH value was 8.54.

[0031] Cultivate Chlorella vulgaris according to the method in the literature (“Effects of Different Medium and Composition on the Growth and Oil of Two Kinds of Chlorella” Hu Huihui, Xu Nianjun, Journal of Biology, 2012.29 (4)...

Embodiment 1

[0033] At room temperature, take 800 mL of the first chlorella culture solution in Preparation Example 1 with an OD value of 5.99 and a pH value of 8.69, add 1 mol / L aqueous sodium hydroxide solution under stirring at 100 rpm, and adjust the pH value to 11 . Then under stirring at 100rpm, with respect to 1 volume part of microalgae culture solution with adjusted pH value, add 0.005 volume part of flocculant solution, stir for 30 minutes after the addition is completed, and then let stand for 30 minutes to obtain the treated microalgae Algae culture medium.

[0034]Among them, the flocculant solution is formed by dissolving chitosan (purchased from Sinopharm Chemical Reagent Co., Ltd., batch number F20100408, viscosity 50-800mPa·s, N-deacetylation degree 80-95%) and acetic acid in water in sequence An aqueous solution containing 10 mg / L chitosan and 50 mg / L acetic acid.

Embodiment 2

[0036] At room temperature, take 800 mL of the first chlorella culture solution in Preparation Example 1 with an OD value of 5.99 and a pH value of 8.69, and add 1 mol / L aqueous sodium hydroxide solution under stirring at 100 rpm to adjust the pH value to 11.5 . Then under stirring at 100rpm, with respect to 1 volume part of the microalgae culture solution with adjusted pH value, add 0.002 volume part of flocculant solution, stir for 10 minutes after adding, and then stand for 40 minutes to obtain the treated microalgae Algae culture medium.

[0037] Among them, the flocculant solution is formed by dissolving chitosan (purchased from Sinopharm Chemical Reagent Co., Ltd., batch number F20100408, viscosity 50-800mPa·s, N-deacetylation degree 80-95%) and acetic acid in water in sequence An aqueous solution containing 0.1 mg / L chitosan and 100 mg / L oxalic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com