Mine water magnetic separation water purification process and device used in coal mine

A water purification and magnetic separation technology, which is applied in water/sewage treatment equipment, water/sewage treatment, mining wastewater treatment, etc. It can solve the problems of slow flocculation reaction process, low purification efficiency, and the quality of effluent needs to be improved, and achieve the improvement effect. , high recovery rate, shorten the effect of flocculation mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

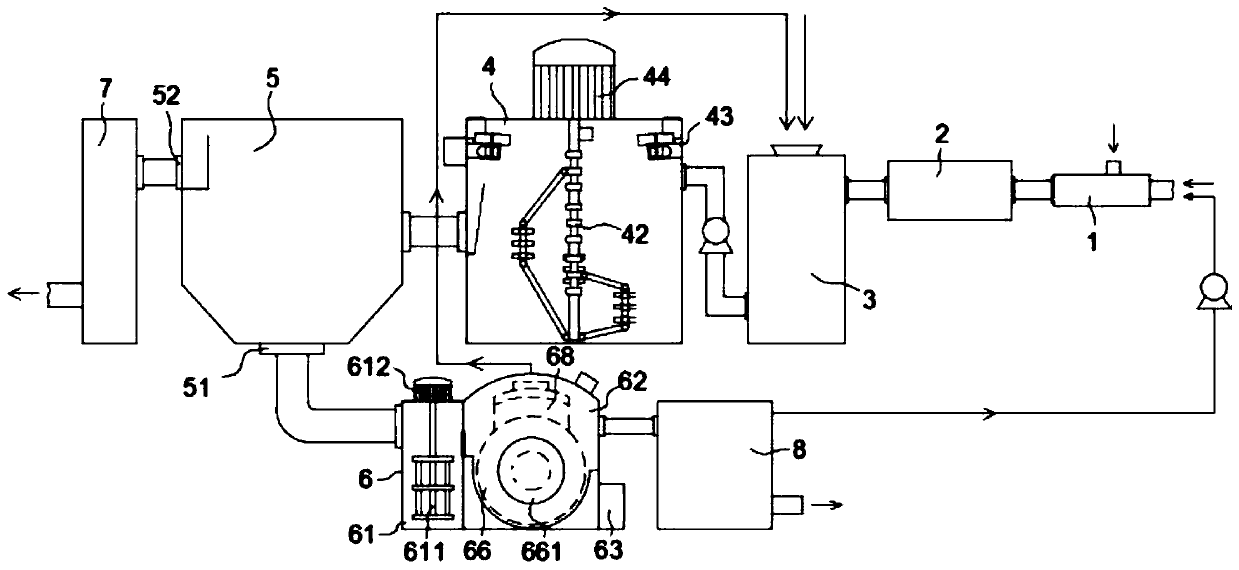

[0048] Such as figure 1 As shown, a mine water magnetic separation water purification equipment used in underground coal mines mainly includes pipeline mixer 1, coagulation tank 2, magnetic seed addition tank 3, flocculation device 4, sedimentation tank 5, magnetic separation device 6, and water purification Treatment device 7, sludge dehydrator 8; water purification post-treatment device adopts activated carbon adsorption purification;

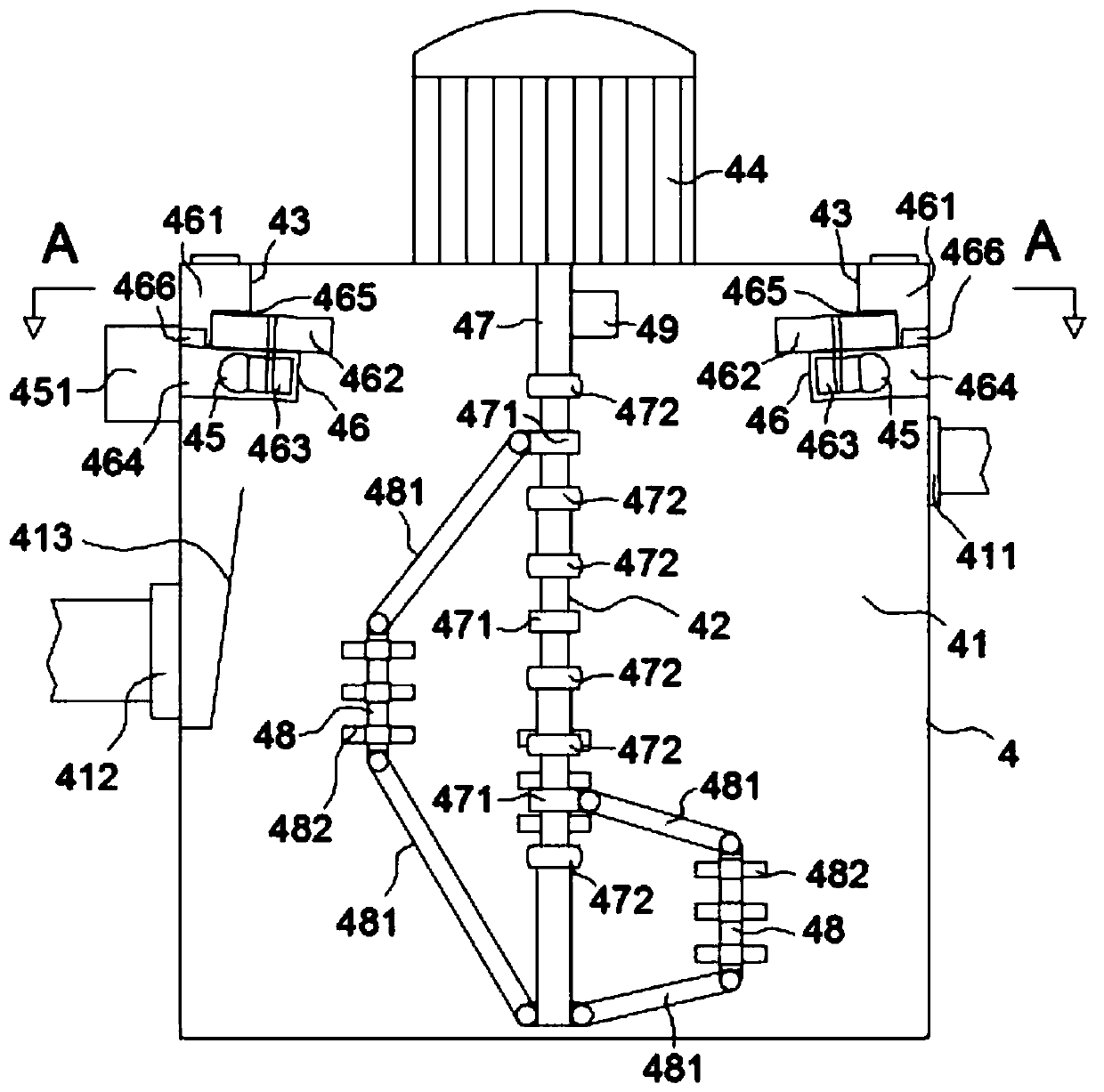

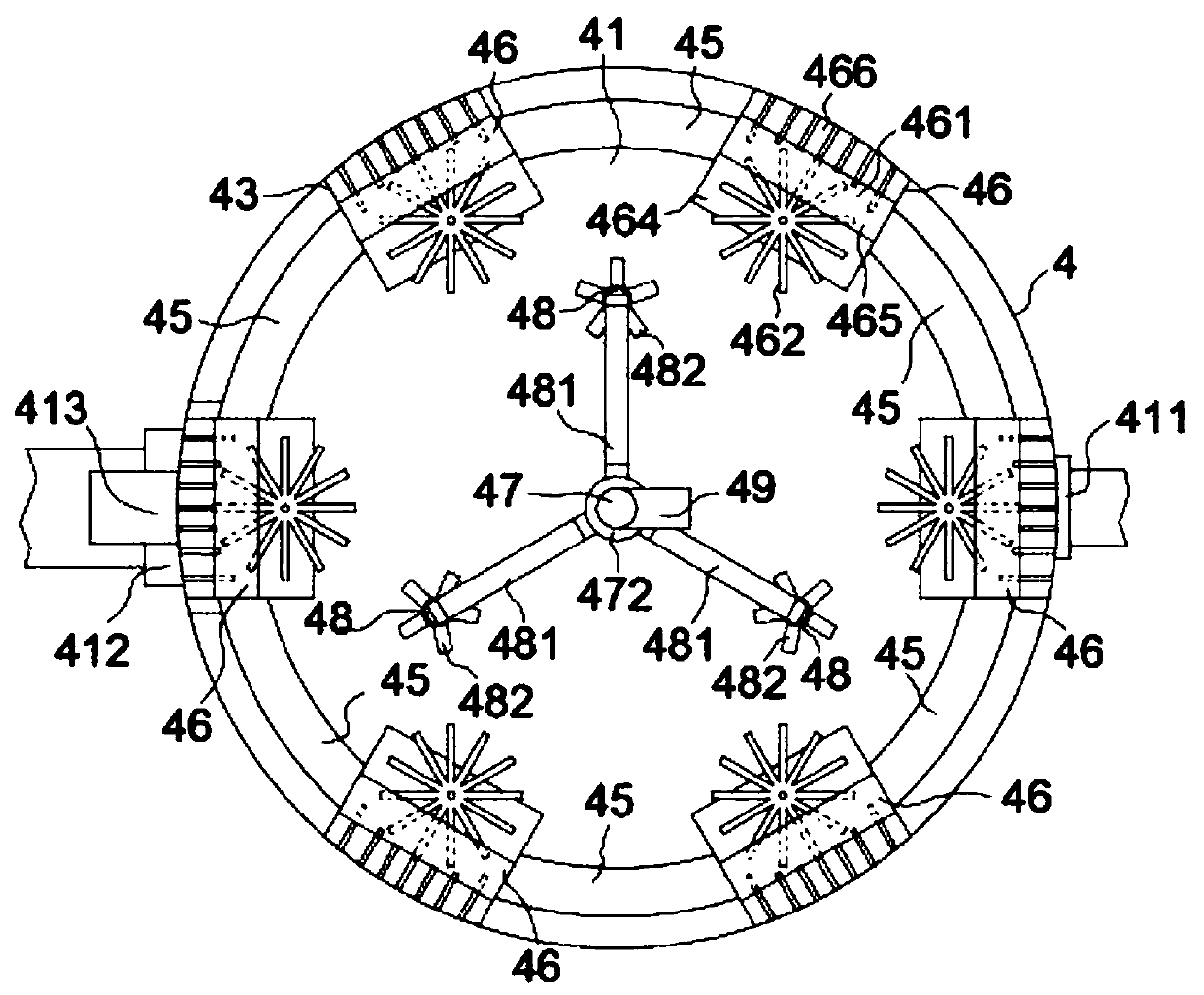

[0049] Such as Figure 2-3 As shown, the flocculation device 4 includes a flocculation chamber 41, a disorderly agitator 42, a dosing device 43, and a drive motor 44; the dosing device 43 is provided with a connecting air pipe 45, a dosing device 46, a circulating air pump 47, and a dosing device 46 There are multiple, arranged on the upper part of the surrounding wall of the flocculation bin body 41 at equal intervals in the circumferential direction; the dosing device 46 includes a drug storage bin 461, a drug-distributing leaf 462, a transmiss...

Embodiment 2

[0066] Embodiment 2 is basically the same as embodiment 1, and differs from embodiment 1 in that:

[0067] A water purification process for magnetic separation of mine water used in underground coal mines includes the following steps:

[0068] S1: Inject the mine water through the inlet end of the pipeline mixer 1, and at the same time, the volume flow rate of the mine water is 53g / m 3 The coagulant is added and mixed, and coagulated in the coagulation tank 2 to obtain coagulated mine water; the coagulant consists of 27 parts by weight of ferric chloride, 3 parts of aluminum sulfate, 2 parts of volcanic rock powder, 7 It is composed of one part of ionic polyacrylamide and one part of alkanolamide. The coagulant composed of the above-mentioned ratio has good coagulation effect. The addition of volcanic rock powder can promote the coagulation treatment and increase the degree of coagulation. The addition of alkanolamide can enhance the purification effect and improve the purified wat...

Embodiment 3

[0075] Example 3 is basically the same as Example 1, but differs from Example 1 in that:

[0076] A water purification process for magnetic separation of mine water used in underground coal mines includes the following steps:

[0077] S1: Inject the mine water through the inlet end of the pipeline mixer 1, and at the same time reduce the volume flow of the mine water to 62g / m 3 The coagulant is added and mixed, and coagulated in the coagulation tank 2 to obtain coagulated mine water; the coagulant consists of 30 parts by weight of ferric chloride, 5 parts of aluminum sulfate, 3 parts of volcanic rock powder, 8 parts by weight It is composed of one part ionic polyacrylamide and two parts alkanolamide. The coagulant composed of the above-mentioned ratio has good coagulation effect. The addition of volcanic rock powder can promote the coagulation treatment and increase the degree of coagulation. The addition of alkanolamide can enhance the purification effect and improve the purified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com