Method for preparing adhesive from waste polystyrene foam plastic

A waste polystyrene, waste polystyrene technology, applied in the direction of hydrocarbon copolymer adhesives, adhesive types, rosin adhesives, etc., can solve the damage to the ecological environment, complex production process, difficult to promote and apply problems, to achieve the effect of less investment, full utilization of resources and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] According to the following mass content %, it is PS: 34%, SBS: 5.6%, commercially available petroleum cracking by-products: 50%, ethyl acetate: 5%, rosin: 1.1%, dibutyl phthalate: 1.7%, Sodium dodecylbenzenesulfonate: 1.3%, OP-10: 1.3% prepare each raw material.

[0017] Then descale and crush the waste polystyrene foam and place it in a container, add the selected commercial petroleum cracking by-product mixture at room temperature, fully dissolve and stir evenly; at the same time, heat the ethyl acetate water bath to about 40°C , slowly add SBS, stir rapidly until the SBS is completely dissolved, and cool to room temperature.

[0018] Mix the solution of waste polystyrene foam with the solution of SBS, stir well, add rosin, stir fully until completely dissolved, then add emulsifier sodium dodecylbenzene sulfonate, OP-10 and The plasticizer dibutyl phthalate is mixed and stirred evenly to obtain the adhesive.

Embodiment 2

[0019] Embodiment two: performance test experiment

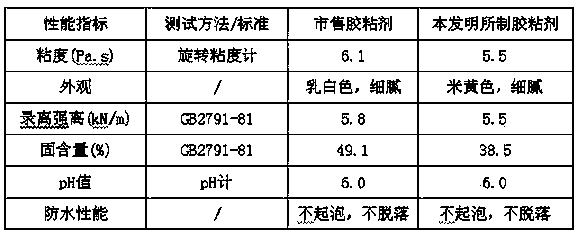

[0020] According to the performance test of the modified adhesive prepared according to the optimal process requirements of the present invention, and compared with the commercially available adhesive, the comparison results are shown in Table-1.

[0021] Table-1 Comparison Results

[0022]

[0023] The experimental results show that the prepared adhesive has excellent performance and is suitable for bonding wood, paper, fiber and other products. It has good bonding strength and can replace neoprene for wood edge sealing, and can also be mixed with certain A small amount of cement can be used instead of strong floor glue for pasting decorative materials such as parquet floors, ceramic tiles, and mosaics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com