Polymer cement water-proof coating and preparation method thereof

A waterproof coating and polymer technology, applied in the field of chemical building materials, can solve problems such as dust generation, affecting the health of builders, and polluting the environment, and achieve the effects of good environmental protection, good extension performance, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

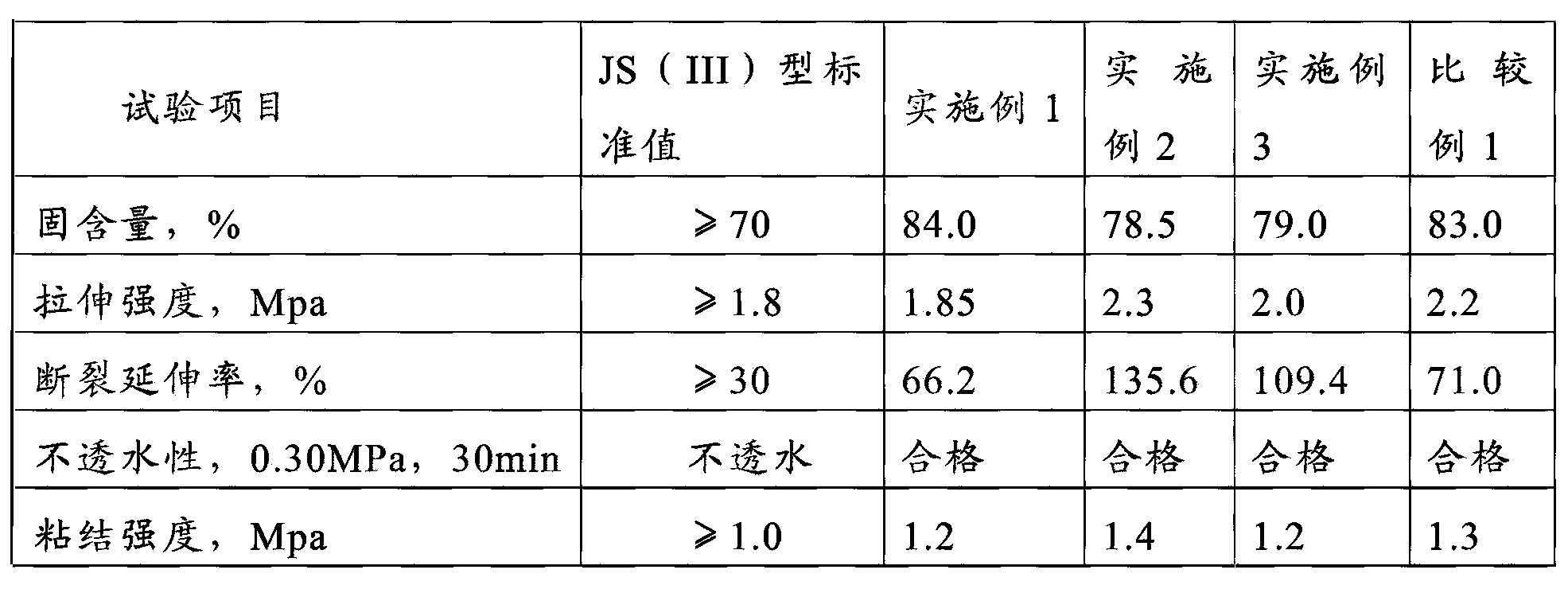

Examples

preparation example Construction

[0056] The present invention also discloses a preparation method of the polymer cement waterproof coating described in the above technical solution, comprising the following steps:

[0057] (A) Mix and stir 85-95wt% polymer emulsion, 0.5-1.0wt% defoamer, 0.02-0.1wt% preservative and 4-14wt% water to obtain a liquid material;

[0058] Add 0.05-1.6wt% dust suppressant heated and atomized to the mixture of 30-50wt% cement, 39-50wt% quartz sand and 10-20wt% heavy calcium to obtain powder; the dust suppressant is C2~ One or more of C8 diols, oligomers of diols, and esters formed by oligomers of diols;

[0059] The degree of polymerization of the oligomers of dihydric alcohols is less than 10;

[0060] (B) Mix the liquid material and the powder material according to the mass ratio of 1:1.0-2.5 to obtain the polymer cement waterproof coating.

[0061] In the present invention, liquid material and powder material are prepared respectively at first. In the process of preparing the l...

Embodiment 1

[0067] Add 1000Kg of styrene-acrylic emulsion to the mixing tank, then add 150Kg of water, 10Kg of defoamer, and 0.5Kg of preservative in turn under low-speed stirring. Stir for 20 minutes, filter with a 50-mesh filter, that is, the liquid material, put it in a plastic bucket and seal it for later use.

[0068] Add 100Kg of 42.5 ordinary Portland cement, 125Kg of quartz sand, and 30Kg of heavy calcium into the powder mixer in turn, stir for 4 minutes, and mix well; heat 3Kg of dust suppressant dipropylene glycol dibenzoate to 75°C, put In the atomizer; in the state of stirring, the dust suppressant is added to the mixture in the form of atomization, so that the liquid and powder are fully mixed, that is, the powder. Pack airtightly in a plastic bag. Mix the liquid material and powder evenly at a weight ratio of 1:2.2, and apply it on the PTFE mold twice by scraping. The dry film thickness is controlled at (1.5±0.2) mm, cured for 4 days under standard conditions, placed in an...

Embodiment 2

[0080] Add 1000Kg of acrylic emulsion to the mixing tank, and add in order under low-speed stirring, 70Kg of water, 6Kg of defoamer, and 0.5Kg of preservative. Stir for 20 minutes, filter with a 50-mesh filter, that is, the liquid material, put it in a plastic bucket and seal it for later use.

[0081] Add 100Kg of 42.5 ordinary Portland cement, 120Kg of quartz sand, and 30Kg of heavy calcium into the powder mixer in turn, stir for 4 minutes, and mix well; add dust suppressants diethylene glycol dibenzoate and dipropylene glycol dibenzoate Heat 3Kg of the ester mixture (weight ratio 50 / 50) to 75°C and put it into the atomizer; while stirring, add the dust suppressant to the mixture in the form of atomization to make the liquid and powder fully Mixed, that is, powder. Pack airtightly in a plastic bag.

[0082] Mix the liquid material and the powder material uniformly at a weight ratio of 1:1.2 to obtain a polymer cement waterproof coating.

[0083] The method of Example 1 wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com