Micro-slot plastic disc serial aerator

A technology of plastic discs and aerators, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problem of low oxygen utilization rate, increased operating resistance loss, uneven bubbles, etc. problems, to achieve the effect of simple and easy structure, stable and reliable operation, and uniform bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below with reference to accompanying drawing, the present invention is described for implementing method, and this description is only an example. The present invention is not limited, and those skilled in the present invention can make equivalent replacements or changes to be equivalent to other embodiments.

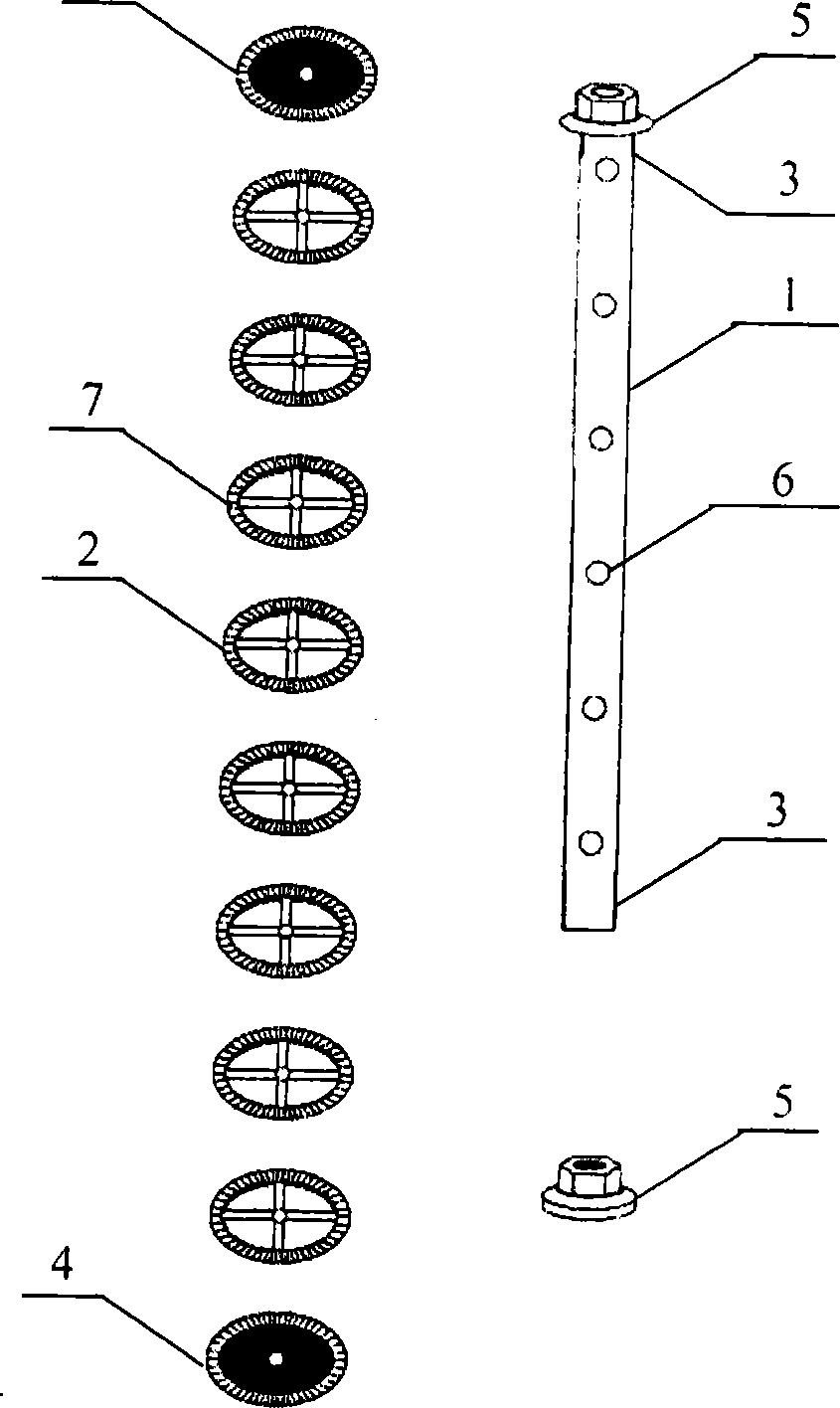

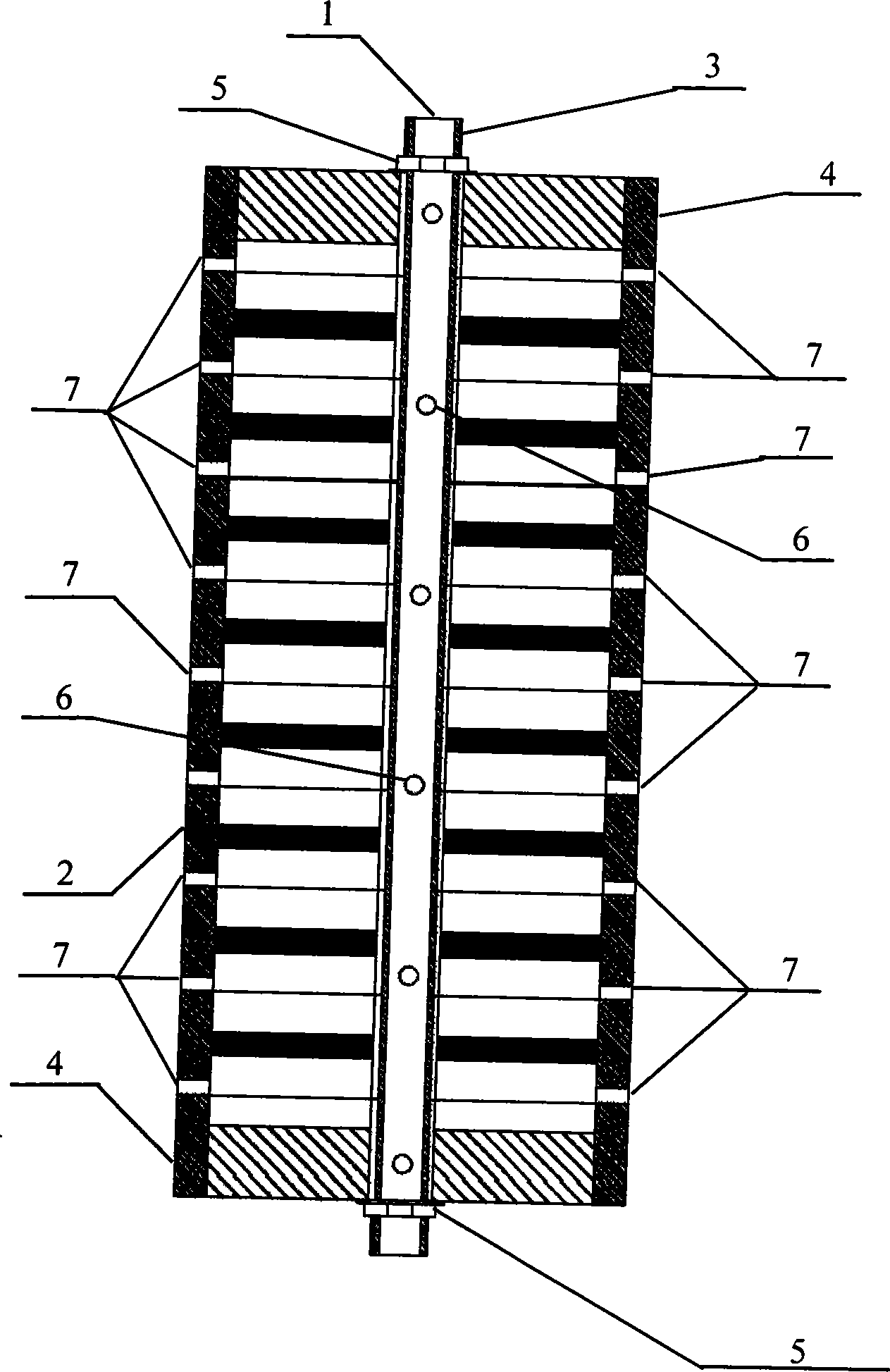

[0014] Such as figure 1 , shown in 2, the present invention is by perforated pipe connecting rod 1 (this pipe of perforated pipe connecting rod needs perforation 6), and micro groove plastic aeration disc 2 is stringed on the perforated pipe connecting rod. The two ends of the perforated pipe connecting rod have overcoat wire 3, and in the plastic disc surface at both ends of the aerator is air-tight sheet material 4, and fixing nut 5 is fixed (micro-groove plastic disc and two ends air-tight sheet material plastic disc surface). A plurality of micro grooves 7 are arranged on one side of the contact cross-section between each plastic disc (2) to form an air outl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com