Stamping type radian regulating device

An adjusting device, stamping technology, applied in grinding/polishing safety devices, grinding workpiece supports, grinding machines, etc., can solve the problems of uneven inner surface of enamel tank, stamping damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

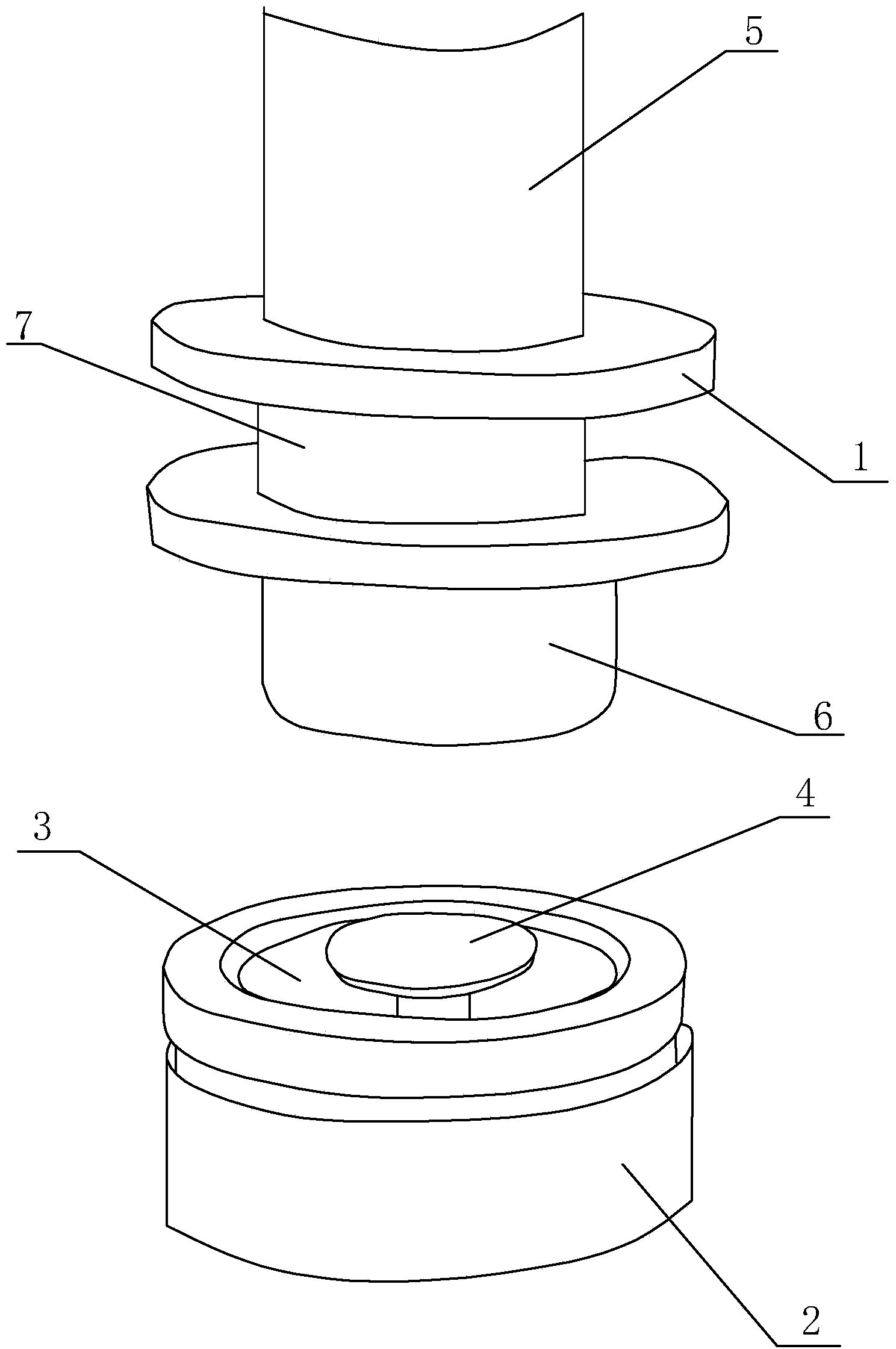

[0010] Such as figure 1 As shown, a stamping arc adjustment device includes a cylinder (not shown in the figure), a pressing plate 1 and a workbench 2; the workbench 2 is provided with a cylindrical cavity 3, and inside the cylindrical cavity 3 A lifting platform 4 is provided, and when the lifting platform 4 rises to the highest point, it is flush with the upper edge of the workbench 2, and when the lifting platform 4 descends to the lowest point, it is flush with the bottom of the cylindrical cavity 3; the cylinder is perpendicular to the ground , a pressure plate 1 is fixed under the piston rod 5 of the cylinder, a buffer device 7 is arranged under the pressure plate 1, and a cylindrical grinding stone 6 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com