Device for molding ceramic core of directionally solidified blade

A ceramic core and directional solidification technology, which is applied in the direction of core, mold composition, mold, etc., can solve problems such as low assembly accuracy, cracks, and failure to remove ceramic cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

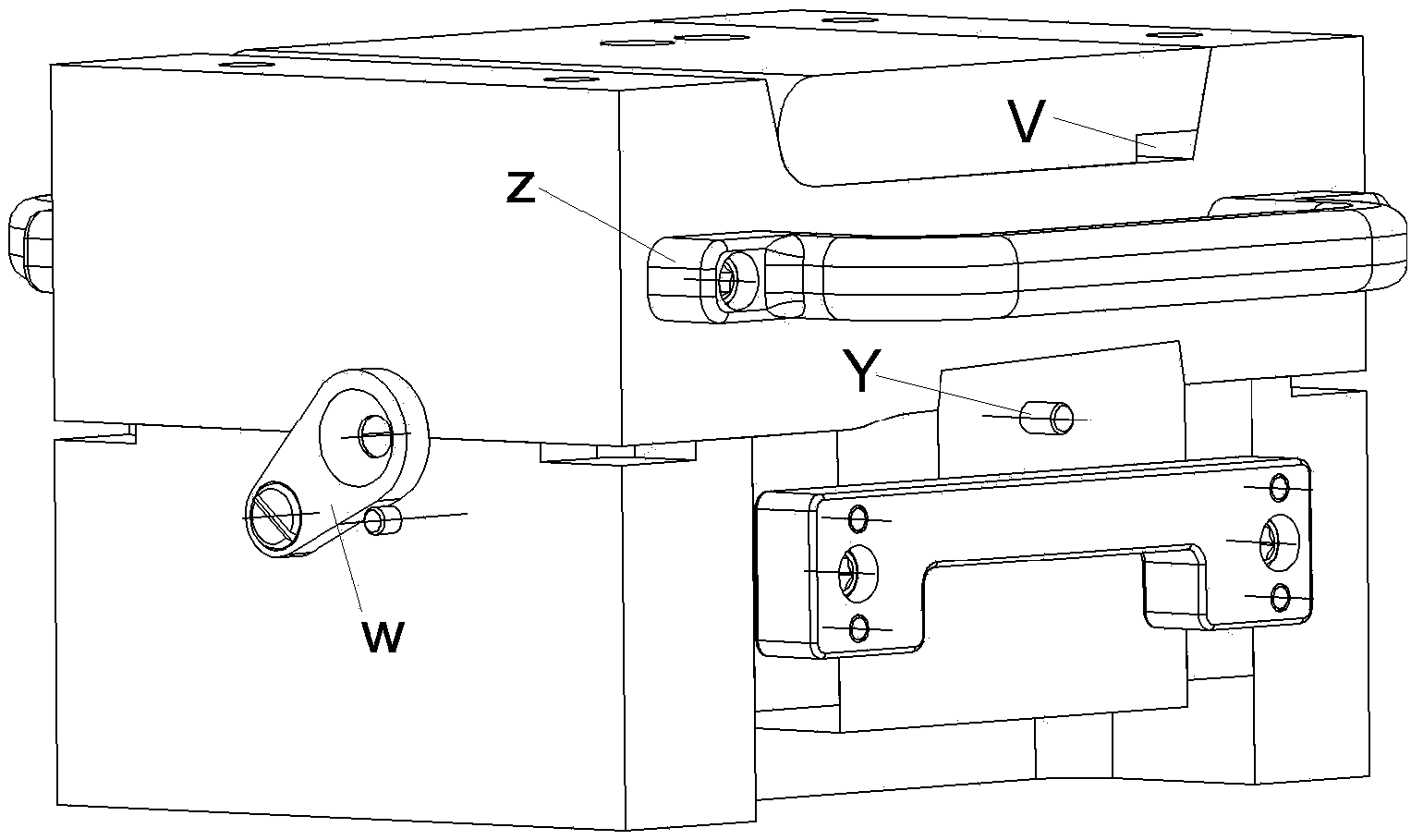

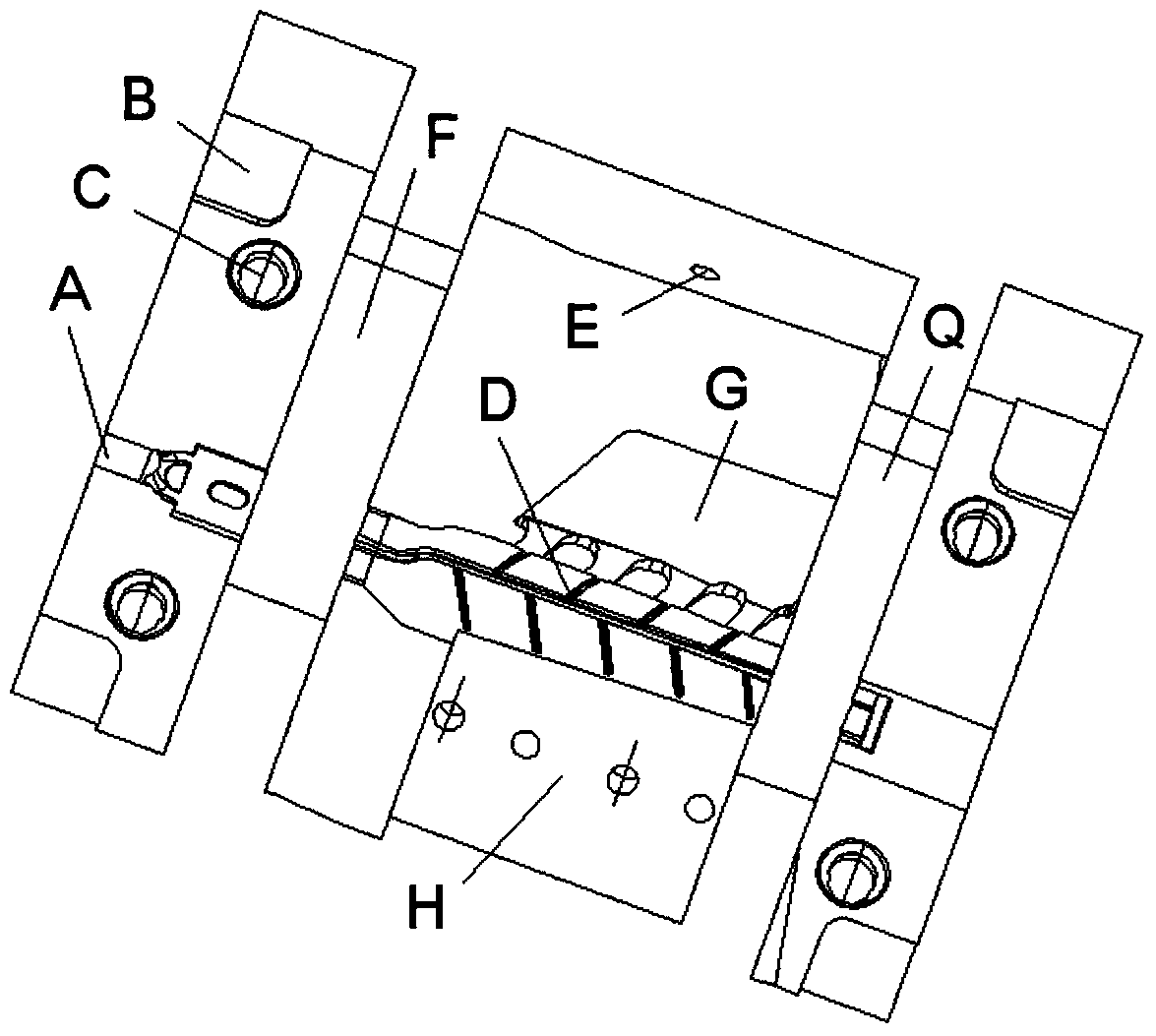

[0029] The directional solidification vane ceramic core forming device has a cuboid structure as a whole, see the attached figure 1 , the material of the directional solidification blade ceramic core forming device is P20, and the overall parting surface is a composite of a plane and a complex curved surface.

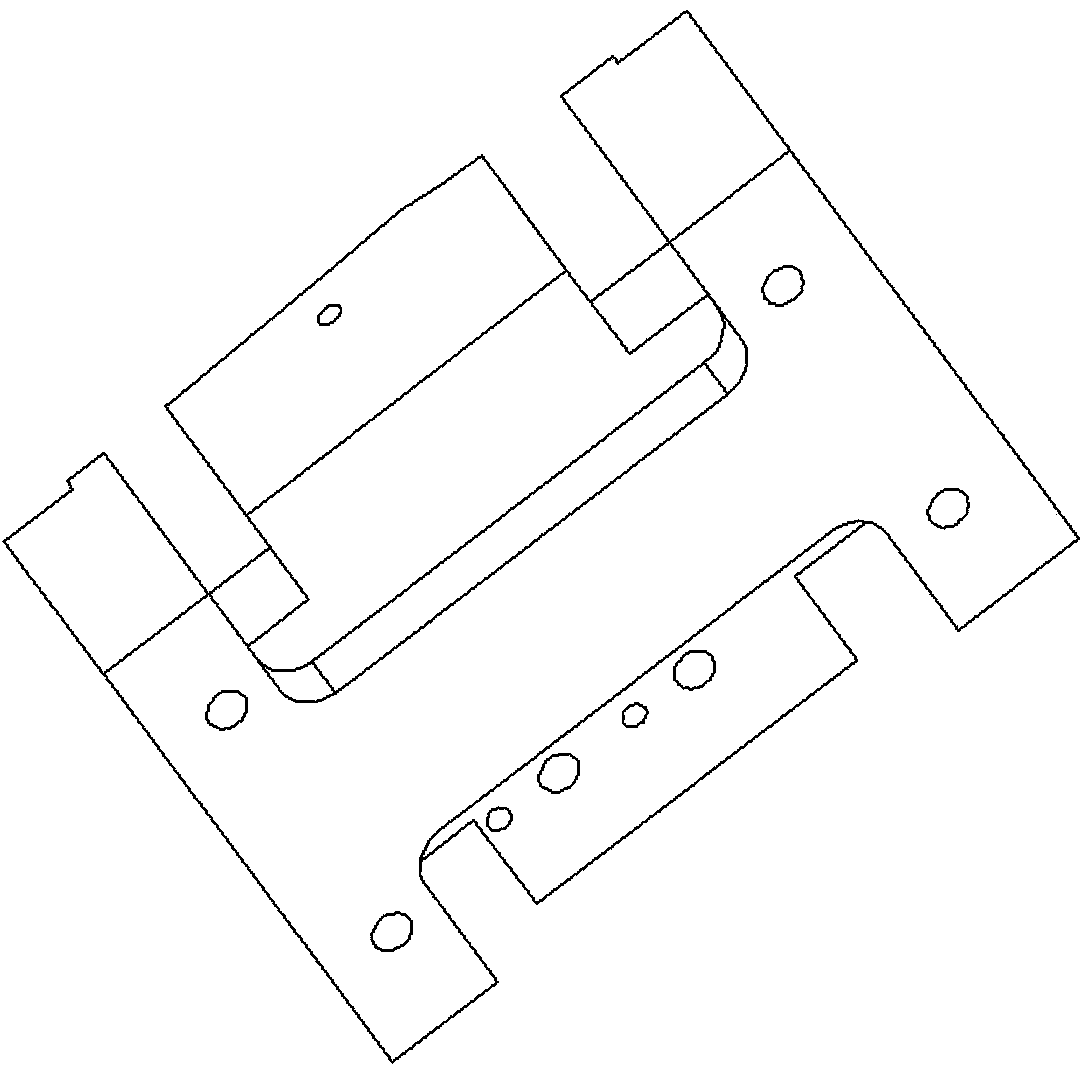

[0030] The directional solidification blade ceramic core forming device is constituted as follows: an upper template 1, an upper mold 2, a lower mold 3, an upper mold movable block 4, an upper mold pressing compacting block 5, a lower mold movable block 6, and a lower mold insert 7 , the front movable block 8 of the lower mold, the rear movable block 9 of the lower mold, the linkage plate 10, the front edge movable block 11, the wax injection plate 12, the stepped screw 13, the handle 14 and the positioning pin 15;

[0031] The lower mold 3 includes: the front side a of the lower mold and the bottom surface b of the lower mold, a core injection port is opened on the lef...

Embodiment 2

[0039] This embodiment is basically the same as Embodiment 1, the difference is:

[0040] The diameter of the core injection port opened at the left side A of the front side a of the lower mold is 8mm.

[0041] The shape of the openings at the four corners B of the front side a of the lower mold is square, and one side is rounded, and the sinking is 1.5 mm.

Embodiment 3

[0043] This embodiment is basically the same as Embodiment 1, the difference is:

[0044] The diameter of the core injection hole opened at the left side A of the front side a of the lower mold is 6-7mm.

[0045] The pry openings at the four corners B of the front side a of the lower mold are square in shape, and one side thereof is rounded, and sinks by 3.5 mm to 5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com