Coating material dispersion apparatus capable of making coating material forward rotate and reverse rotate

A dispersing device, forward and reverse technology, applied in mixers with rotating stirring devices, dissolving, mixers and other directions, can solve problems such as dead ends, affecting the working efficiency of paint dispersion devices, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

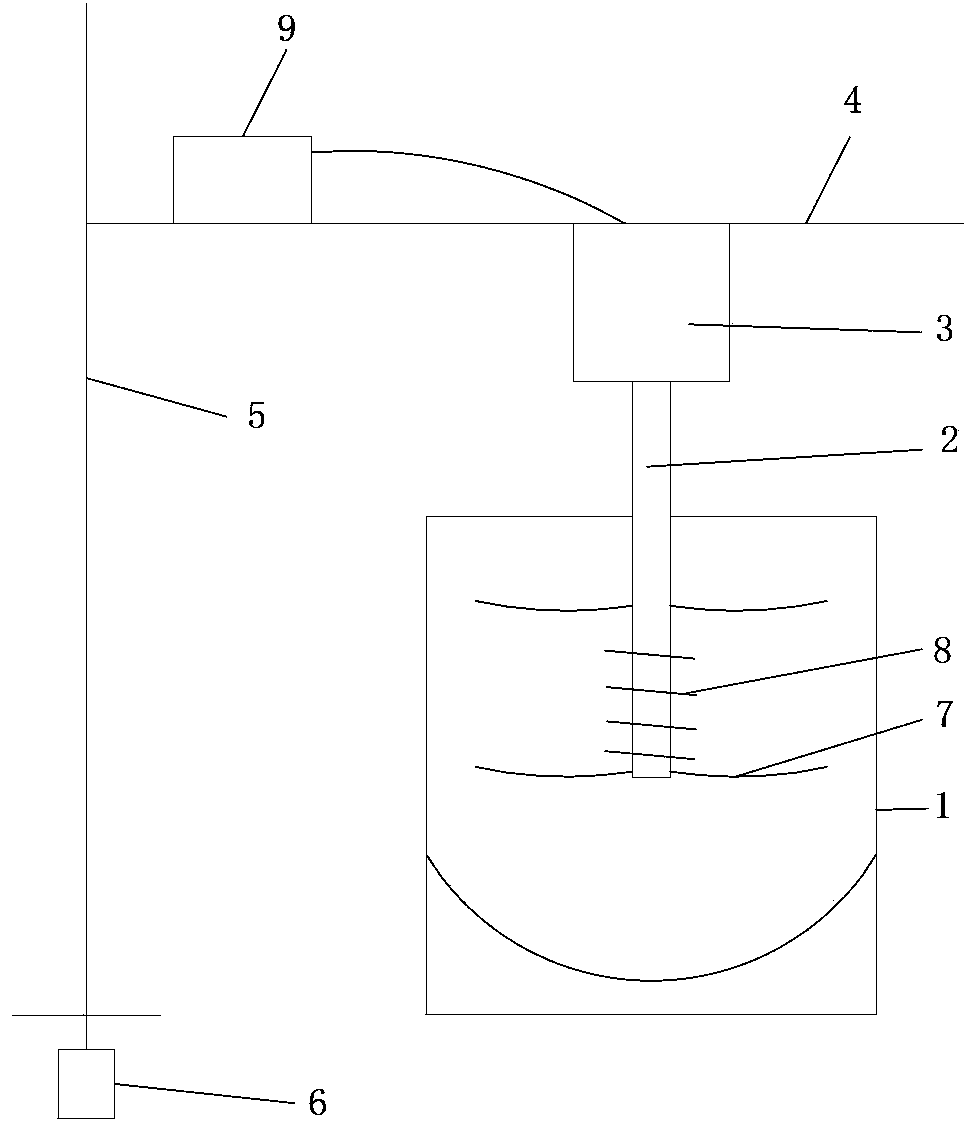

[0015] refer to figure 1 , a coating dispersing device with forward and reverse rotation of the present invention, including a stirring container 1, a rotating shaft 2, a rotating motor 3, and a support frame. The rotary motor 3 is fixed on the support frame, and the support frame is composed of a support plate 4, a support rod 5 and an oil cylinder 6, one end of the support plate 4 is fixed to the support rod 5, the support rod 5 is fixedly connected to the oil cylinder 6, and the rotary motor 3 is fixed on the support plate 4. The support frame of this structure, driven by the oil cylinder, makes the support rod 5 and the support plate 4 move up and down accordingly, thereby providing a guarantee for the comprehensive dispersion of the material by the spiral blade and the stirring blade. The output end of the rotary motor 3 is connected with the rotary shaft 2 . The lower part of the rotating shaft 2 is located in the stirring container 1, and the lower part of the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com