Fabric composite film and its preparation method and application

A composite film and fabric technology, applied in chemical instruments and methods, diaphragm structures, synthetic resin layered products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

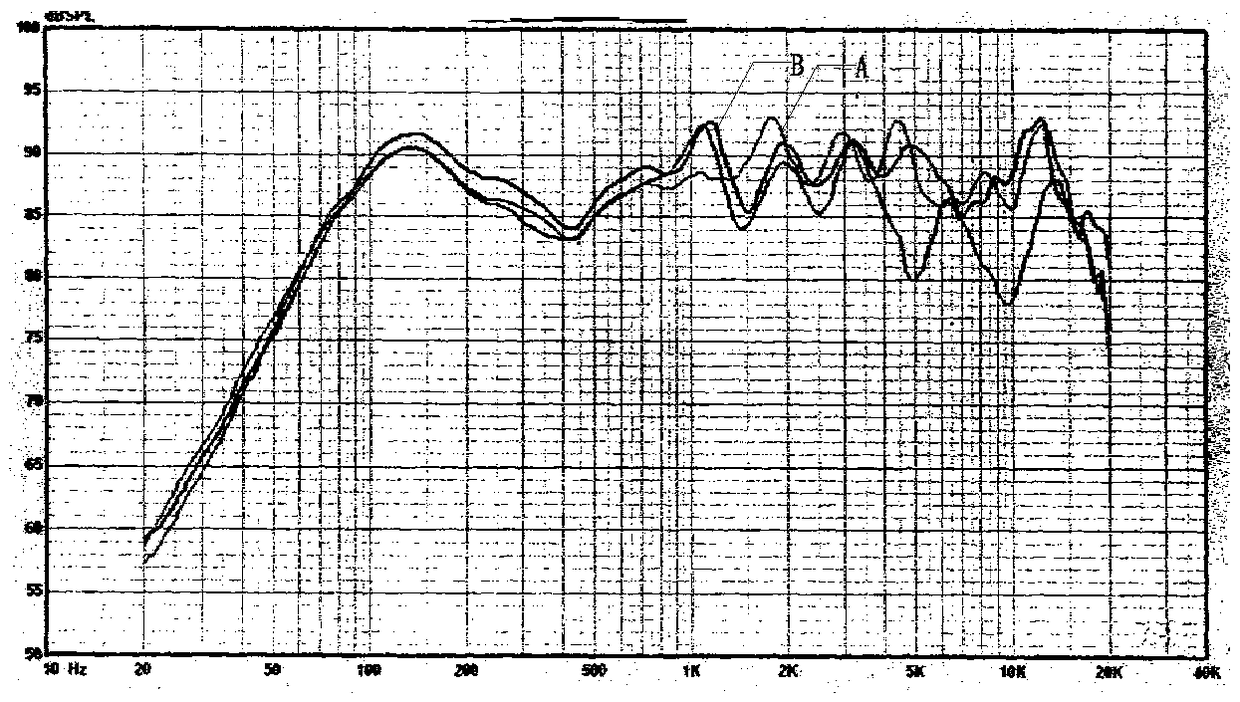

Image

Examples

Embodiment 1

[0070] The preparation method of fabric composite film, comprises the following steps:

[0071] Step 1: Put the resin film on the roll, and apply adhesive glue, the glue amount is 8g / m 3 , the roller tension on the resin film is 0.5kgf / m 2 ;

[0072] Step 2: Attach the cloth to the resin film, the lamination tension of the cloth is 0.1kgf / m 2 .

[0073] The thickness of the resin film is 0.10mm, and the tensile strength of the resin film is 50kg / cm 2 , the elongation of the resin film is 500%, and the hardness modulus of the resin film is 10kg / cm 2 .

[0074] The density of the knitted fabric is 30g / m 3 , the tensile strength of the knitted fabric is 1kg / cm 2 .

[0075] The resin film in this embodiment is a TPU film. The fabric composite film material prepared by the above method can be applied to the speaker edge material.

Embodiment 2

[0077] The preparation method of fabric composite film, comprises the following steps:

[0078] Step 1: Put the resin film on the roll, and apply adhesive glue, the glue amount is 16g / m 3 , the roller tension on the resin film is 1kgf / m 2 ;

[0079] Step 2: Attach the cloth to the resin film, the lamination tension of the cloth is 0.4kgf / m 2 .

[0080] The thickness of the resin film is 0.015mm, and the tensile strength of the resin film is 100kg / cm 2 , the elongation of the resin film is 400%, and the hardness modulus of the resin film is 50kg / cm 2 .

[0081] The density of the knitted fabric is 60g / m 3 , the tensile strength of the knitted fabric is 100kg / cm 2 .

[0082] The resin film of this example is a PC film. The fabric composite film material prepared by the above method can be applied to the sound film material of the tweeter dome.

Embodiment 3

[0084] The preparation method of fabric composite film, comprises the following steps:

[0085] Step 1: Put the resin film on the roll, and apply adhesive glue, the glue amount is 280g / m 3 , the roller tension on the resin film is 4kgf / m 2 ;

[0086] Step 2: Attach the cloth to the resin film, the lamination tension of the cloth is 2kgf / m 2 .

[0087] The thickness of the resin film is 0.05mm, and the tensile strength of the resin film is 400kg / cm 2 , the elongation of the resin film is 100%, and the hardness modulus of the resin film is 100kg / cm 2 .

[0088] The density of the knitted fabric is 100g / m 3 , the tensile strength of the knitted fabric is 120kg / cm 2 .

[0089] The resin film of this example is a PEEK film. The fabric composite membrane material is prepared by the above method, which can be applied to the micro horn diaphragm material of the loudspeaker.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com