Conductive spring for pins of power connector

A power connector and pin technology, which is applied in the field of conductive springs, can solve the problems of unfavorable power connector miniaturization, light weight production, large size of power connector, and limited flow capacity, etc., to achieve reliable contact and light weight Make and plug reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

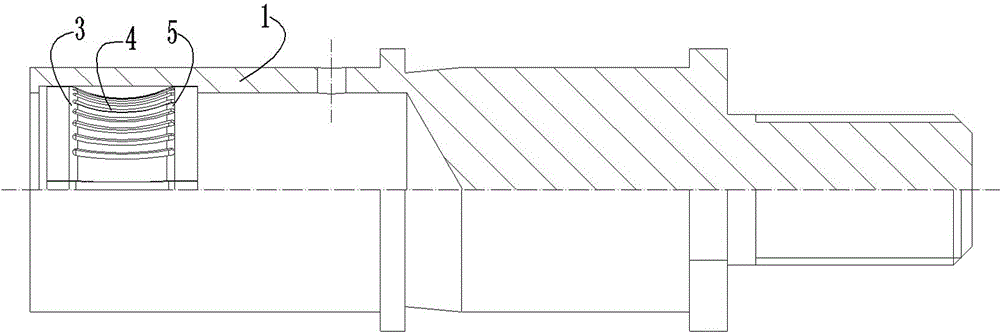

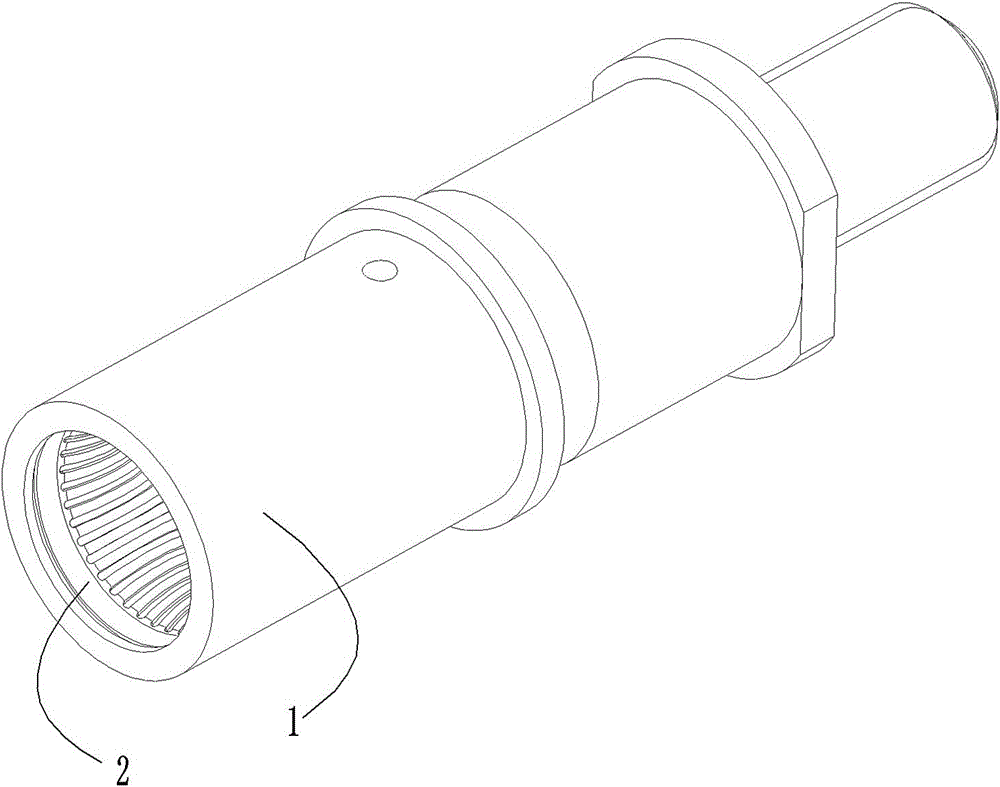

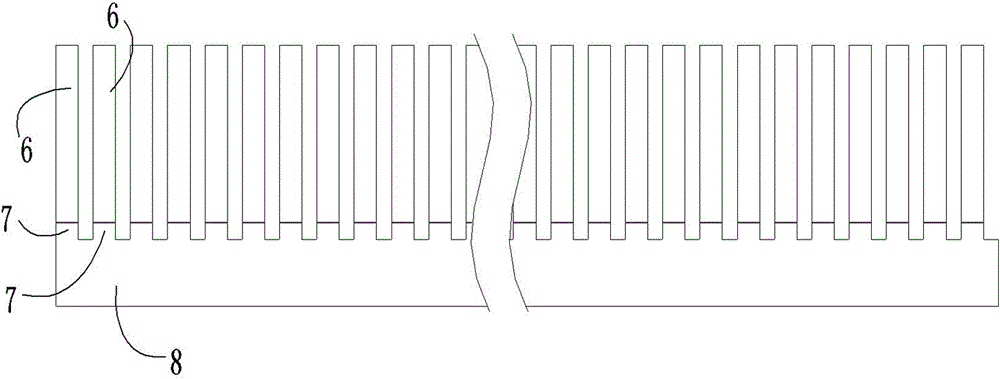

[0021] Examples of conductive springs are Figure 3~8 Shown: The structure of the conductive spring is as follows Figure 3~4 As shown, it includes a strip-shaped flexible base 8 extending along the front-to-rear direction for being wound and fixed on the outer periphery of the corresponding pin during use. The strip-shaped flexible base 8 is a sheet-shaped structure whose thickness extends along the front-to-back direction. The conductive spring also includes a plurality of Elastic contact fingers 6, the lower ends of each elastic contact finger 6 protrude backward respectively and are used for positioning positioning protrusions 7 and strip-shaped flexible substrates 8 inserted in the spiral positioning grooves on the outer peripheral surface of the pins. connection, the upper end of each elastic contact finger 6 is an elastic overhang end elastically overhanging the upper side of the strip-shaped flexible substrate 8 with elastic deformation in the front-rear direction, eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com