High-numerical-aperture optical fiber point diffraction interference device used for three-coordinate measurement and method thereof

A three-coordinate measurement and point diffraction interference technology, which is applied in the field of large numerical aperture optical fiber point diffraction interference devices, can solve the problems of complex production, limited measurement range, low convergence area and easy divergence, etc., and meet the requirements of reducing photosensitivity and expanding measurement Range, Simplify Effects of Adjusting Difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

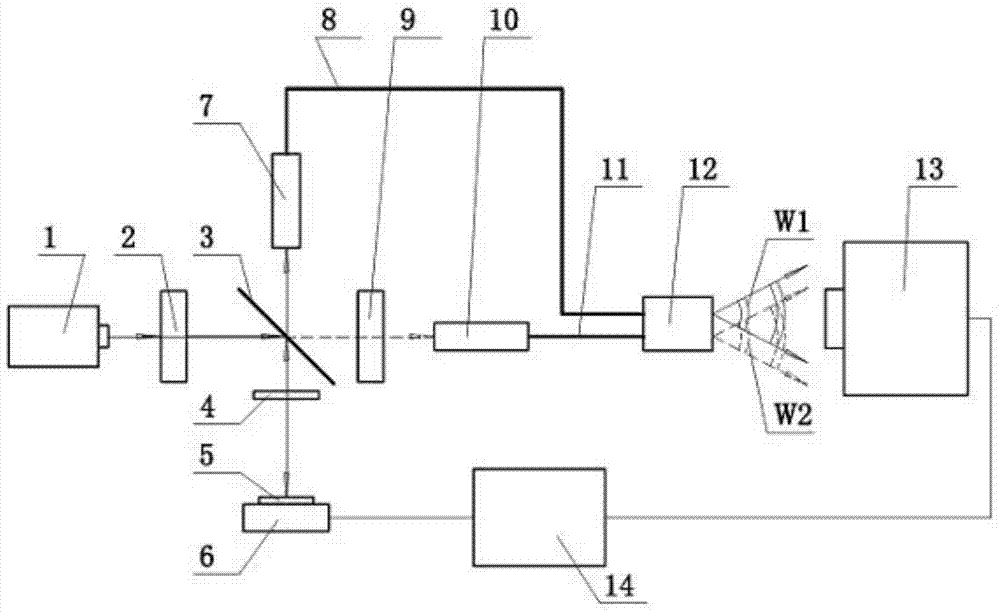

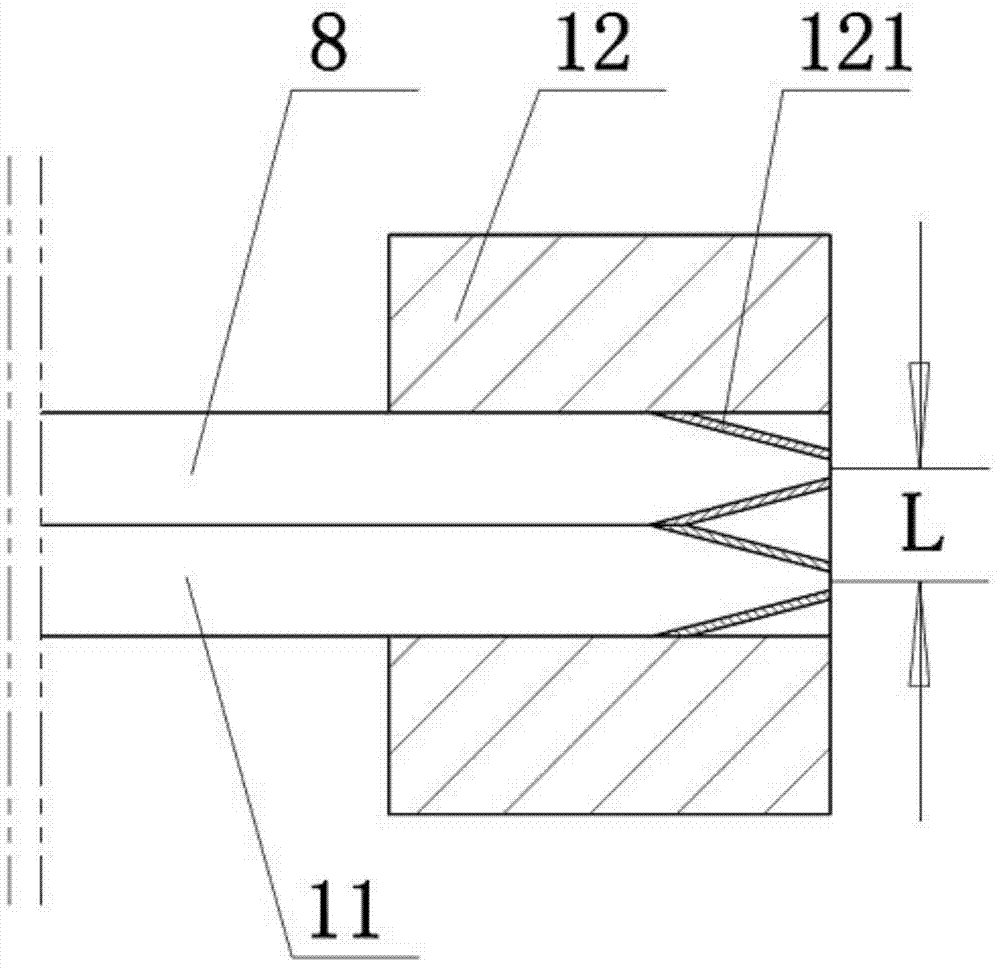

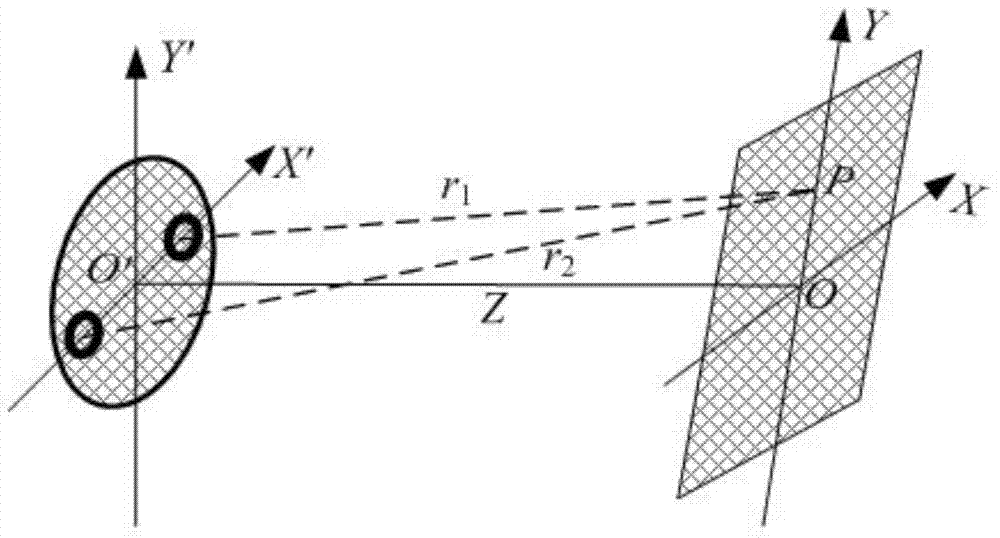

[0017] like figure 1 and 2 As shown, a large numerical aperture fiber point diffraction interference device for three-coordinate measurement, which includes a laser 1, a half-wave plate I2, a polarization beam splitting prism 3, a quarter-wave plate 4, a mirror 5, Phase shifter 6, fiber coupler I7, subwavelength aperture single-mode fiber I8, half-wave plate II9, fiber coupler II10, subwavelength aperture single-mode fiber II11, measuring probe 12, CCD detector 13, computer 14 . figure 1 Thin lines with arrows in the middle represent light, and thin lines without arrows represent circuit connections. Laser 1 is a He-Ne polarized laser. The direction of the fast axis of the quarter-wave plate 4 forms an included angle of 45° with the x-axis. The phase shifter 6 is a piezoelectric ceramic phase shifter with high displacement resolution and high frequency response. The mirror 5 is connected to the end face of the phase shifter 6 . The number of pixels of the CCD detector 13...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com