Device and method for measuring gas pressure by using ultrasonic wave

A gas pressure and ultrasonic technology, used in surveying, earthmoving, wellbore/well components, etc., can solve the problems of inaccurate pressure measurement, poor sealing quality, low pressure measurement efficiency, etc., and achieve accurate and strict measurement. High and time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

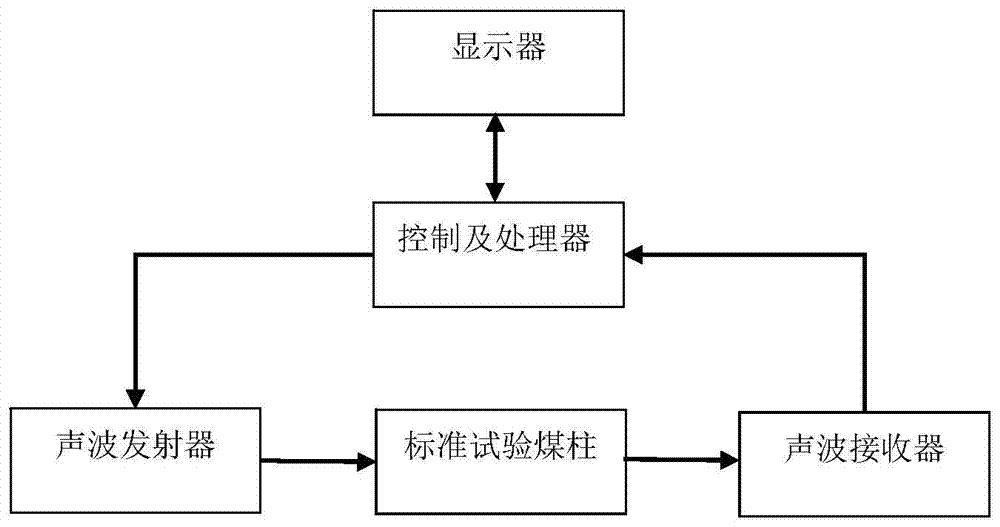

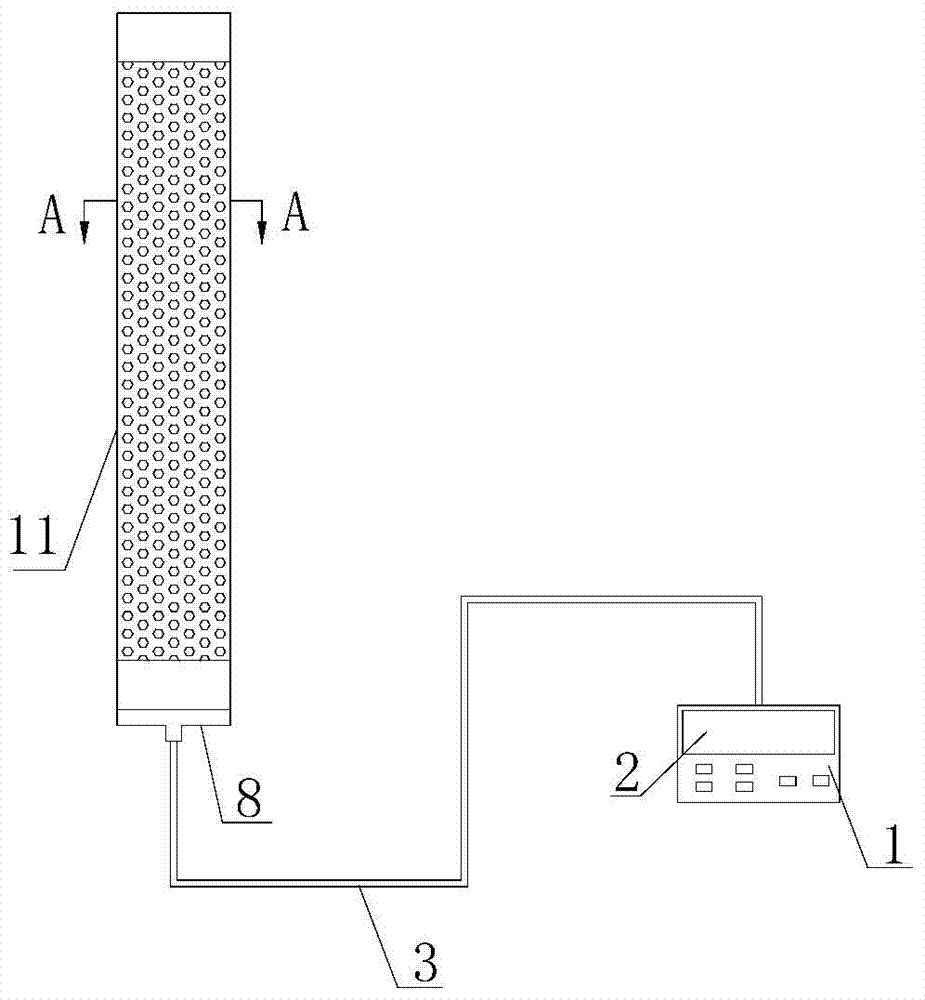

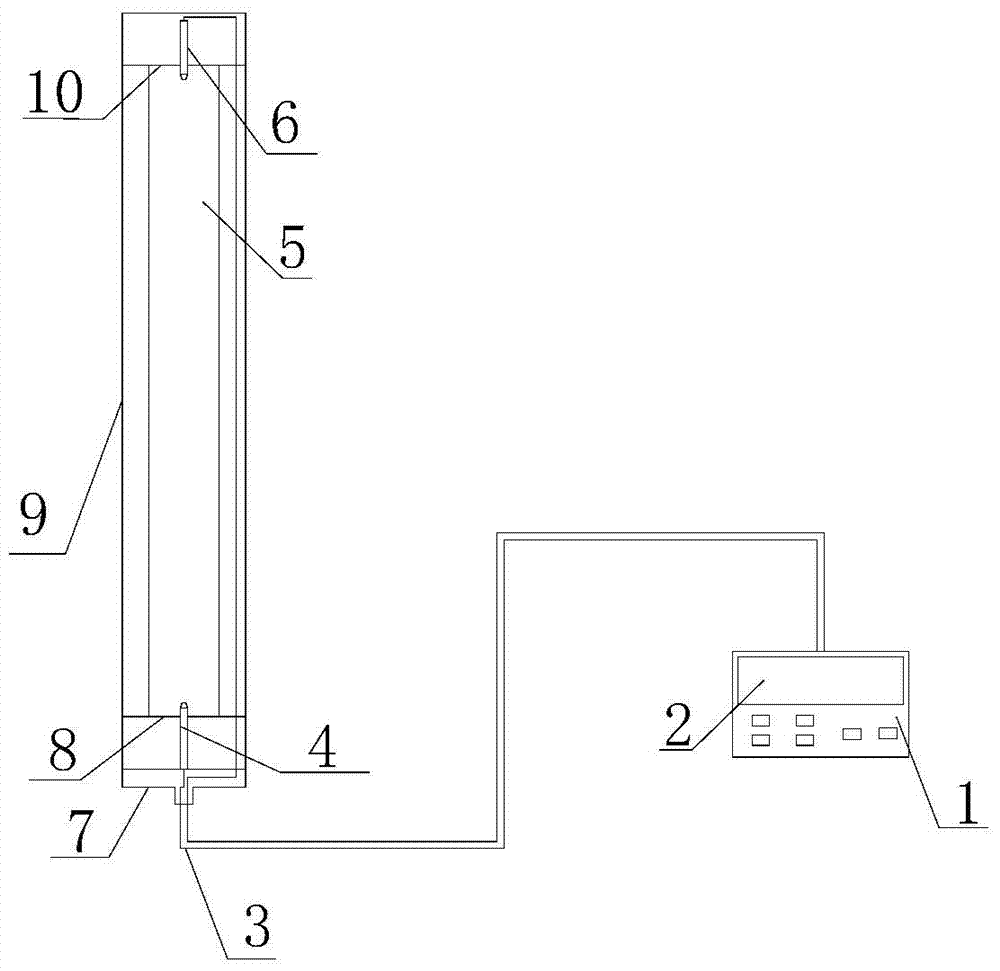

[0028] like figure 1 , figure 2 , image 3 and Figure 4 As shown, a device for measuring gas pressure using ultrasonic waves includes a sonic instrument, a wire 3, a controller and a processor 1, and a display 2. The sonic instrument includes a casing 9, a closing cover 7, a lower coal plate 8, and an upper coal plate 10. Acoustic wave transmitter 4, standard test coal pillar 5 and acoustic wave receiver 6, one end of shell 9 with a length of 500 mm and a diameter of 50 mm is closed, and the other end is open. Made of iron, the outer surface of the shell 9 is covered with mesh holes 11, and the inner surface of the shell 9 is sprayed with a sound-absorbing coating; the standard test coal pillar 5 with a length of 400mm and a diameter of 40mm is placed in the middle of the shell 9, and the standard test coal pillar 5 is complete The complete coal pillar refers to a coal pillar without large cracks or broken coal pillars. One end of the standard test coal pillar 5 is clampe...

Embodiment 2

[0036] like figure 1 , figure 2 , image 3 and Figure 4 As shown, a device for measuring gas pressure using ultrasonic waves includes a sonic instrument, a wire 3, a controller and a processor 1, and a display 2. The sonic instrument includes a casing 9, a closing cover 7, a lower coal plate 8, and an upper coal plate 10. Acoustic wave transmitter 4, standard test coal pillar 5 and acoustic wave receiver 6, one end of shell 9 with a length of 900 mm and a diameter of 70 mm is closed, and the other end is open. Made of iron, the outer surface of the shell 9 is covered with mesh holes 11, and the inner surface of the shell 9 is sprayed with a sound-absorbing coating; the standard test coal pillar 5 with a length of 800mm and a diameter of 66mm is placed in the middle of the shell 9, and the standard test coal pillar 5 is complete The complete coal pillar refers to a coal pillar without large cracks or broken coal pillars. One end of the standard test coal pillar 5 is clampe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com