UV-curable high-functionality resin and preparation method thereof

A high-functionality resin technology, which is applied in the field of UV-curable 8-functionality resin and its preparation, can solve the problems of low hardness of the cured product and low average functionality of UV-curable resin, and achieve the goal of increasing the number and density of double bonds, The effect of high pencil hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

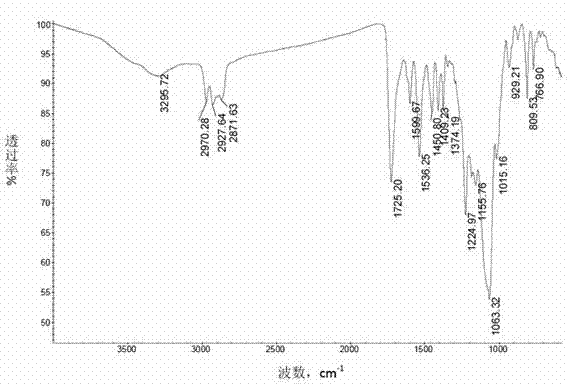

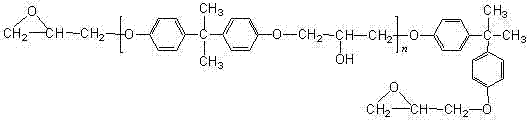

[0054] A UV-curable high-functionality resin, its structural formula is as follows:

[0055] ;

[0056] Wherein: R is the remaining part of the epoxy resin E-51 after removing the epoxy groups at both ends. The epoxy resin E-51 is provided by Wuxi Resin Factory, and its structural formula is as follows:

[0057]

[0058] n is 2-5;

[0059]R1 is the remaining part of 4, 4¢-dicyclohexylmethane diisocyanate after removing the isocyanate groups at both ends.

[0060] The preparation method of the above-mentioned UV-curable high-functionality resin specifically comprises the following steps:

[0061] (1), the preparation of epoxy acrylic resin, the raw materials used for preparation, calculated in parts by weight, its composition and content are as follows:

[0062] Epoxy resin E-51 30 parts

[0063] Acrylic acid 2.5 parts

[0064] Inhibitor 0.02 parts

[0065] Catalyst C 0.02 part;

[0066] Wherein, the structural formula of described epoxy resin E-51 is as follows:

...

Embodiment 2

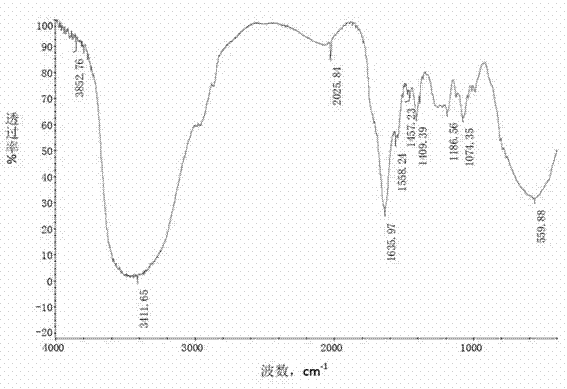

[0096] A UV-curable high-functionality resin, its structural formula is as follows:

[0097]

[0098] Wherein R is the remaining part of the epoxy resin E-51 after removing the epoxy groups at both ends. The epoxy resin E-51 is provided by Wuxi Resin Factory, and its structural formula is as follows:

[0099]

[0100] n is 2-5;

[0101] R1 is the remaining part of isophorone diisocyanate after removing the isocyanate groups at both ends. The structural formula of isophorone diisocyanate is as follows:

[0102] .

[0103] The preparation method of above-mentioned a kind of UV curable high-functionality resin specifically comprises the following steps:

[0104] (1), the preparation of epoxy acrylic resin, the raw materials used for preparation, calculated in parts by weight, its composition and content are as follows:

[0105] Epoxy resin E-51 60 parts

[0106] Acrylic 5 parts

[0107] Inhibitor 1.0 parts

[0108] Catalyst C 1.0 parts;

[0109] Wherein, the struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com