Window film core functional layer and preparation method thereof

A core function and window film technology, applied in the field of optical, can solve problems such as complexity of production technology, and achieve the effect of improving market competitiveness, enriching product lines, and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

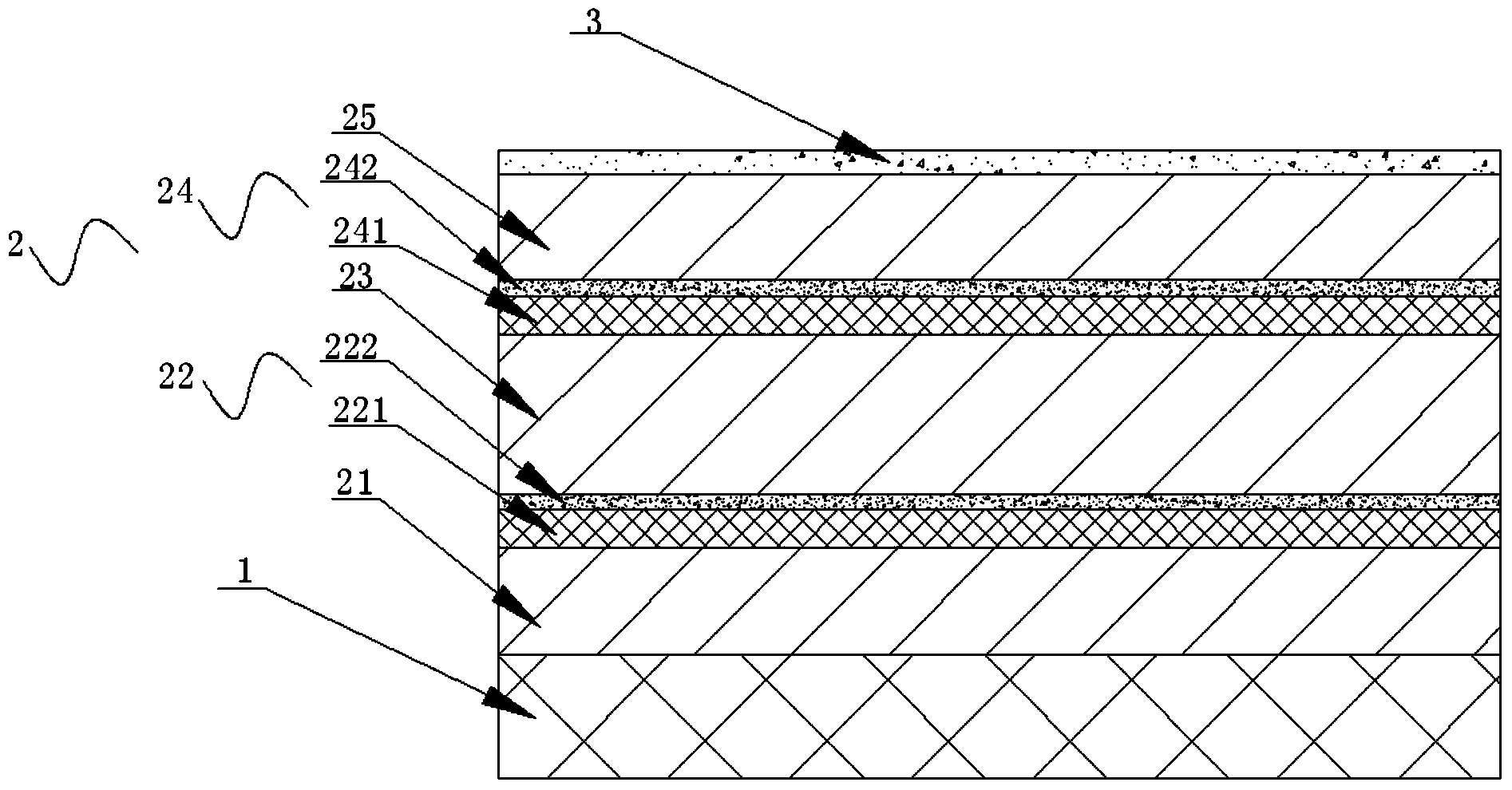

[0039] like figure 1 As shown, a core functional layer of a window film includes a PET base film 1 and a magnetron sputtering layer 2 disposed on the PET base film 1, and the magnetron sputtering layer 2 includes sequentially deposited from bottom to top The above-mentioned first transparent oxide layer 21 , first composite metal layer 22 , second transparent oxide layer 23 , second composite metal layer 24 , third transparent oxide layer 25 and outer sealing layer 3 . The material of the first transparent oxide layer 21 , the second transparent oxide layer 23 and the third transparent oxide layer 25 is one of metal oxide, ITO or AZO.

[0040] Moreover, the first composite metal layer 22 includes a bottom-up first Ag layer 221 and a first seal metal layer 222; the second composite metal layer 24 includes a bottom-up second Ag layer 241 and The second sealing metal layer 242 . The materials of the first Ag layer 221 and the second Ag layer 241 are both Ag, and the materials o...

Embodiment 2

[0057] The difference between this embodiment and the first embodiment is that the power of the first chamber is controlled to be 30 kW, so that the deposition thickness of the first transparent oxide layer 21 is 40 nm.

[0058] Control the power of the second chamber to be 15kW, so that the deposition thickness of the first composite metal layer 22 is 20nm, wherein the deposition thickness of the first Ag layer 221 is 15nm, and the first sealing layer metal layer 222 and The deposition thickness is 5nm.

[0059] The power of the third chamber is controlled to be 30kW, so that the deposition thickness of the second transparent oxide layer 23 is 60nm.

[0060] Control the power supply of the fourth chamber to be 15kW, so that the deposition thickness of the second composite metal layer 24 is 20nm, wherein the deposition thickness of the second Ag layer 221 is 15nm, and the deposition thickness of the second sealing layer metal layer 222 is 5nm .

[0061] Control the power sup...

Embodiment 3

[0065]The difference between this embodiment and the first embodiment is that the power of the first chamber is controlled to be 25kW, so that the deposition thickness of the first transparent oxide layer 21 is 35nm.

[0066] Control the power of the second chamber to be 10kW, so that the deposition thickness of the first composite metal layer 22 is 16.5nm, wherein the deposition thickness of the first Ag layer 221 is 12.5nm, and the deposition thickness of the first composite metal layer 22 is 12.5nm. The deposition thickness of the layer metal layer 222 is 4 nm.

[0067] Control the power supply of the third chamber to 25kW, so that the deposition thickness of the second transparent oxide layer 23 is 52.5nm.

[0068] Control the power of the fourth chamber to be 15kW, so that the deposition thickness of the second composite metal layer 24 is 16.5nm, wherein the deposition thickness of the second Ag layer 221 is 12.5nm, and the deposition thickness of the second sealing layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com