Manufacturing device of enhanced metal spiral corrugated pipe

A spiral bellows and manufacturing equipment technology, applied in the field of manufacturing equipment for the production of reinforced metal spiral bellows, can solve the problems of spending a lot of time adjusting the angle, affecting the accuracy of the support roller, and taking a long time to replace, so as to improve product quality , Improve the smoothness of the inner wall, and have good equipment versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

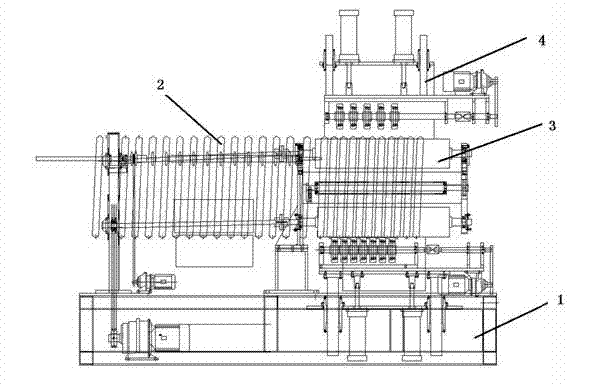

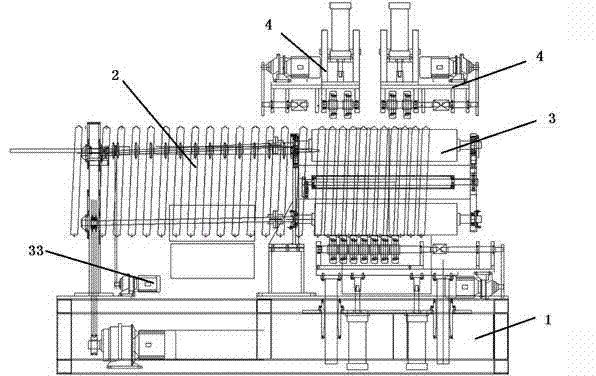

[0032] Such as figure 1 , 2 The manufacturing equipment for a reinforced metal spiral corrugated pipe shown is provided on the base 1 along the pipe advancing direction in sequence: a metal reinforcing rib forming push unit 2, a threaded pipe wall forming unit 3, and a rolling unit 4; Before the metal reinforcing rib is sent into the threaded pipe wall forming unit 3, a device for heating the metal reinforcing rib is also provided. The metal reinforcing rib forming and pushing unit 2 includes: a metal strip bending forming mechanism and a forming reinforcing rib pushing mechanism.

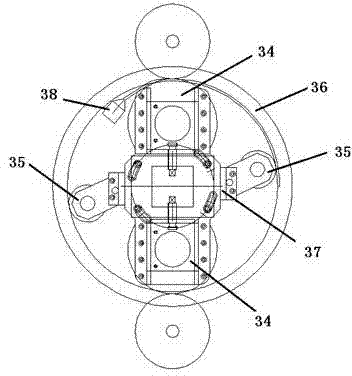

[0033] The metal reinforcing rib forming unit bends the metal strip into the required shape through the metal strip bending forming mechanism, and then sends the metal reinforcing rib into the threaded pipe wall forming unit 3 through the pushing mechanism of the formed reinforcing rib; the threaded pipe wall forming unit 3 The main support roller driving mechanism 33 drives the main support roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com