Full-automatic series core-making center of inorganic precoated sand

A coated sand, fully automatic technology, applied in the field of core shooting system, can solve problems such as sand bonding, core shooting machine without cooling system, hot air blowing system cannot be completed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

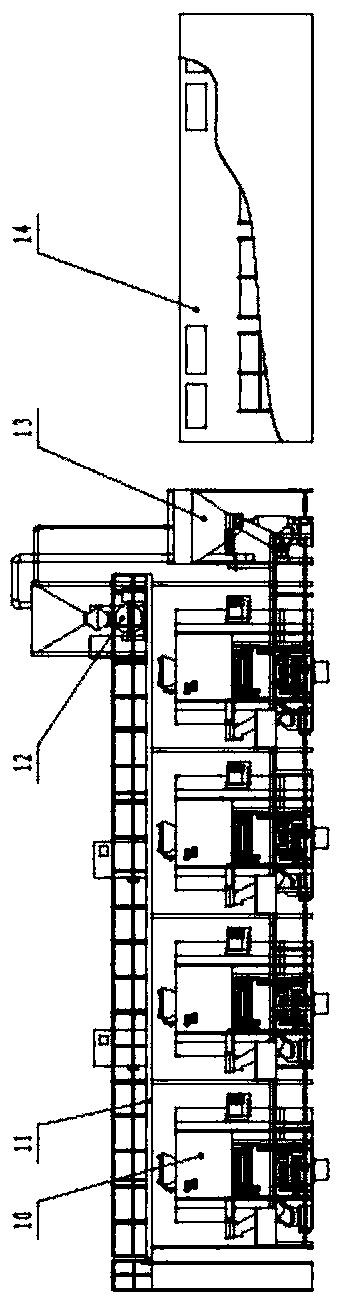

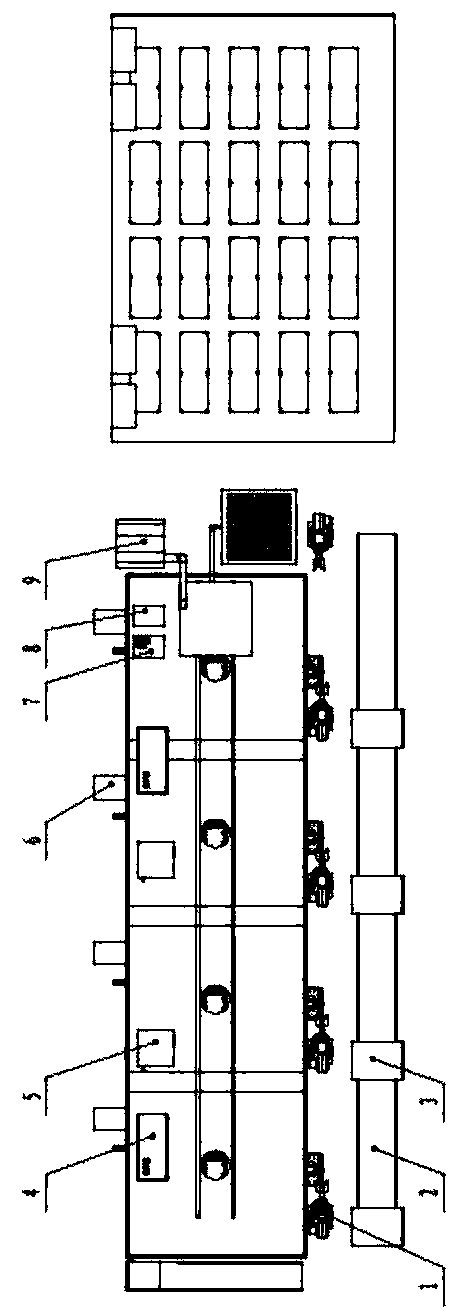

[0017] The reference signs in the drawings of the specification include: 1. Coring robot; 2. Sand core flow channel; 3. Fixture exchange tray; 4. Hot air system; 5. Cooling system; 6. Power distribution cabinet of core shooter; 7. Power distribution cabinet for sand mixing system; 8. Dosing storage box; 9. Bag type dust collector; 10. Core shooter; 11. Upper working platform; 12. Ball sand mixer; 13. Sand blowing device; 14 , Sand core constant temperature and humidity storage.

[0018] The embodiment is basically as figure 1 , 2 As shown: the inorganic coated sand automatic series core making center of the present invention is composed of four core shooting machines 10, and has a newly designed water-cooled core shooting system, including sand storage buckets, sand shooting cylinders, sand shooting buckets, and sand shooting boards and other equipment. A flow channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com