Preparation method of graphene and manganous manganic oxide composite electrode material

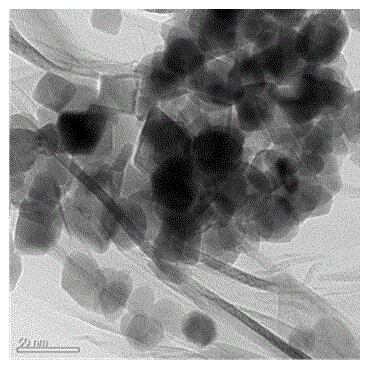

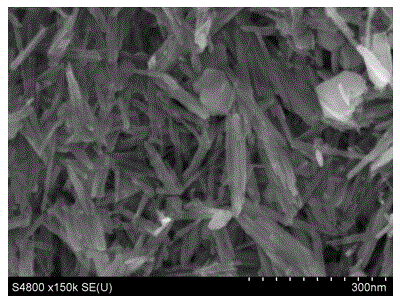

A technology of trimanganese tetraoxide and composite electrodes, which is applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of difficult industrialization, harsh reaction conditions, and low specific capacitance, and achieve the effect of simple and convenient reaction steps and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of preparation method of graphene / manganese tetraoxide composite electrode material, concrete steps are as follows:

[0026] A preparation method of a graphene / trimanganese tetraoxide composite electrode material, specifically comprising the steps of:

[0027] (1) First, mix 0.14g of graphene oxide and 2.8g of manganese chloride tetrahydrate at a mass ratio of 1:20 and add them to 200ml of isopropanol solution, ultrasonically disperse them and place them in a water bath at 83°C , and then add 20ml of potassium permanganate (1.51g) aqueous solution with a concentration of 75.5g / L. After the addition is completed, the speed is controlled at 1000r / min, and the temperature is 83°C for 30min. The obtained reaction solution is suction filtered, and the obtained filter cake Washing with distilled water until the effluent is neutral, and then drying at a controlled temperature of 50-65°C to obtain a graphene oxide / acicular manganese dioxide precursor;

[0028] The add-o...

Embodiment 2

[0037] A preparation method of a graphene / trimanganese tetraoxide composite electrode material, specifically comprising the steps of:

[0038] (1), the preparation of graphene oxide / acicular manganese dioxide precursor is the same as step (1) in Example 1;

[0039] (2) Take 0.3g of the graphene oxide / manganese dioxide precursor obtained in step (1) and ultrasonically disperse it in 300ml of distilled water to obtain an aqueous solution of the graphene oxide / manganese dioxide precursor. Add 1.5g reducing agent to the manganese precursor aqueous solution, then let it stand for 15 hours, then carry out the reduction reaction at a temperature of 83°C for 2 hours, suction filter the obtained reaction solution, wash the obtained filter cake repeatedly with distilled water until the effluent is neutral, and finally Control the temperature at 50°C-65°C for drying to obtain the graphene / trimanganese tetraoxide composite electrode material;

[0040] In the described graphene oxide / mang...

Embodiment 3

[0044] A preparation method of a graphene / trimanganese tetraoxide composite electrode material, specifically comprising the steps of:

[0045] (1), the preparation of graphene oxide / acicular manganese dioxide precursor is the same as step (1) in Example 1;

[0046] (2) Take 0.3g of the graphene oxide / manganese dioxide precursor obtained in step (1) and ultrasonically disperse it in 300ml of distilled water to obtain an aqueous solution of the graphene oxide / manganese dioxide precursor. Add 2.5g reducing agent to the manganese precursor aqueous solution, then let it stand for 15h, and then carry out the reduction reaction at 83°C for 2h, the obtained reaction liquid is suction filtered, and the obtained filter cake is repeatedly washed with distilled water until the effluent is neutral, and finally Control the temperature at 50°C-65°C for drying to obtain the graphene / trimanganese tetraoxide composite electrode material;

[0047] In the described graphene oxide / manganese dioxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com