Comprehensive forecast and iterative learning control method based on 2D theory

A technology of iterative learning control and comprehensive prediction, applied in the direction of program control, comprehensive factory control, comprehensive factory control, etc., can solve problems such as inaccurate intermittent processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The comprehensive predictive iterative learning control method based on 2D theory proposed by the present invention comprises the following steps:

[0050] 1) Combined with the actual production process, set up a batch production data collection and storage link, which can use the existing industrial control computer, PLC and other equipment of the production enterprise;

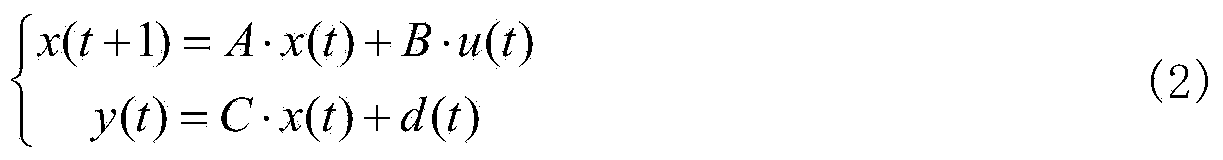

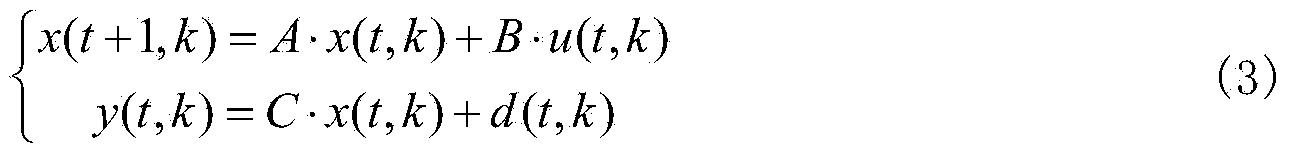

[0051] 2) According to the past production process data in the collected production history database, after data preprocessing, adopt an appropriate method to establish a simple mathematical model of the production process;

[0052] 3) The data acquisition link collects the input and output data of product processing in the industrial production line, and calculates the tracking error curve according to the target tracking trajectory;

[0053] 4) According to the tracking error obtained in step 3), a new real-time control quantity is calculated by using an integrated predictive iterative learning cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com