General-purpose optical fiber connector

A fiber optic connector, a general-purpose technology, applied in the field of general-purpose fiber optic connectors, can solve problems such as damage to the quality of connection points, waste of connectors, waste of materials, etc., to improve production efficiency, enhance tensile performance, and improve resources. The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

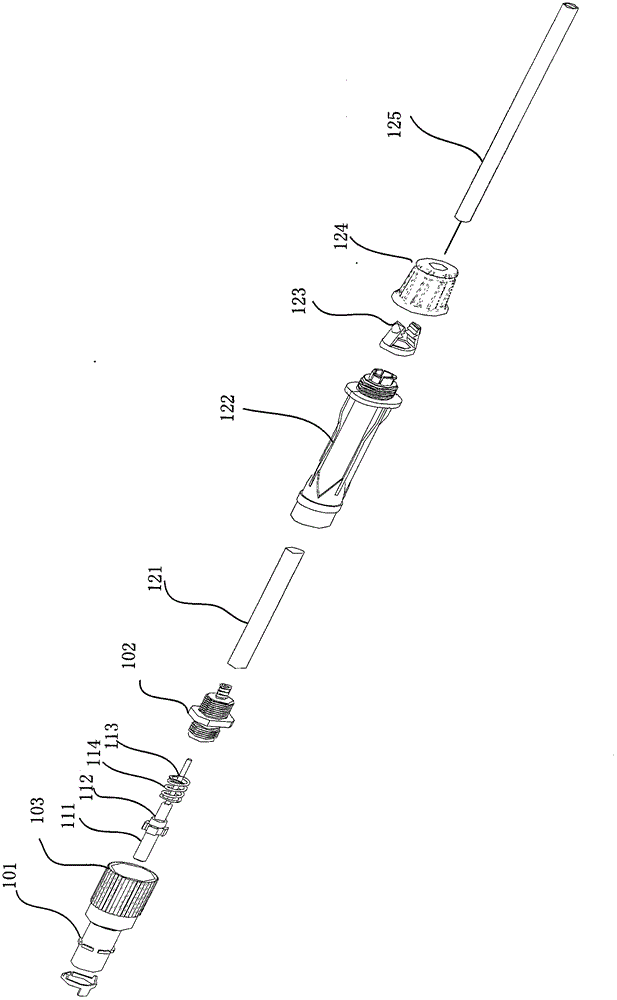

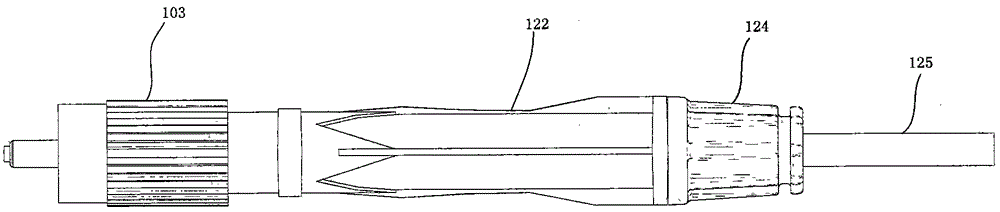

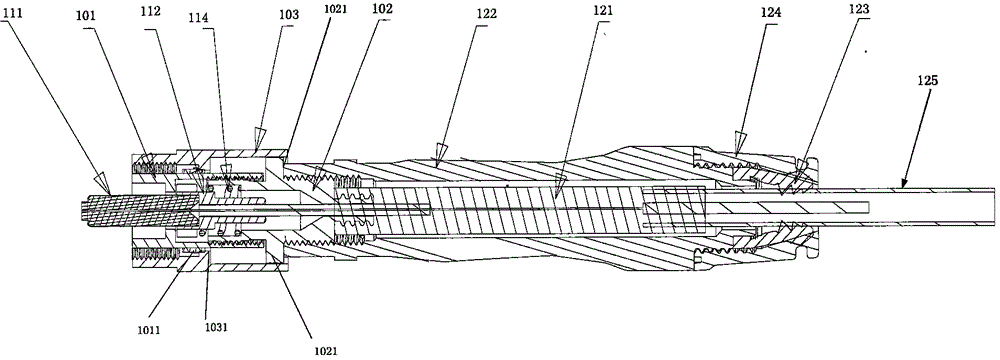

[0032] The general optical fiber connector provided by the embodiment of the present invention will be further described in detail below with reference to the accompanying drawings. However, the embodiments of the present invention and the components shown in the drawings are only preferred embodiments of the present invention, and cannot replace the technical idea of the present invention. The terms and words used in the description and the claims are only for explaining the technical solution of the present invention in the best way, and should not be construed as limiting the technical idea of the present invention.

[0033] The core idea of the present invention is to provide a general-purpose optical fiber connector, which includes a heat-melt connector assembly, a heat-shrinkable sleeve, and a heat-shrinkable sleeve protective shell, wherein the heat-melt connector assembly is further It includes the main body of the hot-melt head, the ceramic ferrule, the ceramic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com