Automatic pipeline-type pulp density detection system and method

A technology for automatic detection of pulp concentration, applied in measuring devices, specific gravity measurement, instruments, etc., can solve the problem that detection accuracy is affected by pulp composition, viscosity, air bubbles, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

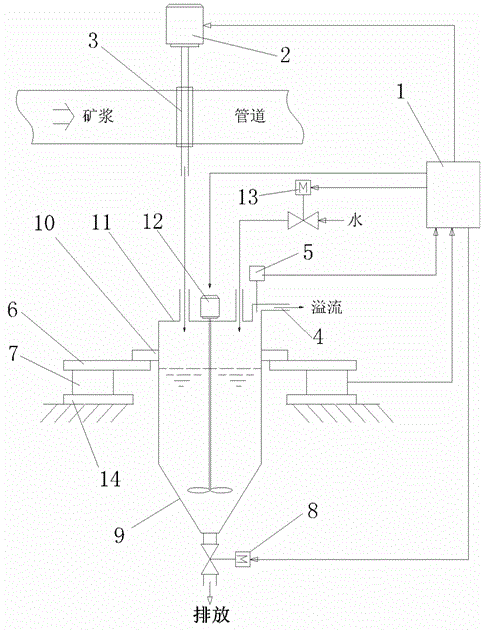

[0028] Embodiment 1: as figure 1 As shown, a pipeline type automatic detection system for pulp concentration is composed of automatic pulp sampling device, weighing device and measurement and control device; the automatic sampling device is installed on the pulp pipeline, the weighing device is installed under the automatic sampling device, and the measurement and control device The measurement and control host 1 is installed next to the automatic sampling device or other places that are convenient for observation and operation, and the remaining components of the measurement and control device are installed on site;

[0029] The automatic sampling device includes an actuator 2 and a sampling valve 3; wherein the sampling valve 3 is installed on the pulp pipeline, the actuator 2 is installed above the sampling valve 3, and the output shaft of the actuator 2 is connected to the shaft of the sampling valve 3;

[0030] The weighing device comprises an overflow pipe 4, a cantileve...

Embodiment 2

[0043] Embodiment 2: as figure 1 As shown, a pipeline-type pulp concentration automatic detection system and method, the specific design is as follows:

[0044] It is used in the slurry pipeline transported by the sand pump, the slurry is chalcopyrite, and the ore density is 3.2g / cm 3 , the density of water is 1.0 g / cm 3 , the pulp fineness is 80% (-200 mesh), the pulp pressure is 0.6MPa, the pipe diameter is DN80, and the concentration measurement range is 0-80%.

[0045] Sampling valve 3 has a specification of DN80 and is installed on the slurry pipeline. The model of actuator 2 is UNIC-10, which is installed above sampling valve 3, and its output shaft is connected to the shaft of sampling valve 3 through a shaft connector;

[0046] The material of the slurry container 9 is 316L stainless steel, the upper part is cylindrical (the specification is Φ80X100), the lower part is conical, the outlet diameter is Φ20, the lower part outlet is connected with the slurry discharge s...

Embodiment 3

[0054] Embodiment 3: as figure 1 As shown, a pipeline-type pulp concentration automatic detection system and method, the specific design is as follows:

[0055] Applied in self-flowing slurry pipeline, the slurry is magnetite, and the ore density is 2.9g / cm 3 , the density of water is 1.02 g / cm 3 , the pulp fineness is 70% (-200 mesh), the pipe diameter is DN125, and the concentration measurement range is 0-70%.

[0056] Sampling valve 3 has a specification of DN125 and is installed on the slurry pipeline. The model of actuator 2 is UNIC-20 and is installed above sampling valve 3. Its output shaft is connected to the shaft of sampling valve 3 through a shaft connector;

[0057] The pulp container 9 is made of 314 stainless steel, the upper part is cylindrical (with a specification of Φ100X120), the lower part is conical with a diameter of Φ25, the lower outlet is connected to the slurry discharge solenoid valve 8, and the upper part of the pulp container 9 is covered with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com