Method for display dentrite morphology of gear steel continuous-casting billet

A display method and continuous casting slab technology, which is applied in the display field of gear steel continuous casting slab dendrite morphology, can solve the problems of low success rate, temperature sensitivity, long time, etc., and achieve fast erosion, easy operation, and erosion The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

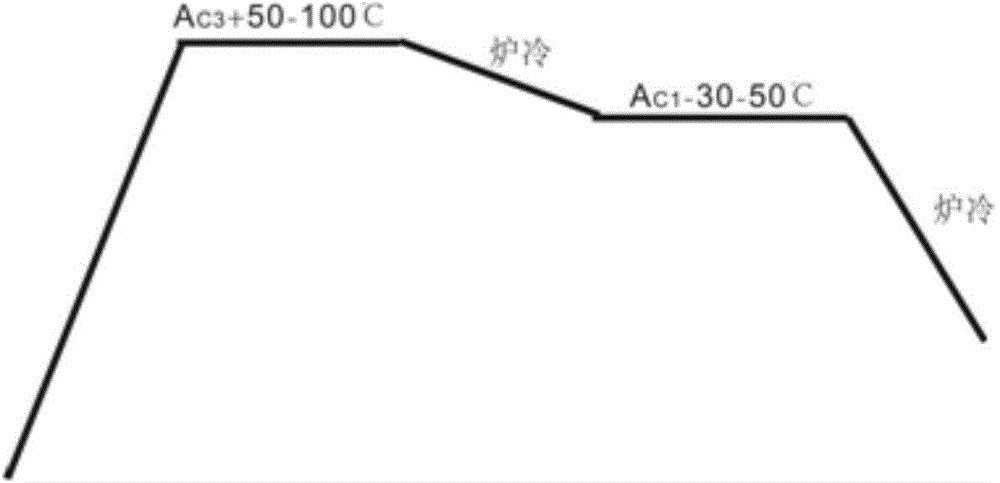

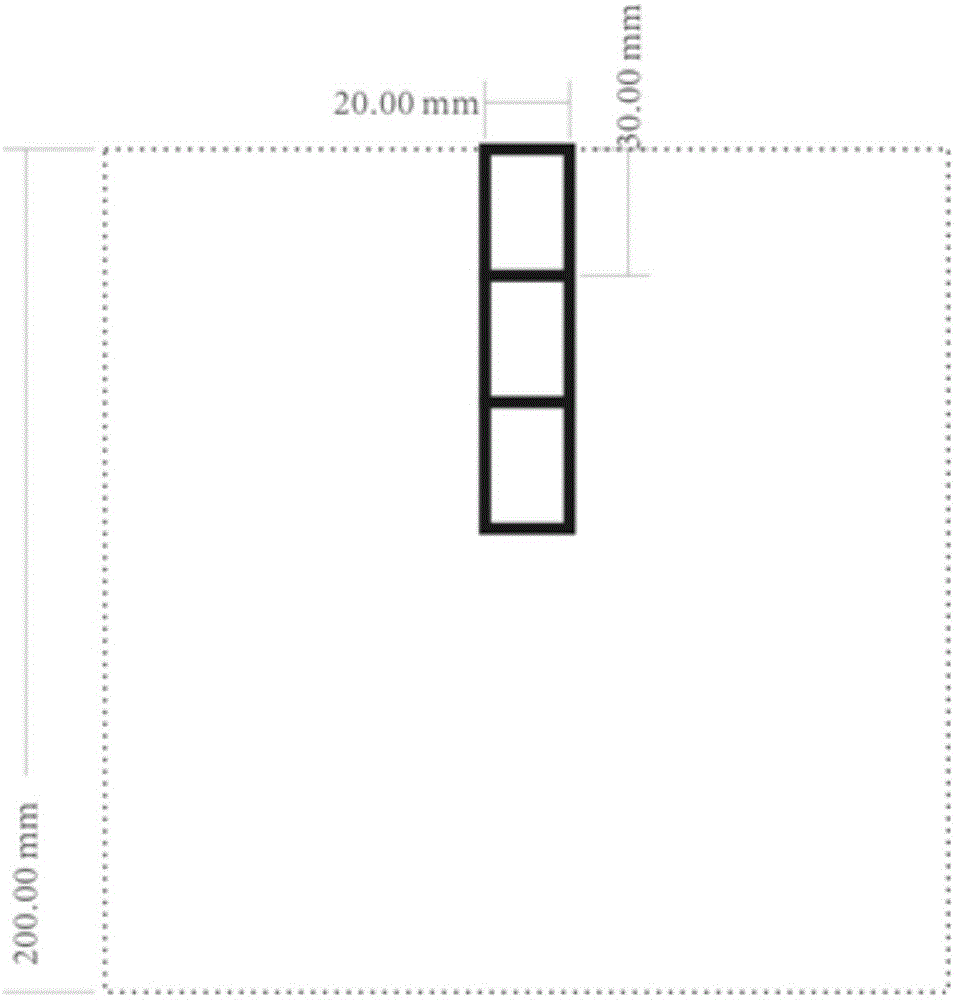

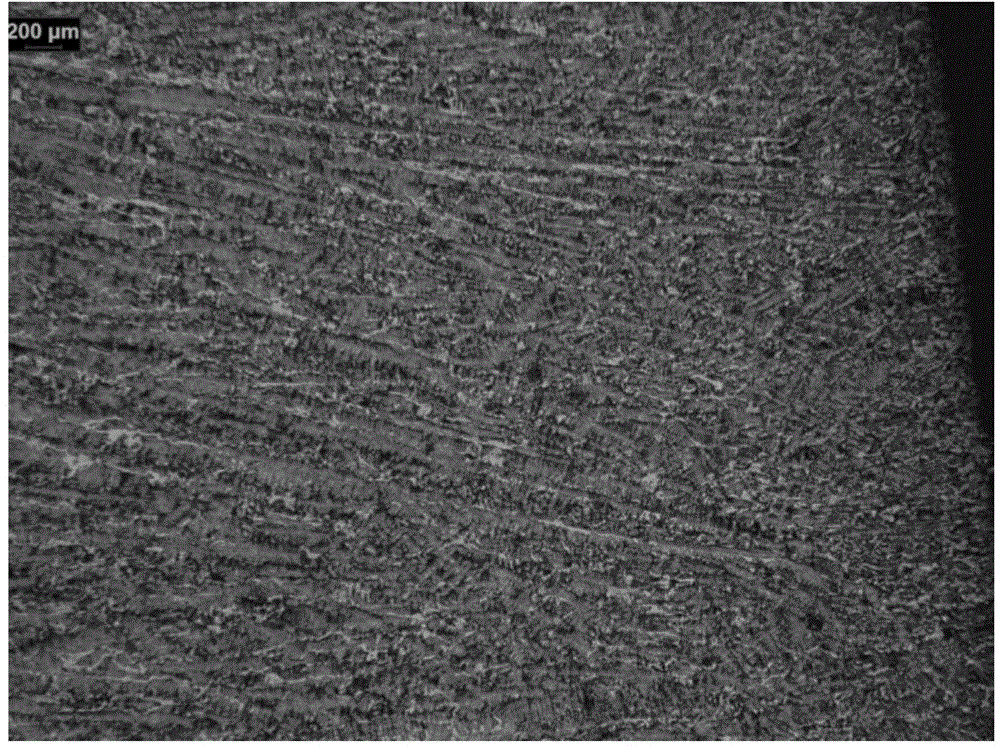

[0031] Dendritic erosion in continuously cast slabs for gear steel 20CrMnTiH. The sample is taken from the 20CrMnTiH continuous casting slab with a size of 200mm×200mm, and the sample is cut as figure 2 Dimensions shown, heat treated. The heat treatment process is as follows: the sample is heated to 930°C for 30 minutes, cooled to 680°C for 2 hours in the furnace, and then cooled to room temperature with the furnace. After heat treatment, the sample is milled off by 2 mm to avoid decarburization on the observation surface. After grinding and polishing, it was etched with 4% nitric acid alcohol. In order to compare with this method, this embodiment also uses picric acid series etchant to show its dendrite morphology. The morphology of dendrites at the edge, 1 / 4, and center of the slabs eroded by the two methods were observed by optical microscope.

[0032] image 3 The dendrite morphology of the continuous casting slab surface after picric acid attack is given. It can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com