Dual-purpose cabin for dynamic pressure calibration of optical pressure sensitive coatings

A dynamic pressure and pressure technology, applied in the measurement of fluid pressure, measuring devices, instruments, etc., can solve the problems that the dynamic pressure calibration chamber cannot complete the calibration, and the dynamic pressure calibration has not made breakthroughs, etc., and achieves a simple structure, easy processing, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

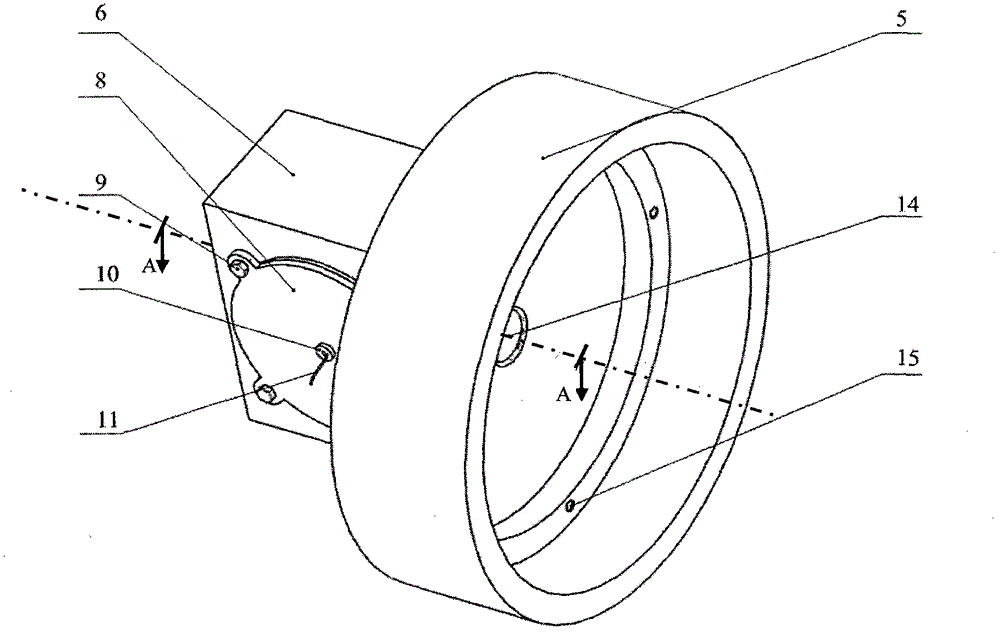

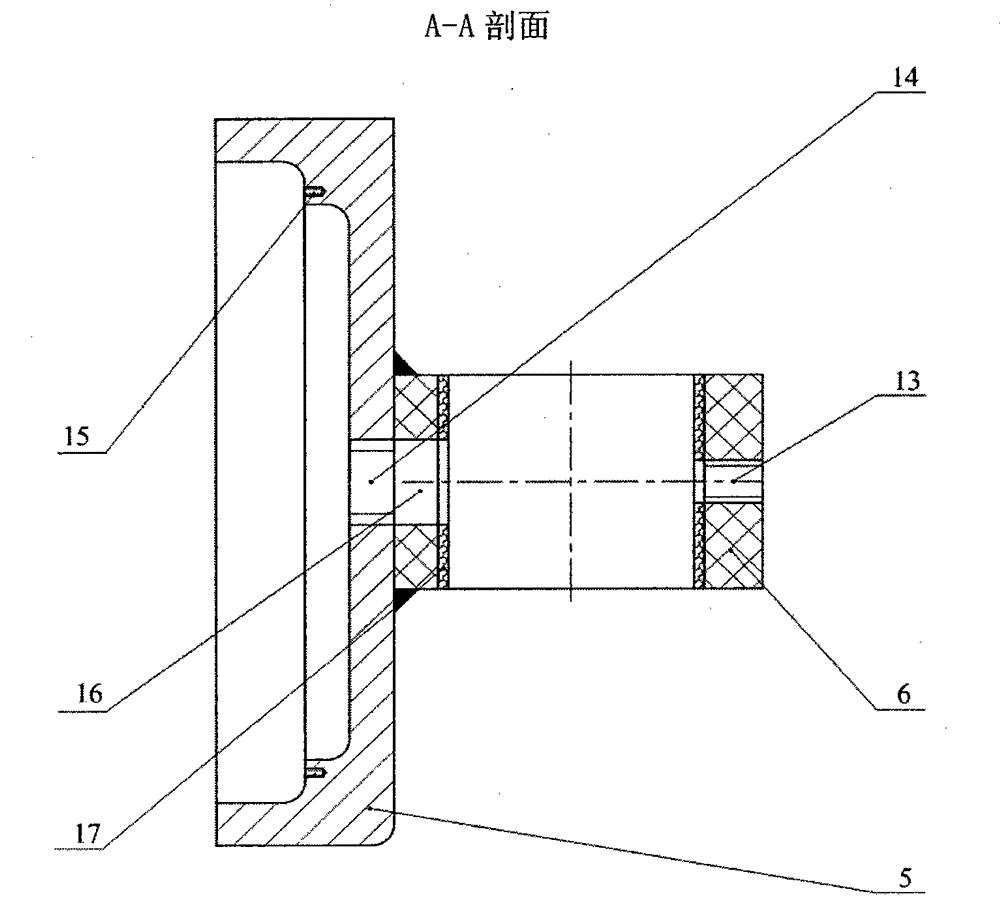

[0019] The calibration chamber of the present invention is mainly used for dynamic pressure calibration of optical pressure-sensitive coatings, and can be used in two modes, and the installation of the main body of the calibration chamber is the same in these two modes. After manufacturing the parts of this calibration chamber according to the drawings, install and seal according to the following steps:

[0020] 1. As attached figure 1 Shown, sound-absorbing material (can be with sponge) is pasted on the interior avoiding of square experiment cabin 6, the hole on the sound-absorbing material is concentric with through hole 16 and air source hole 13, guarantees not blocking the air-flow of outside in the cabin.

[0021] 2. Place the dynamic pressure sensor 11 in the protective cover 10, pay attention that the pressure sensing part of the sensor must be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com