Phase-change heat exchange pipe bundle with optimized structure and production process of phase-change heat exchange pipe bundle

A technology of phase-change heat transfer and optimized structure, which is applied to indirect heat exchangers, household heating, heating methods, etc., can solve the problems of low installation efficiency and obstacles to the large-scale promotion of air-source heat pump direct expansion heat transfer technology, and achieve Improvement of construction speed, improvement of energy utilization rate, and improvement of energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

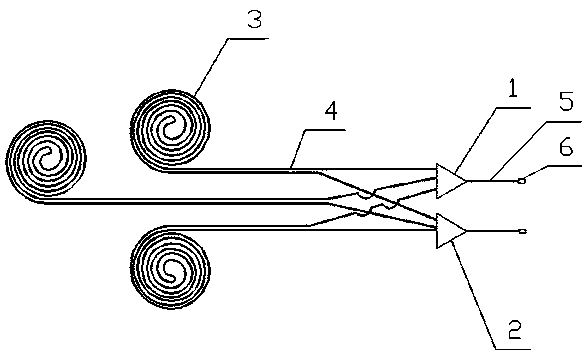

[0026] Embodiment 1: as figure 1 As shown, a phase-change heat tube bundle with an optimized structure is used to extract the phase-change heat of compressed steam for phase-change heat, including two capillary tubes 4 , a gas distributor 1 and a liquid return head 2 . Each capillary is wound into a capillary disk 3 .

[0027] The capillary coil is formed by a single capillary 4 having a bend 9 in the middle of the length direction, and then winding side by side after bending. There are two joints left on each capillary disc. The joints at both ends of the capillary 4 are respectively welded on the gas distributor 1 and the liquid return head 2. The connected liquid return joint 5', the ends of the air inlet joint 5 and the liquid return joint 5' are all provided with a nanocap 6 for connection.

[0028] How to use: After welding multiple capillaries in the tube bundle in the ZL2012202753539 patent technology to the gas distributor or liquid return head, the overall processi...

Embodiment 2

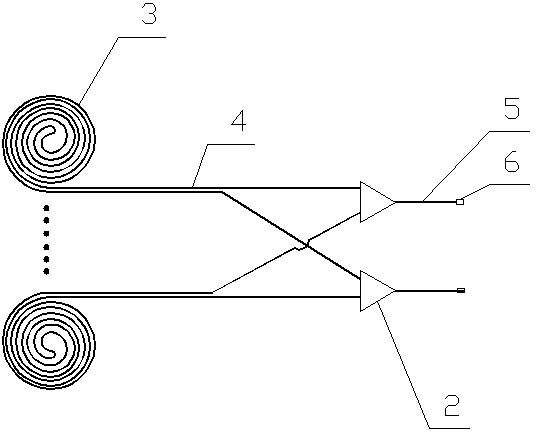

[0029] Embodiment 2: as figure 2 As shown, a phase-change heat pipe bundle with an optimized structure includes three capillaries 4 , a gas distribution head 1 and a liquid return head 2 . After bending, at least five helical concentric circles with different diameters are wound side by side.

[0030] Other structures are the same as in Embodiment 1.

Embodiment 3

[0031] Embodiment 3: as image 3 As shown, a phase-change heat pipe bundle with an optimized structure includes a plurality of capillaries 4 , a gas distribution head 1 and a liquid return head 2 . The inner diameter of the capillary is 1.0mm~6mm, and the length is 3m~46m. The number of capillaries in each group of tube bundles is 4-50.

[0032] Other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com