Outer spiral steel cylinder of evaporator for ice cream machine and machining method thereof

A technology of ice cream machine and evaporator, applied in evaporator/condenser, heat exchanger shell, refrigerator, etc., can solve the problems of low production efficiency, troublesome process, laborious processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

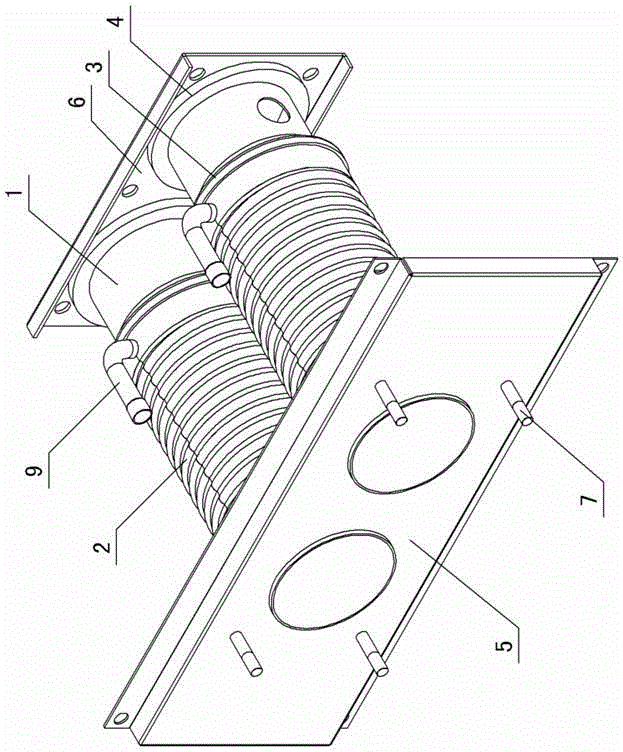

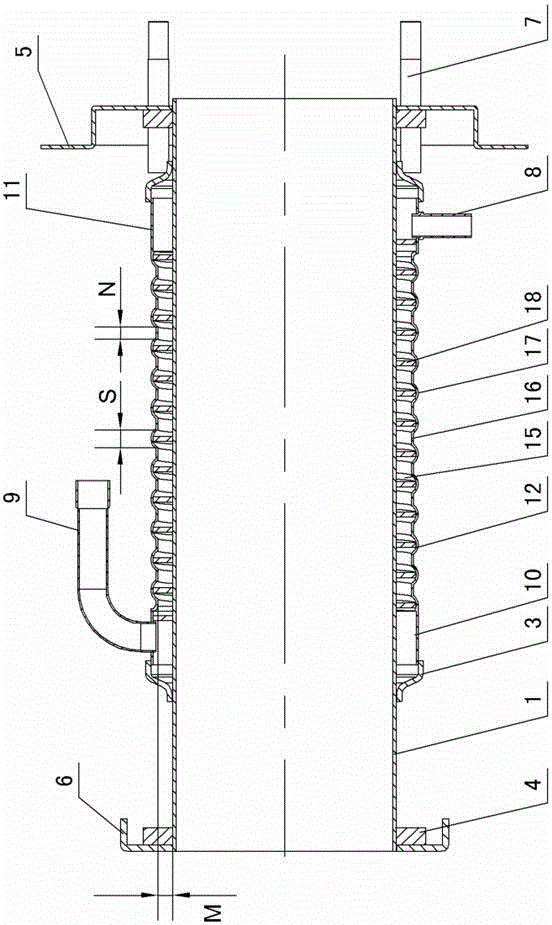

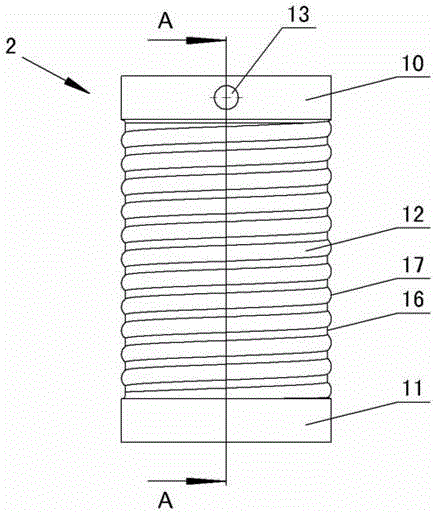

[0021] The invention relates to a spiral outer steel cylinder of an ice cream machine evaporator and a processing method thereof, such as figure 1 — Figure 5 As shown, the inner steel cylinder 1 including the evaporator, the spiral sheet 18 sleeved on the outer wall of the inner steel cylinder, the outer steel cylinder 2 sleeved on the outer wall of the spiral sheet, and the outer steel cylinder method is connected between the two ends of the outer steel cylinder and the inner steel cylinder Lan 3, the two ends of the inner steel cylinder 1 are connected to the inner steel cylinder flange 4, the front panel 5 and the rear connecting plate 6, the screw rod 7 is arranged on the front panel, and the refrigerant inlet joint 8 and the refrigerant outlet are respectively connected to the outer steel cylinder 2. The material joint 9 is characterized in that: the outer steel cylinder 2 includes a left connecting section 10, a right connecting section 11 and a spiral surrounding secti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com