A method for saving energy in a liquefied petroleum gas station

A technology of liquefied petroleum gas and petroleum gas, which is applied in the direction of combustion method, heating method, liquid fuel supply/distribution, etc., can solve the problems of low conversion efficiency of cooling capacity, large engineering quantity, long distance of cold water transportation, etc., and achieve the utilization of cooling capacity High efficiency, low cost of use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

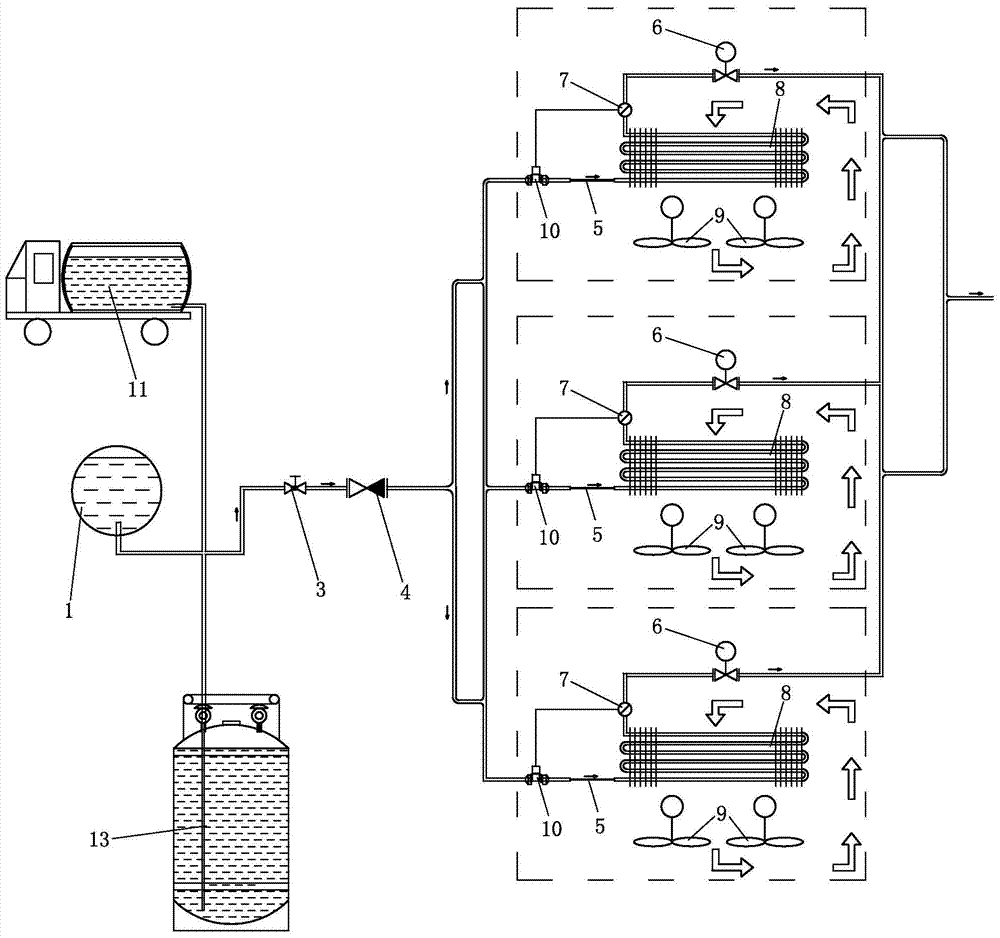

[0017] Such as figure 1 Shown is the process flow diagram of the energy-saving method of the liquefied petroleum gas station of the present invention, the cooling capacity utilization method of the present invention is as follows: the liquefied petroleum gas is discharged from the normal temperature liquid storage tank 1 or the tank car 11 or the liquefied petroleum gas cylinder of the liquefied petroleum gas station 13 (the pressure is 0.4-0.6MPa, so no pump is needed) passes through the stop valve 3 and the check valve 4, and then is transported to the capillary 5 through pipelines, and the liquefied petroleum gas flows out from the capillary 5 and enters the coil 8 on the top of the room for liquefaction Petroleum gas can be turned into gaseous petroleum gas without any external energy in the coil 8. During the process of changing from liquid to gas, petroleum gas absorbs heat to lower the temperature of the coil 8, and the temperature of the air around the outer wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com