Persimmon vinegar making method

A production method and technology of persimmon vinegar are applied in the field of production of persimmon vinegar, which can solve the problems of low utilization rate of persimmon nutrients, unsuitability for large-scale production, and poor taste of finished vinegar, so as to improve juice yield, protect the environment, clarify good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

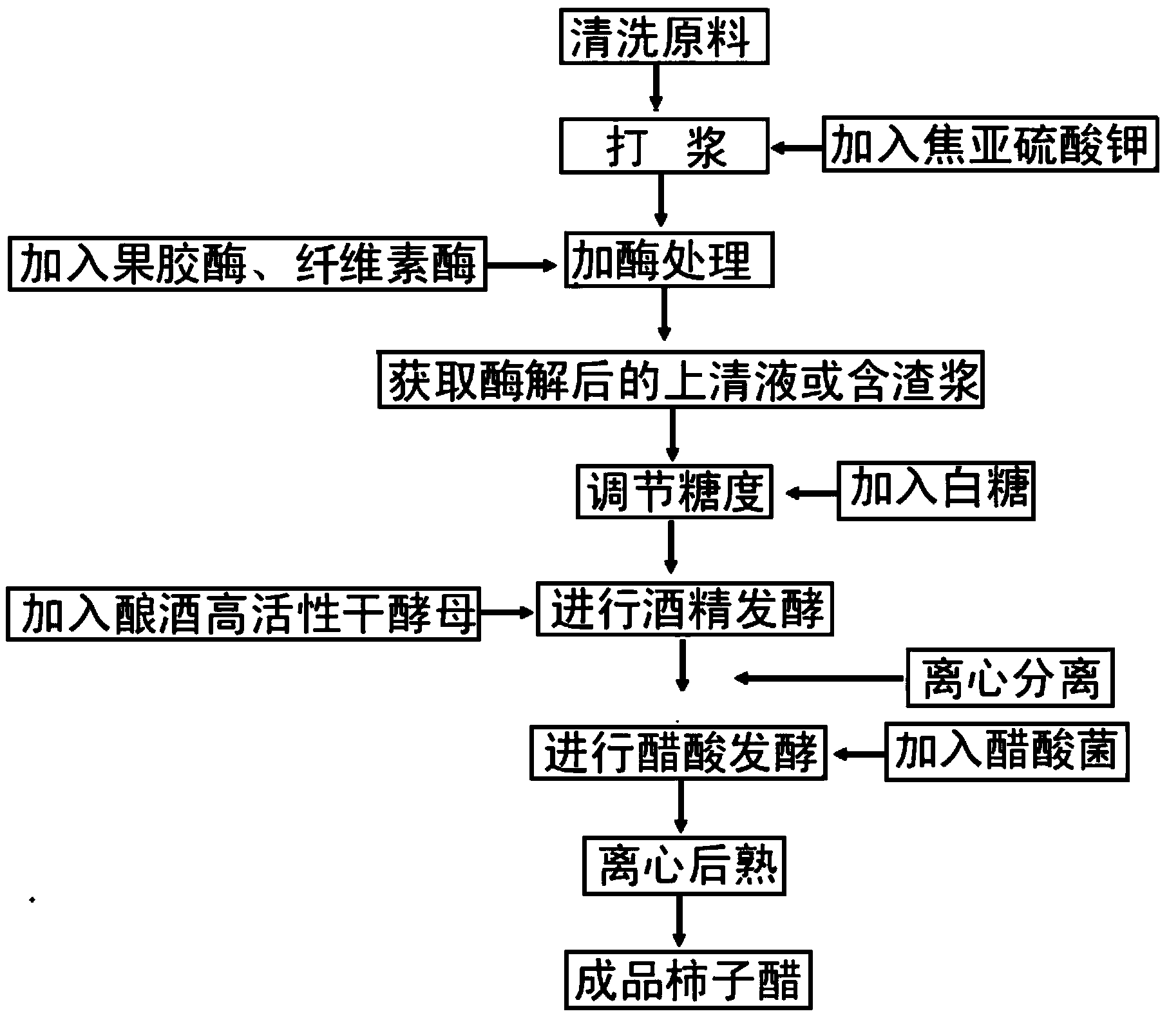

Image

Examples

Embodiment 1

[0027] Embodiment 1 utilizes supernatant liquid fermentation to make persimmon vinegar, and concrete steps are as follows:

[0028] (1) Take 2 kg of persimmon skin and wash it;

[0029] (2) Add sterile water 4kg and 0.6g potassium metabisulfite for beating;

[0030] (3) Add 9g of pectinase and 2.4g of cellulase to treat the pulp, and incubate at 50°C for 60min;

[0031] (4) Get the supernatant of persimmon pulp that has been treated with pectinase and cellulase and place it in a fermenter;

[0032] (5) adjust the final sugar content to 15% with white sugar;

[0033] (6) Add 0.02% Saccharomyces cerevisiae highly active dry yeast, carry out alcoholic fermentation at 30°C for 7 days, measure the amount of residual sugar every day, the residual sugar is reduced to 8.6%, and no longer drops, and the alcoholic fermentation ends at this time;

[0034] (7) centrifuge to remove waste residue;

[0035] (8) Add 0.05% acetic acid bacteria, control the temperature at 30°C and carry out...

Embodiment 2

[0038] Embodiment 2 supernatant fermentation makes persimmon vinegar, concrete steps are as follows:

[0039] (1) Weigh 2 kg of persimmon skin and wash it,

[0040] (2) Add sterile water 4kg and 0.6g potassium metabisulfite for beating;

[0041] (3) Add 9g of pectinase and 2.4g of cellulase to treat the pulp, and incubate at 50°C for 60min;

[0042] (4) Get the supernatant of persimmon pulp that has been treated with pectinase and cellulase and place it in a fermenter;

[0043](5) adjust the final sugar content to 12% with white sugar;

[0044] (6) Add 0.02% Saccharomyces cerevisiae highly active dry yeast, carry out alcoholic fermentation at 30°C for 6 days, measure the amount of residual sugar every day, the residual sugar is reduced to 6%, and no longer drops, and the alcoholic fermentation ends at this time;

[0045] (7) centrifuge to remove waste residue;

[0046] (8) Add 0.05% acetic acid bacteria, control the temperature at 30°C and carry out acetic acid fermentatio...

Embodiment 3

[0049] Embodiment 3 directly contains slag fermentation and makes persimmon vinegar, and concrete steps are as follows:

[0050] (1) Take 2 kg of persimmon skin and wash it;

[0051] (2) Add sterile water 4kg and 0.6g potassium metabisulfite for beating;

[0052] (3) Add 9g of pectinase and 2.4g of cellulase to treat the pulp, and incubate at 50°C for 60min;

[0053] (4) get the persimmon skin containing slag slurry that has been processed through pectinase and cellulase and place it in a fermenter;

[0054] (5) adjust the final sugar content to 9% with white sugar;

[0055] (6) Add 0.02% Saccharomyces cerevisiae highly active dry yeast, carry out alcoholic fermentation at 30°C for 5 days, measure the amount of residual sugar every day, the residual sugar is reduced to 4%, and no longer decreases, and the alcoholic fermentation ends at this time;

[0056] (7) centrifuge to remove waste residue;

[0057] (8) Add 0.05% acetic acid bacteria, control the temperature at 30°C an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com