Health care reed beer and production process thereof

A production process, reed technology, applied in reed health care beer and its production process, in the field of reed beer, can solve the problems of affecting beer flavor, reed leaf residue, affecting wort filtration effect, etc., to achieve simple and practical overall process, slightly darker color , the effect of high nutritional and health value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

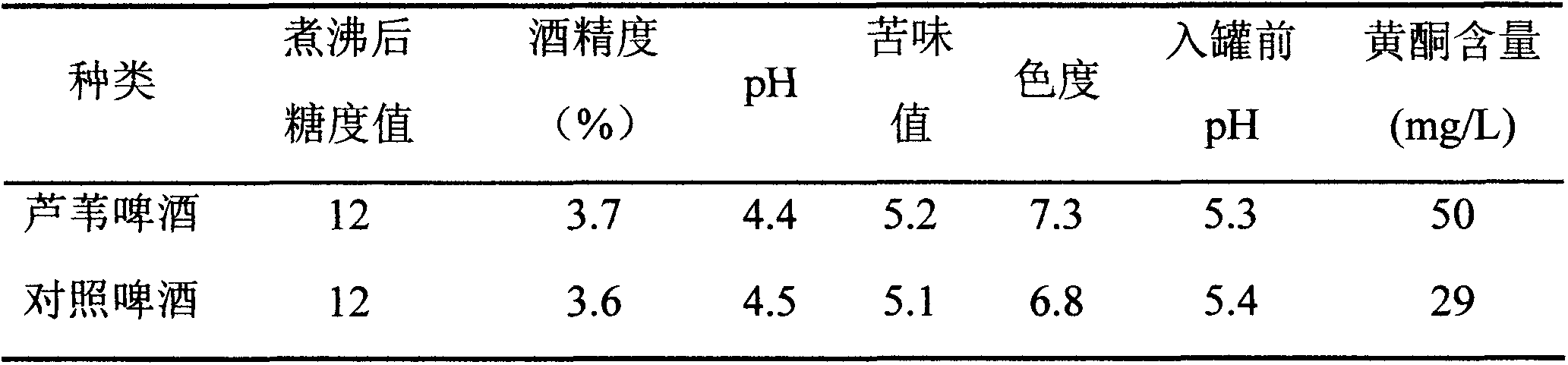

Examples

Embodiment 1

[0038] Produced by 100 liter micro-beer fermentation equipment

[0039] A reed health care beer is mainly prepared from the following raw materials in parts by weight:

[0040] 160 grams of reed leaf powder, 20 kilograms of barley malt, 1 kilogram of burnt barley, 100 grams of hops (including 80 grams of bitter hops and 20 grams of fragrant hops), and 100 grams of yeast.

[0041] A production process of the above-mentioned reed health-care beer, specifically comprising the following process steps:

[0042] (1) Reed pretreatment

[0043] After washing the collected fresh reed leaves, soak them in a 1-2% vitamin C aqueous solution by mass for 30 minutes, then soak them in boiling water for 5 minutes, put them in a dryer at 55°C for 12 hours, and dry them in the air When the water content is about 10%, pulverize with a pulverizer to a particle size of 50-100 mesh, divide it into small portions, that is, put every 10-20 grams of reed leaf powder into a pure cotton decoction bag,...

Embodiment 2

[0062] Fermentation with 30 liters of domestic fermentation equipment

[0063] A reed health care beer is mainly prepared from the following raw materials in parts by weight:

[0064] 40 grams of reed leaf powder, 5 kilograms of barley malt, 0.5 kilograms of burnt barley, 20 grams of hops (including 16 grams of bitter hops and 4 grams of fragrant hops), and 20 grams of dry yeast powder.

[0065] A production process of the above-mentioned reed health-care beer, specifically comprising the following process steps:

[0066] (1) Yeast activation

[0067] Weigh 20 grams of dry yeast powder such as Ayer Yeast, add to 500mL wort at 28°C to activate, shake in a shaker at low speed for 20 minutes;

[0068] (2) Reed pretreatment

[0069] Soak the collected fresh reed leaves in 500 ml of 1% vitamin C by mass fraction for 0.5 hours, wash the dust on the surface of the reed leaves with flowing pure water, soak them in boiling water for 5 minutes, take them out and put them in a dryer a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com