A method of treating dye wastewater by using modified straw

A technology for modifying straw and dye wastewater, which is applied in water/sewage treatment, chemical instruments and methods, textile industry wastewater treatment, etc. Strong ability, good cohesion effect, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Preparation of modified straw

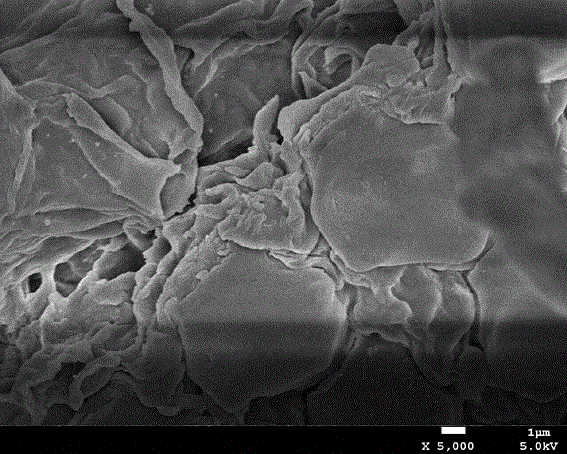

[0026] (1) Rice straw pretreatment

[0027] Weigh 10g of rice straw passed through a 20-mesh sieve and 20g of sodium hydroxide into a 1000ml beaker, add 200ml of distilled water and 100ml of 3% hydrogen peroxide at the same time, place the beaker on a magnetic stirrer, control the stirring rate to 300r / min, and the temperature at Stir at 5-10°C for 5-6h, then filter, rinse the product with distilled water until it is nearly neutral, and dry at 60°C to constant weight.

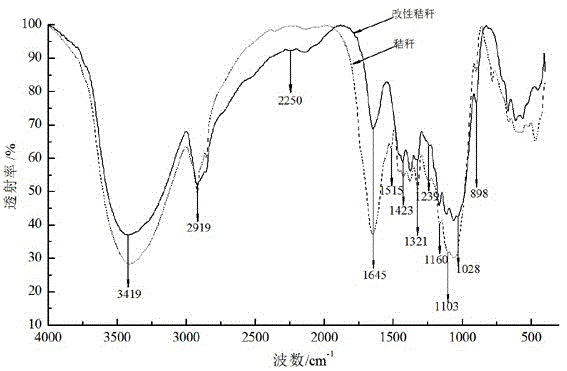

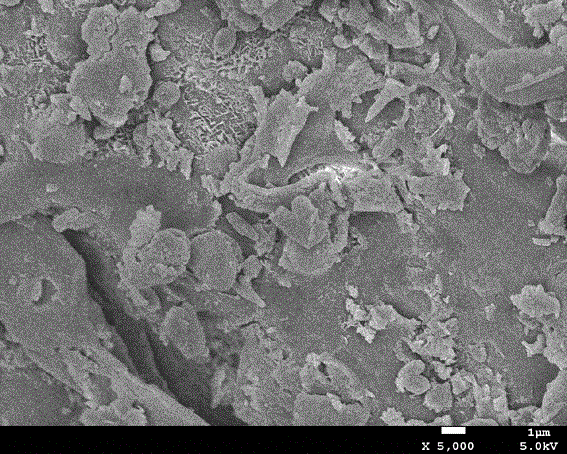

[0028] (2) Rice straw modification

[0029] ①Weigh 2g of the straw treated by (1), weigh 0.6g, 1g, 2g, 4g, and 6g of the modifier tetradecyltrimethylammonium chloride respectively and place them in a 1000ml beaker, add 200ml distilled water and 100ml concentration 3% hydrogen peroxide, put the beaker on a magnetic stirrer, filter at pH=7, temperature=60°C, stirring rate=500r / min, stirring time 4h, rinse the product with distilled water until neutral, Dry at 60°C to c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com