Grinding Fixtures for Support Plates

A support plate and grinding technology, which is applied in the direction of grinding the workpiece support, etc., can solve the problems of support plate clamping difficulty, cumbersome clamping operation, low work efficiency, etc., achieve simple operation, shorten the time required for clamping, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

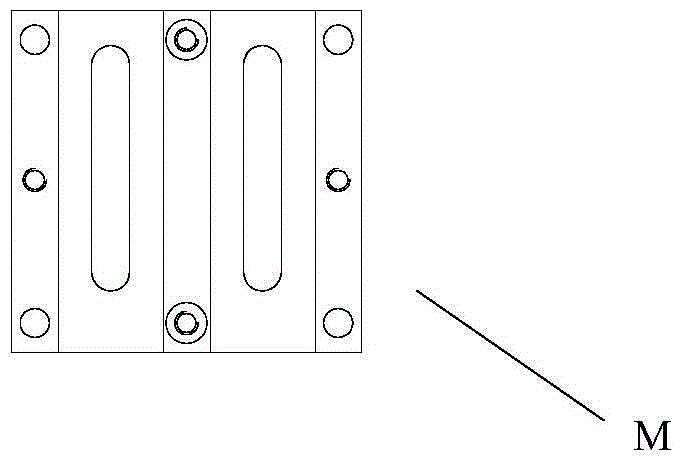

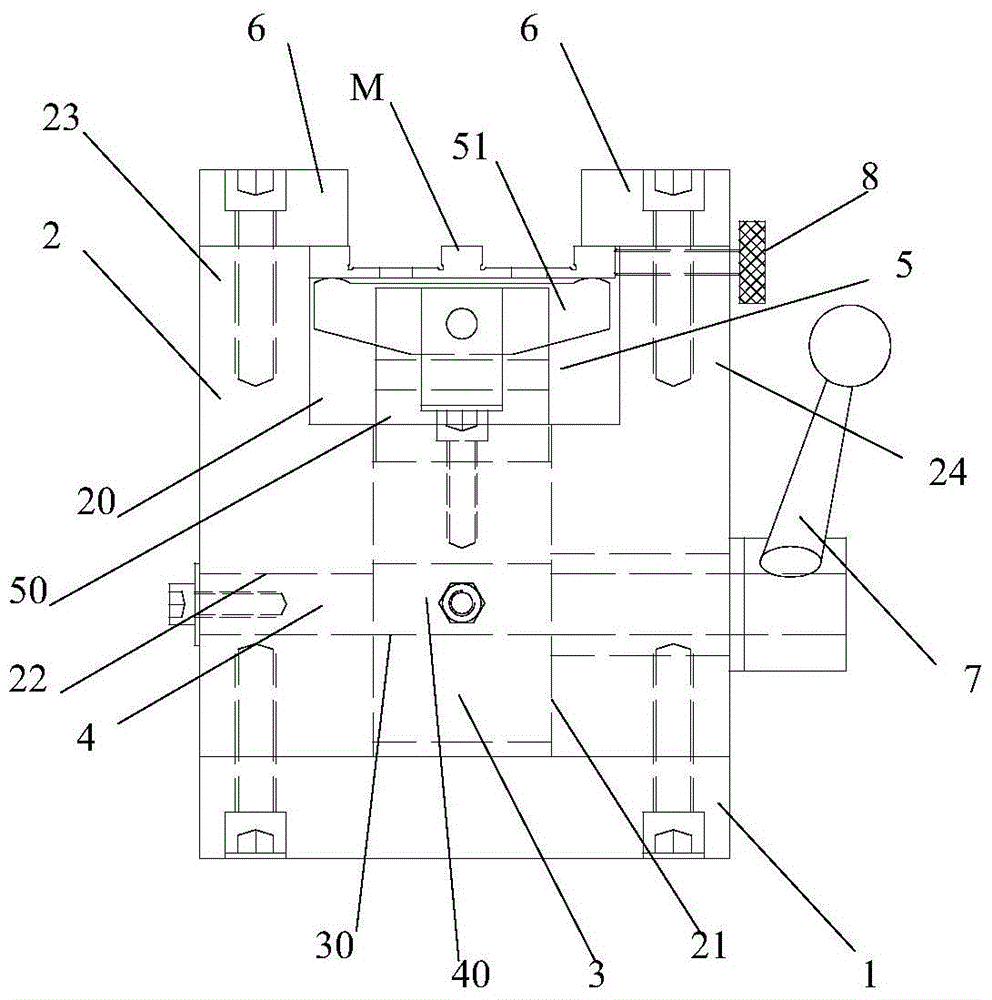

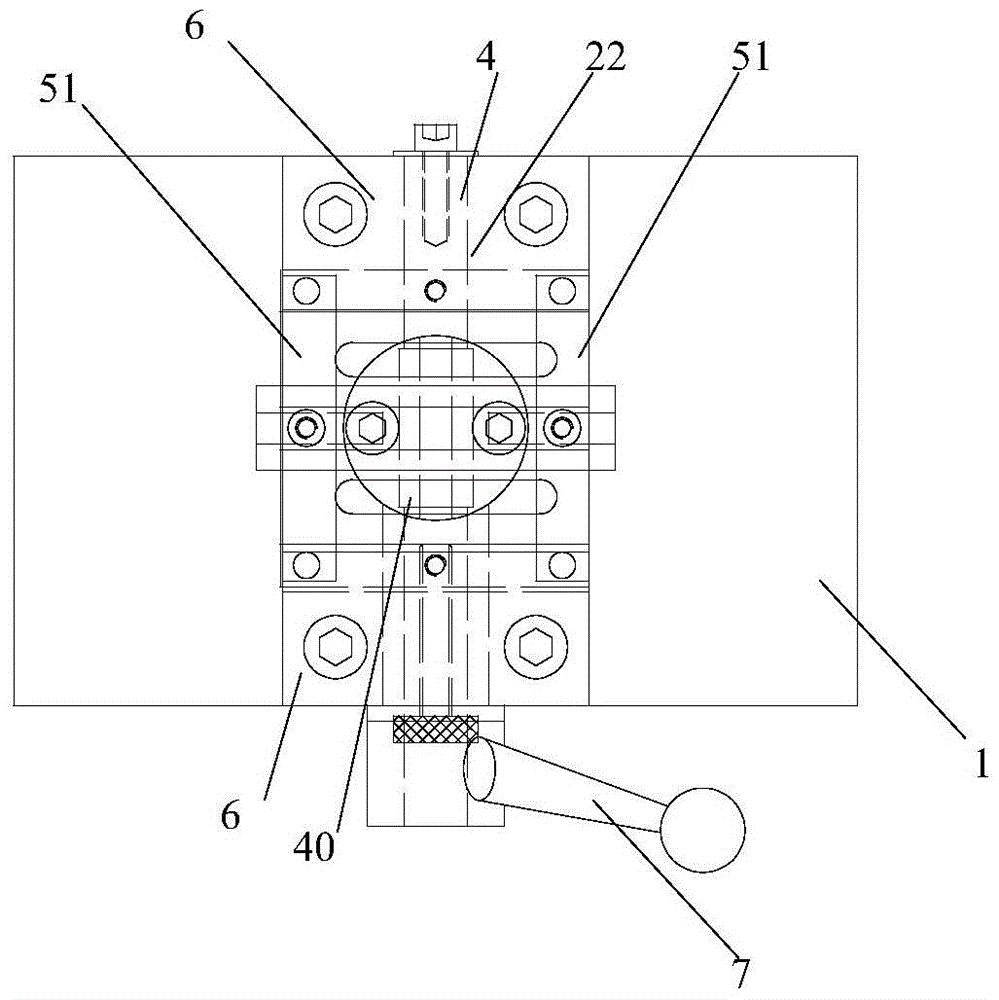

[0023] Next, a grinding jig for a support plate as an example of the present invention will be described based on the drawings.

[0024] figure 2 It is a schematic front view showing the grinding jig of the support plate of this invention. image 3 It is a plan view schematic diagram which shows the grinding jig of the support plate of this invention. Figure 4 It is a front schematic diagram which shows the slider of the grinding jig of the support plate of this invention. Figure 5 It is a side view schematic diagram which shows the slider of the grinding jig of the support plate of this invention. Image 6 It is a front schematic diagram which shows the bracket of the grinding jig of the support plate of this invention. Figure 7 It is a plan view schematic diagram which shows the bracket of the grinding jig of the support plate of this invention. Figure 8 It is a schematic front view showing the swing frame of the grinding jig of the support plate of this invention. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com