Clutch bearing groove rib manipulator

A manipulator and clutch technology, applied in the field of forging, to reduce the difficulty of debugging equipment and improve the efficiency of forging production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

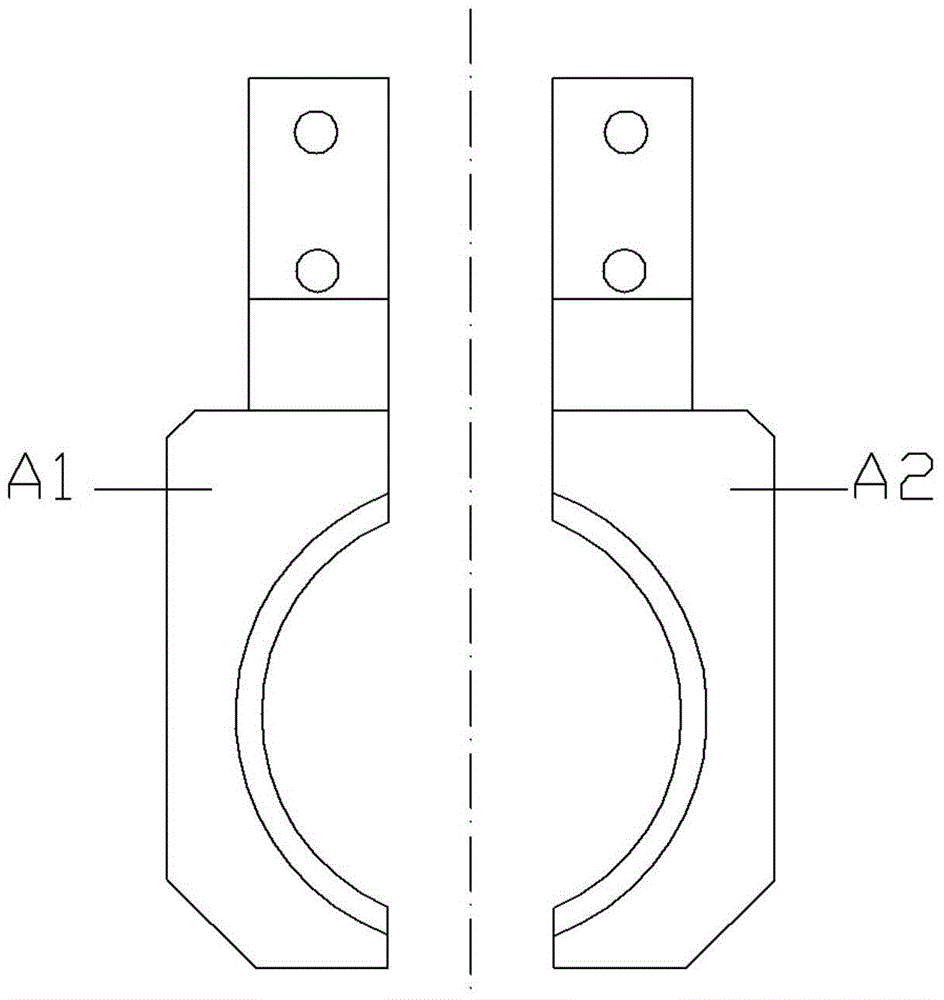

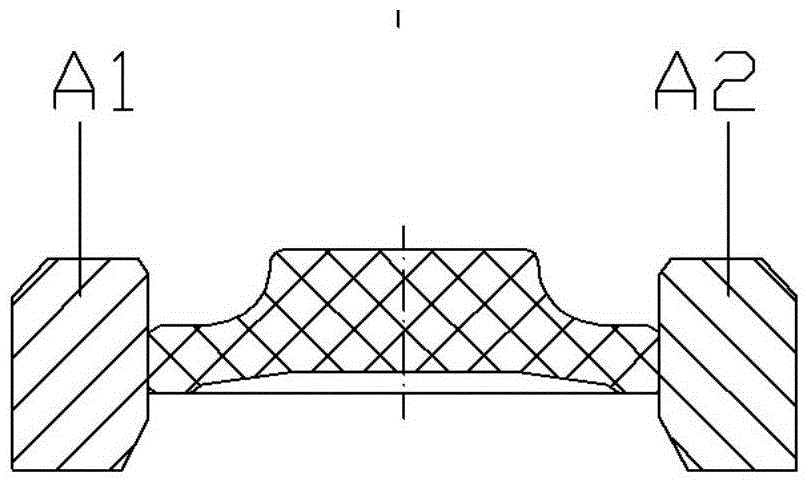

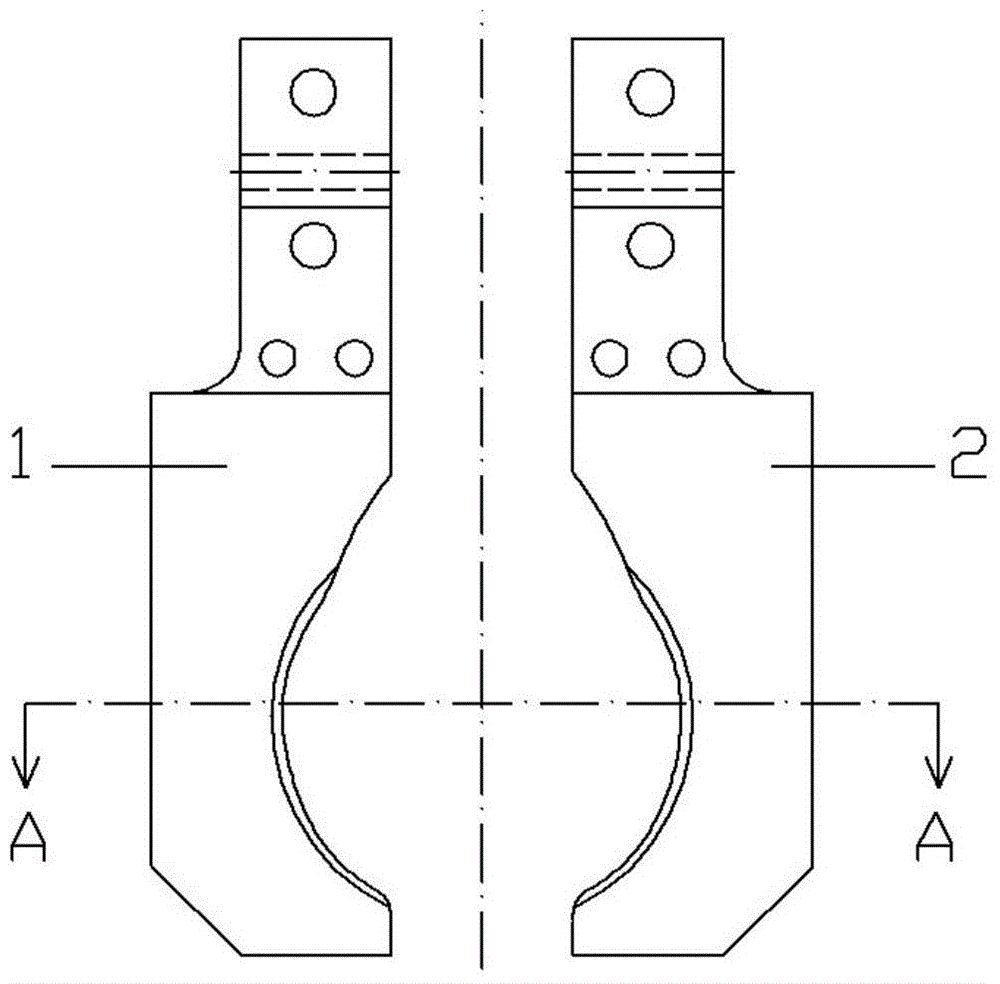

[0015] Example: see Figures 3 to 5 As shown, the clutch bearing groove rib manipulator includes the left clamp arm 1 and the right clamp arm 2 of the manipulator, the left clamp arm 1 and the right clamp arm 2 are symmetrical structures, and the clamping surface of the left clamp wall 1 is from top to The bottom is sequentially formed with a guiding slope 11, a homeopathic slope 12, a clamping straight surface 13 and a sidewall step surface 14, and the clamping surface of the right clamping wall 2 is sequentially formed with a right clamping arm guiding slope 21 and a right clamping surface from top to bottom. Arm along the inclined surface 22, the right clamping arm clamping straight surface 23 and the right clamping arm rib step surface 24, the guiding inclined surface 11 is inclined to the lower right, and the inclined surface 12 is inclined to the lower left.

[0016] The included angle a between the guide slope 11 and the vertical line L is 10 degrees.

[0017] Working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com