Lever-type loop

A lever-type, looper technology, used in bending workpieces, metal processing equipment, metal rolling, etc., can solve the problems of material leakage, insufficient lubrication of sleeve arms, and insufficient fixation of pressure rollers, and achieves simple overall structure design. The effect of reducing maintenance costs and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to deepen the understanding and recognition of the present invention, the present invention will be further described and introduced below in conjunction with the accompanying drawings.

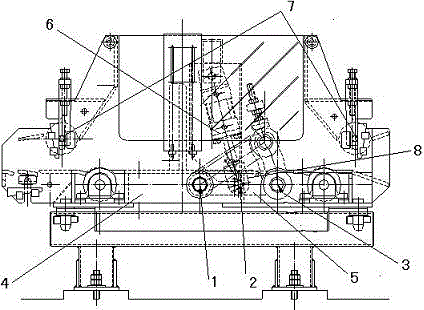

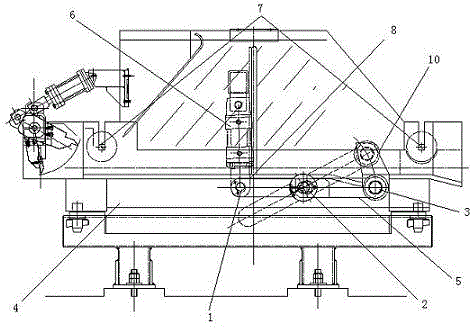

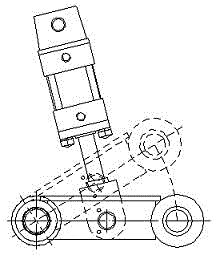

[0024] Such as figure 2 and 4 As shown, a kind of lever type looper comprises a looper frame 4, a sleeve arm 5, a sleeve cylinder 6, a pressure roller device 7, and a sleeve roller 10, and the looper frame 4 is fixedly connected with the work surface, The sleeve arm 5 is movably connected to the looper frame 4 using the first movable hinge 1 and the third movable hinge 3, and the hinge point of the sleeve cylinder 6 is installed at the rear end of the fixed hinge 2 to form a Balanced leverage effect, the jacketing cylinder 6 is fixed and hinged on the jacketing arm 5 through the cylinder ear plate 8, the jacketing shaft of the jacketing roller 10 is provided with an oil filling hole 9, and the oil and gas pipe is connected to the jacketing arm 5. The shaft of the set roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com