Chip-scale gas-liquid separator and control system thereof

A liquid separator and control system technology, which is applied in laboratory utensils, material excitation analysis, chemical instruments and methods, etc., can solve the problems of difficult gas-liquid manipulation, unstable flow rate of compressible gas, etc. Easy to upgrade and the effect of shortening the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

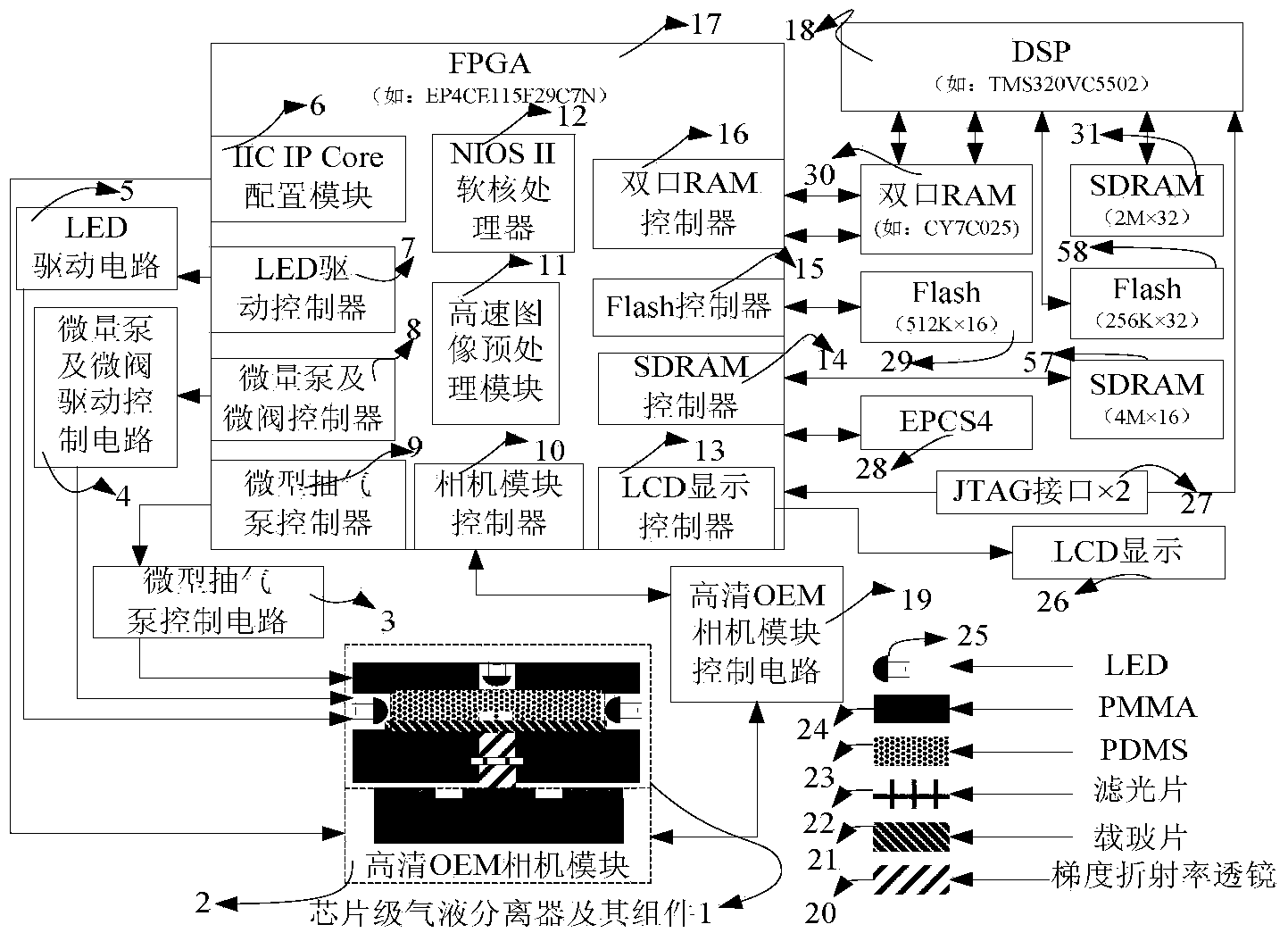

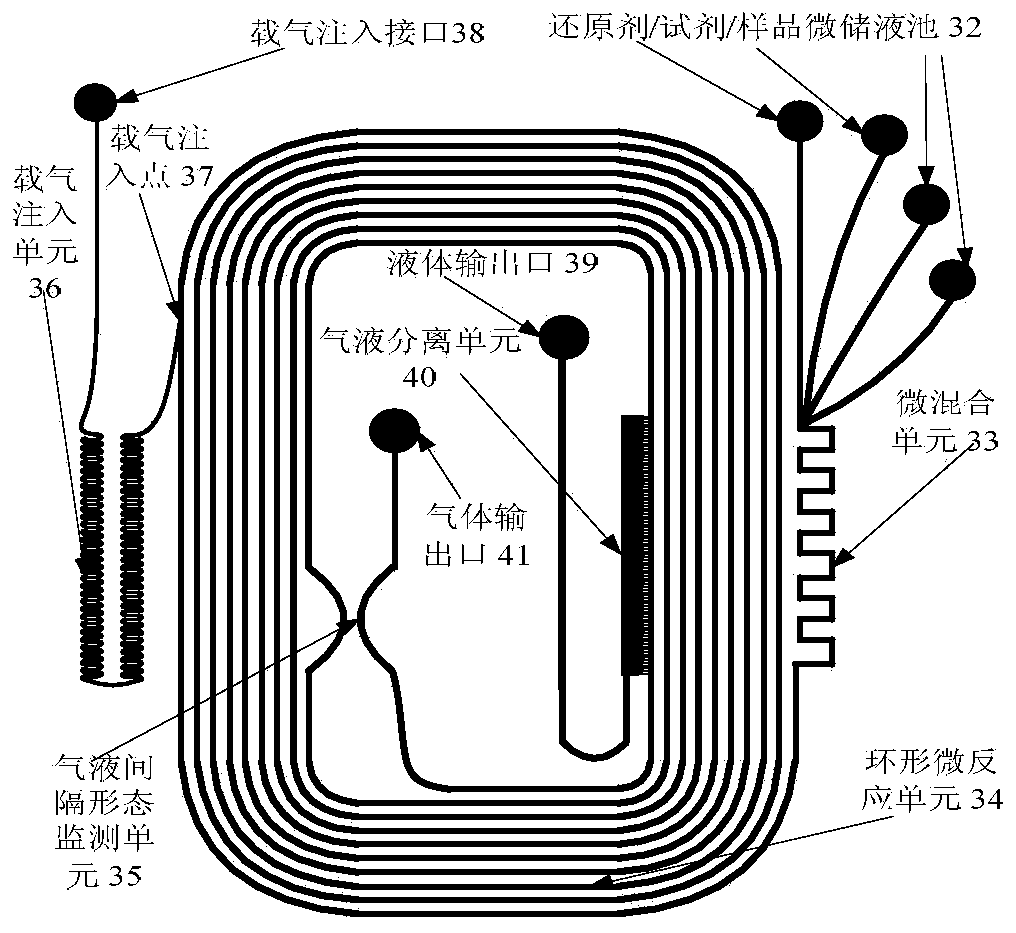

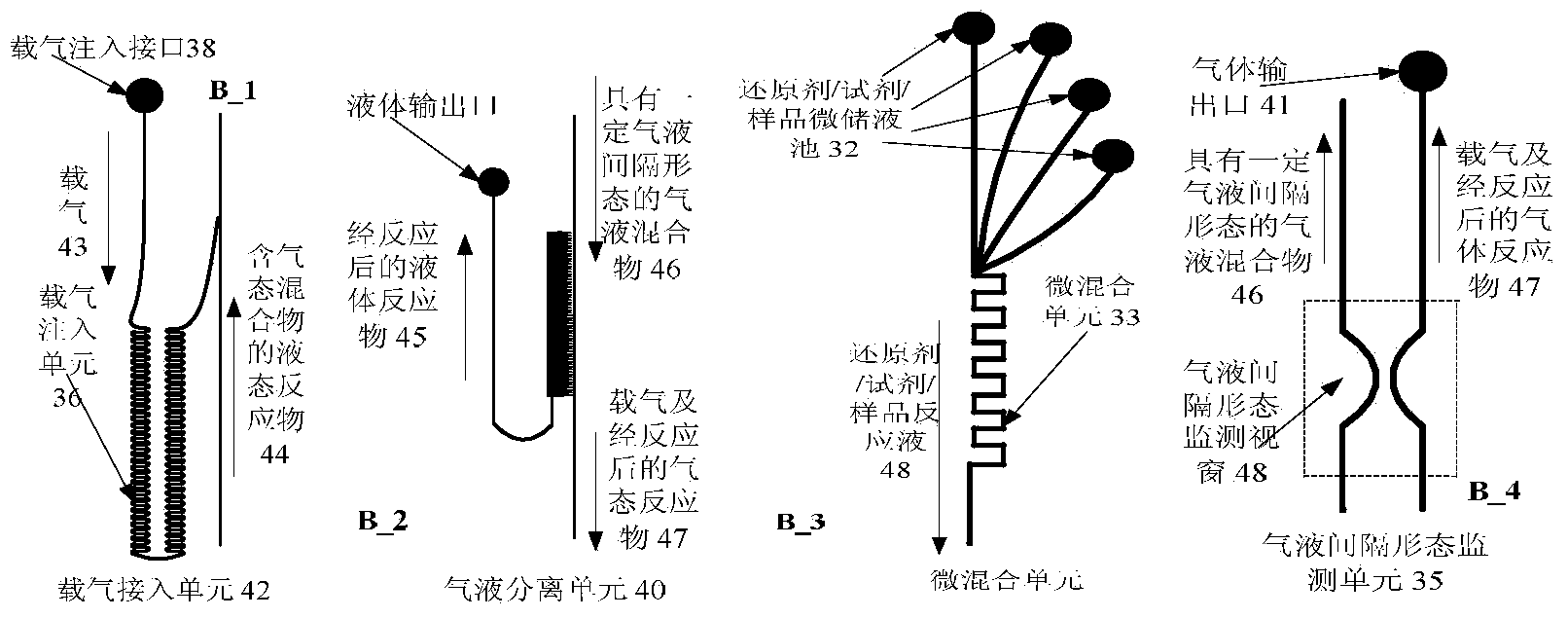

[0066] figure 1 It is a schematic diagram of the control system based on the chip-level gas-liquid separator, figure 2 , image 3 , Figure 4 A schematic diagram of the structure of the chip-level gas-liquid separator and its components is shown. figure 2 It can be seen that the chip-level gas-liquid separator is made of PDMS 24 and transparent glass slide 22 using MEMS technology, and the upper and lower sides of the chip and gas-liquid separator are fixed with PMMA 24. 3 LEDs 25 are placed on the right for illumination when the CMOS / CCD image sensor 49 monitors the gas-liquid interval shape, and 2 gradient refractive index lenses 20 and filter are placed directly below the gas-liquid interval shape monitoring unit 35 of the chip-level gas-liquid separator. The light sheet 23 enables the CMOS / CCD image sensor 49 to clearly collect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com