Large-power microwave vertical type reactor

A reactor and high-power technology, applied in chemical instruments and methods, chemical/physical/physicochemical processes of energy application, chemical/physical/physicochemical processes, etc., can solve the problem of low efficiency of extremely high-power microwave reactors The unreasonable installation position of the magnetron and other problems can achieve the effects of increasing productivity, reducing energy consumption, and reducing the yield of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

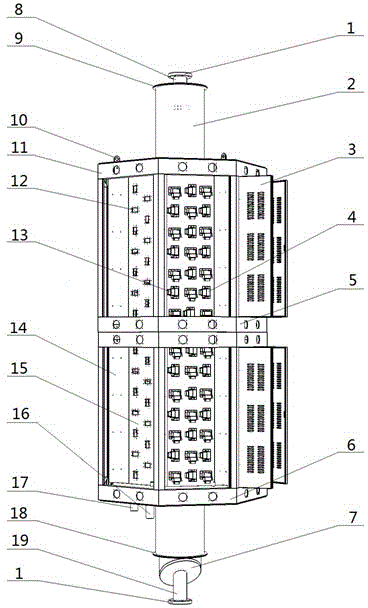

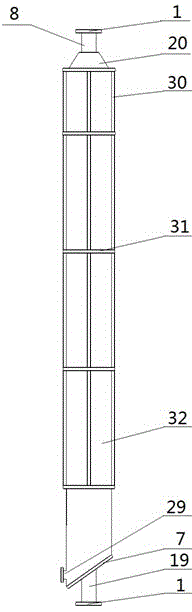

[0040] like Figures 1 to 11 As shown, the high-power microwave vertical reactor includes an external microwave cavity and a reaction inner tube built in the external microwave cavity;

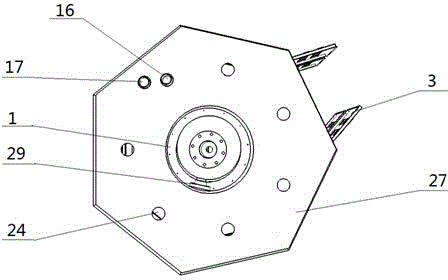

[0041]The reaction inner tube built in the external microwave cavity includes an inner tube narrow tube flange 1, an inner tube upper end thin tube 8, a container boss 20, a container main body 32, an inner tube lower end slope 7, The thin tube 19 at the lower end of the inner tube and the thin tube flange 1 of the inner tube, the container rib plate is provided outside the container main body 32, and the residual liquid discharge port 29 is provided on the side of the slope 7 at the lower end of the inner tube;

[0042] The external microwave cavity is composed of seven cavity plates in a regular heptagonal shape, and the external microwave cavity is divided into a microwave cavity cover and a cavity connected to the microwave cavity cover on both sides through cavity plate ribs 14 from the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com