Process for manufacturing decavitamin nanoemulsion for livestock and poultry

A multivitamin and manufacturing process technology, applied in the field of feed additive product processing, can solve the problems of limited digestion and absorption efficiency of livestock and poultry, bacterial infection of preservatives, residual risks, etc., to shorten the breeding cycle, reduce breeding costs, and facilitate digestion and absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

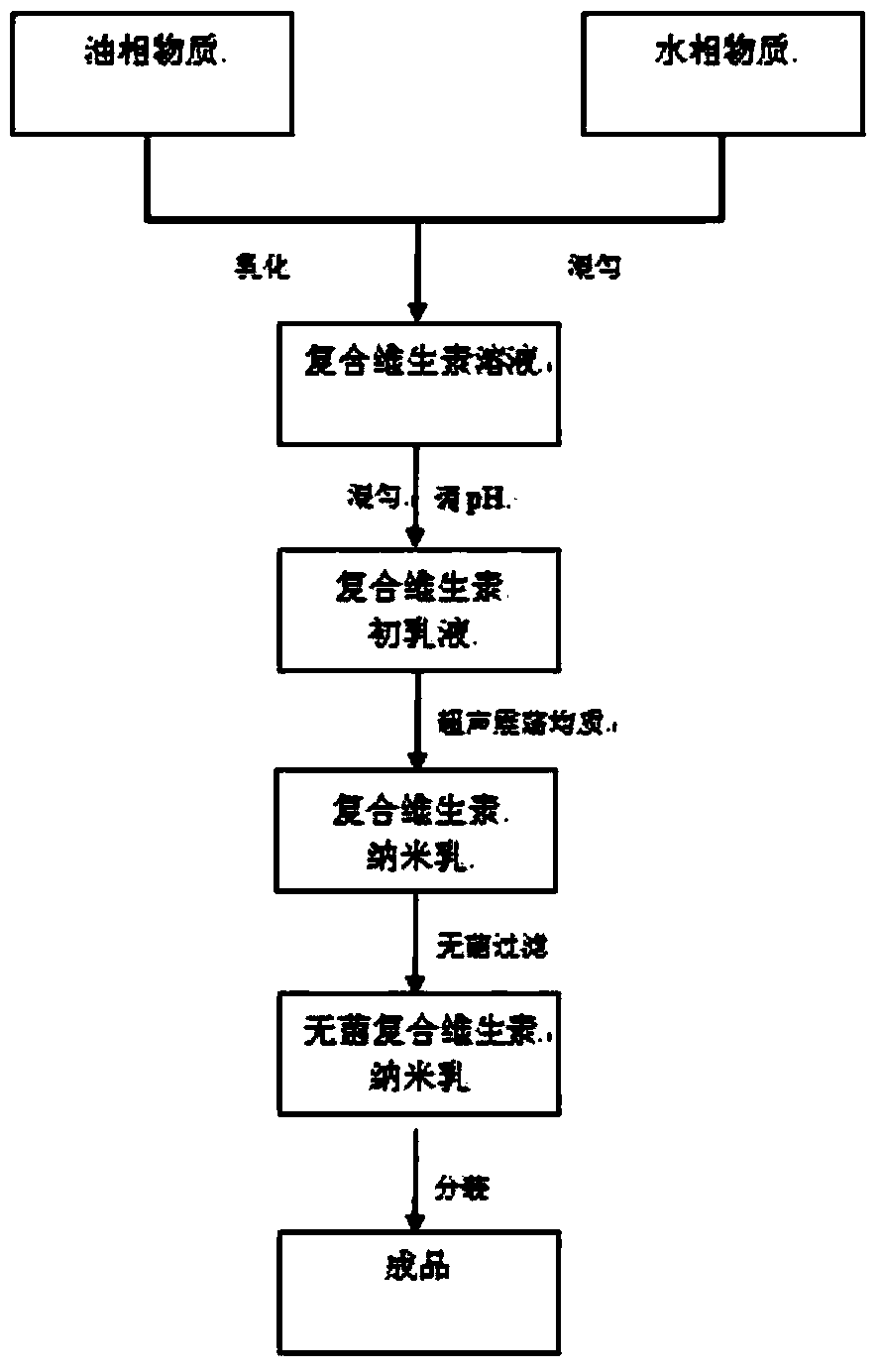

Method used

Image

Examples

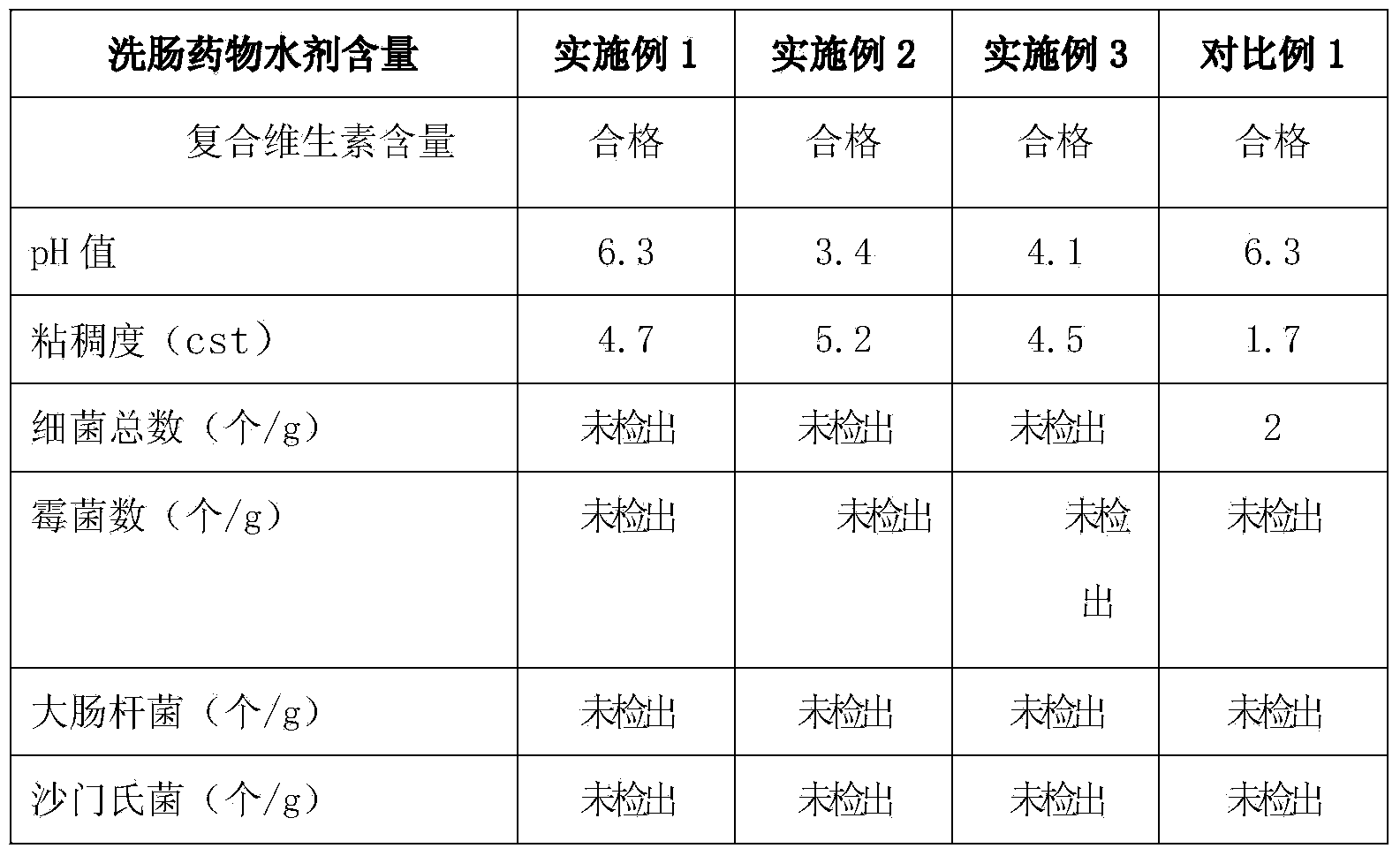

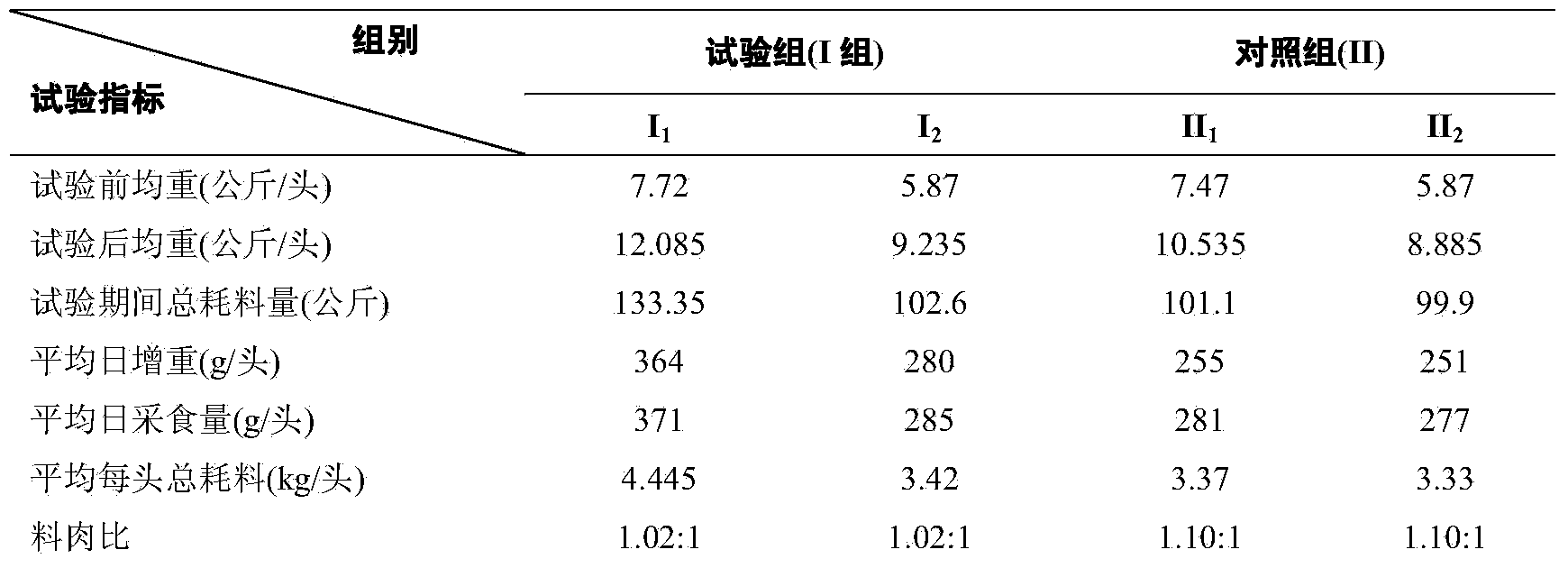

Embodiment 1

[0046] The oil phase substance and the water phase substance are prepared for use according to the mass ratio of 2:5; the oil phase substance vitamin A 1 : Vitamin D 2 : Vitamin D 3 : Vitamin E: BTH: Tween-80: Glycerin: Refined lard: Potassium hydroxide according to the formula mass ratio 0.02:0.001:0.001:0.08:0.006:0.60:0.10:0.03:0.01; Electric heating and temperature-controlled thickening tank, heating and stirring to melt and mix the refined lard, and then drop the prepared potassium hydroxide aqueous solution with a concentration of 50% into the refined lard at a speed of 18d / min. After the aqueous solution is added dropwise, under the condition of temperature of 60°C, with a stirring speed of 60rpm, heat preservation and stirring for 30min, then add the rest of the oil phase substances in the formula into the emulsion containing refined lard and potassium hydroxide. Under the condition of 60°C, keep warm and stir for 80 minutes to fully mix the oil phase substance with ...

Embodiment 2

[0052] The oil phase substance and the water phase substance are prepared for use according to the mass ratio of 5:2, and the oil phase substance vitamin A 1 : Vitamin D 2 : Vitamin D 3 : Vitamin E: BTH: Tween-80: Glycerin: Refined lard: Potassium hydroxide according to the formula mass ratio 0.04:0.003:0.003:0.13:0.010:0.75:0.20:0.06:0.03; Electric heating and temperature-controlled thickening tank, heating and stirring to melt and mix the refined lard, and then drop the prepared potassium hydroxide aqueous solution with a concentration of 50% into the refined lard at a speed of 28d / min. After the dropwise addition of the aqueous solution is completed, under the condition of 35° C., with a stirring speed of 80 rpm, keep stirring for 40 minutes, and then add the rest of the oil phase substances in the formula into the emulsion containing refined lard and potassium hydroxide. Under the condition of 60°C, keep warm and stir for 80 minutes to fully mix the oil phase substance w...

Embodiment 3

[0057] The oil phase substance and the water phase substance are prepared for use according to the mass ratio of 1:1, and the oil phase substance vitamin A 1 : Vitamin D 2 : Vitamin D 3 : Vitamin E: BTH: Tween-80: Glycerin: Refined lard: Potassium hydroxide according to the formula mass ratio 0.02:0.003:0.001:0.13:0.010:0.75:0.20:0.03:0.01; Electric heating and temperature-controlled thickening tank, heating and stirring to melt and mix the refined lard, and then drop the prepared potassium hydroxide aqueous solution with a concentration of 50% into the refined lard at a speed of 19d / min, when potassium hydroxide After the dropwise addition of the aqueous solution is completed, at a temperature of 38° C., with a stirring speed of 63 rpm, keep stirring for 31 minutes, and then add the rest of the oil phase substances in the formula to the emulsion containing refined lard and potassium hydroxide. Under the condition of 61 ℃, heat preservation and stirring for 67 minutes, so th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com