Initial marine processing method for ship-fished squid and special equipment thereof

A processing equipment and squid fishing technology, which is applied in the processing and application of processed fish and cephalopods, can solve the problems of reduced squid quality, reduced operation efficiency, high labor intensity, etc. The effect of transportation cost and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

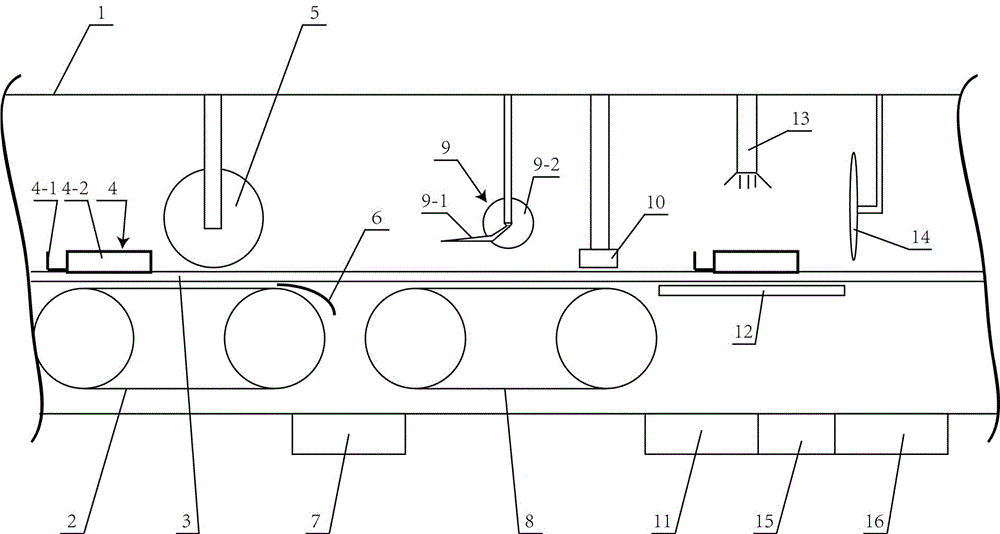

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0019] The technological process of the method of the invention is as follows: squid fishing, seawater cooling storage, grading, head removal, viscera, fins, traying, quick freezing, packaging and storage.

[0020] Method embodiment of the present invention:

[0021] 1. Both hand-caught and machine-caught squid are sent to the seawater cooling cabinet in the ship's warehouse by conveyor belt. The temperature of the seawater in the cooling cabinet is below 10°C. At this temperature, microorganisms reproduce slowly, preventing the squid from deteriorating and ensuring its freshness. In addition, the squid cooled by seawater is cleaned once to remove surface pollution.

[0022] 2. Grading, the squid in the seawater cooling cabinet is graded according to the size, which is convenient for the mechanical division of the subsequent process.

[0023]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com