Inoculation, nursing and primordium inducing factory system of Pleurotus eryngii

A technology for industrialization and king oyster mushrooms, which is applied in mushroom cultivation, cultivation, plant cultivation and other directions, can solve the problems of inability to carry out continuous production, long sterilization and disinfection time, and frequent entry and exit of personnel, so as to shorten production time and disinfection time. The effect of short, reduced investment and maintenance operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

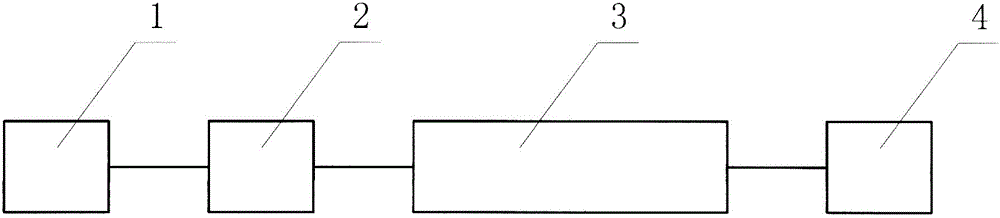

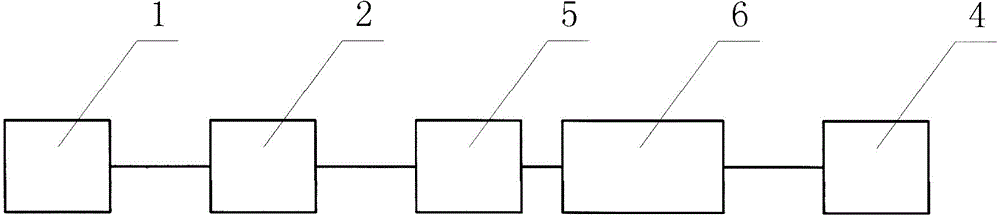

[0013] figure 2 It is a schematic flow chart of the industrialized system cultivation technology of Pleurotus eryngii inoculation, cultivation and cultivation Cui Lei of the present invention, batching and bagging are carried out in the batching workshop (1), and sterilization and cooling are carried out in the sterilization workshop (2), which is different from the prior art The difference is that the stage of mycelium cultivation is divided into two stages: the first-stage mycelial cultivation and the second-stage mycelial cultivation. 5) The construction area is 1 / 6 of the conventional mycelium cultivation workshop (3). The first-phase mycelium cultivation time is 5 days, the air relative humidity is 60%, and the temperature is 24°C; after 5 days of inoculation, it is moved to the second-phase cultivation workshop ( 6), the second-stage mycelial culture and primordium (cui lei) are carried out in the second-stage culture workshop (6), the second-stage mycelium culture is 2...

Embodiment 2

[0015] According to the Pleurotus eryngii inoculation culture Cui Lei factory system described in Example 1, the second phase of the cultivation workshop is 40 independent rooms, and there is one room every day where the intermediate products of the primordia are moved to the fruiting workshop (4) Mushroom cultivation is carried out, and the empty rooms in circulation are disinfected, realizing the uninterrupted continuous industrial production in the whole process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com