Substrate with transparent electrode, manufacturing method thereof, and touch panel

A technology of transparent electrodes and transparent electrode layers, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve problems such as no research, and achieve the effect of improving identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

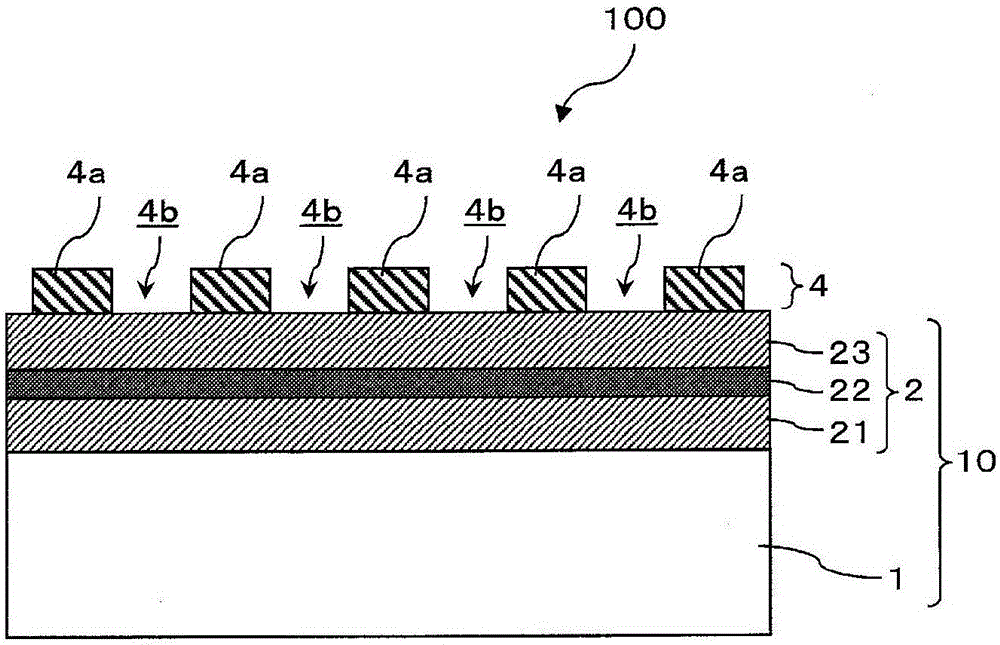

[0111] On one side of a biaxially stretched PET film with a thickness of 188 μm and a hard coat layer (refractive index 1.53) made of polyurethane resin formed on both sides, silicon Oxide (SiO x Layer) composed of medium refractive index transparent dielectric layer (first dielectric layer), high refractive index transparent dielectric layer (second dielectric layer) composed of niobium oxide, and silicon oxide (SiO 2 ) composed of a low refractive index dielectric layer (third dielectric layer).

[0112] First, using B-Si as the target material, while introducing oxygen / argon (20sccm / 400sccm) mixed gas into the device, the pressure in the device is 0.2Pa, the substrate temperature is -20°C, and the power density is 1.4W / cm 2 sputtering under conditions. Obtained SiO y The film thickness of the layer was 5 nm, and the refractive index was 1.65.

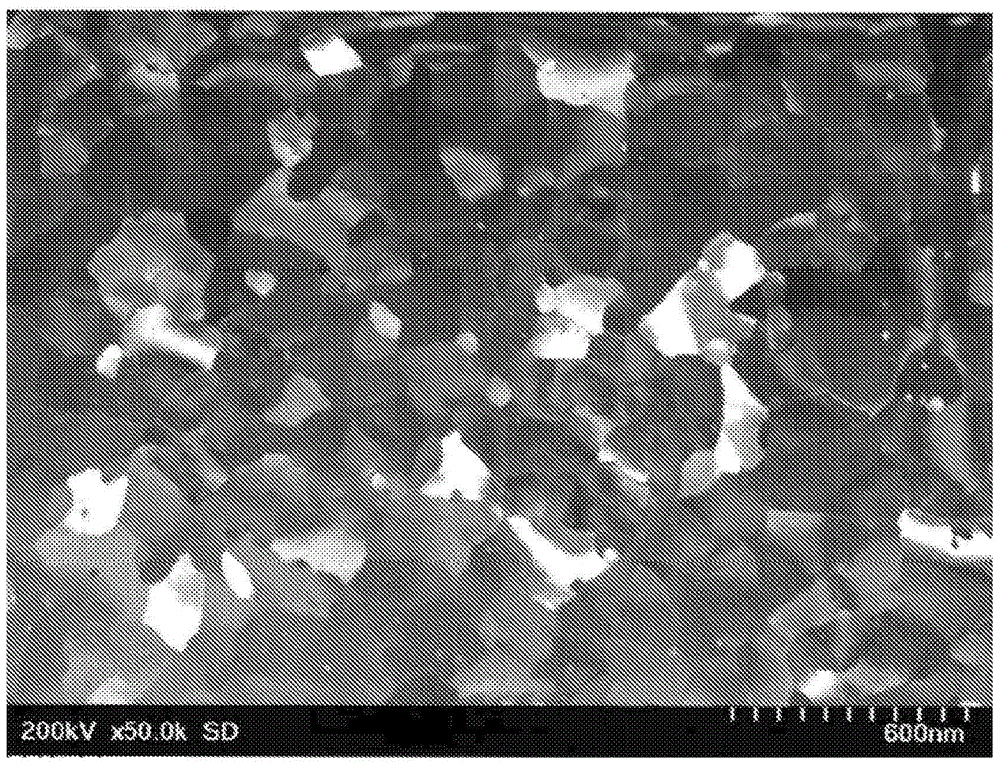

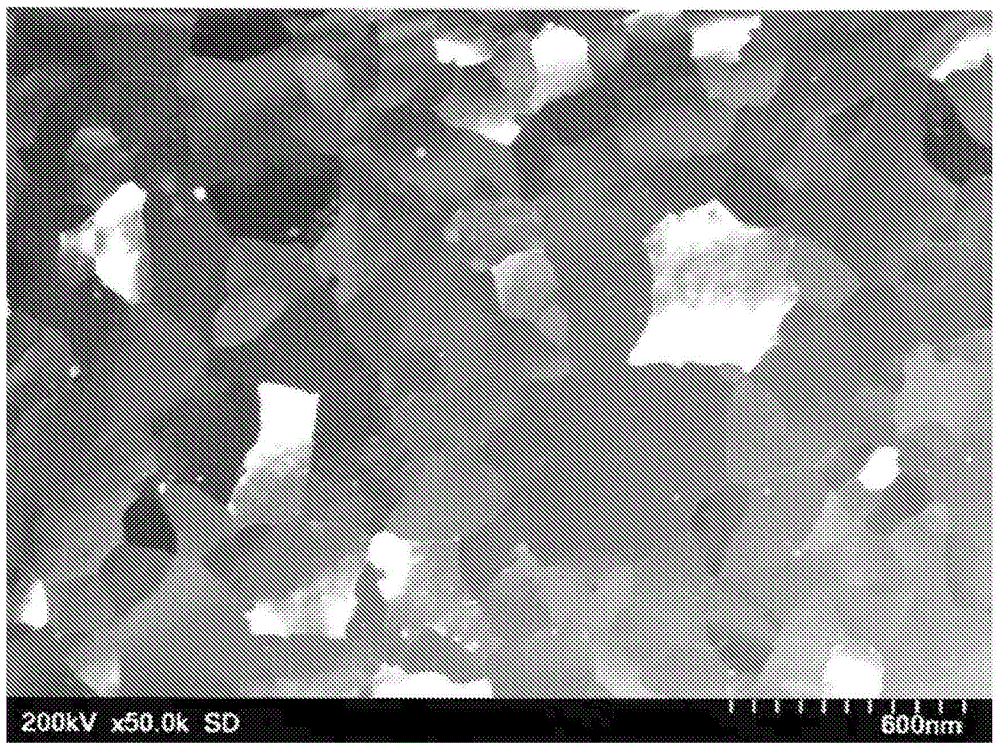

[0113] In the SiO x A high refractive index transparent dielectric layer is formed on the layer. Using niobium (Nb) as the ta...

Embodiment 2~9 and comparative example 1~3

[0119] Film thickness d of the second dielectric layer 2, The film thickness d of the third dielectric layer 3 And the film thickness of the transparent electrode layer was changed as shown in Table 1. Other than that, in the same manner as in Example 1, after forming the first dielectric layer, the second dielectric layer, the third dielectric layer, and the transparent electrode layer sequentially, patterning and heat treatment of the transparent electrode layer were performed.

Embodiment 10

[0122] The magnetic flux density at the time of forming the transparent electrode layer can be adjusted to 16 mT by changing the permanent magnet attached to the sputtering apparatus. The voltage of the MF power supply during sputtering film formation was 511V. Except for this, patterning and heat treatment of the transparent electrode layer were performed after sequentially forming the first dielectric layer, the second dielectric layer, the third dielectric layer, and the transparent electrode layer in the same manner as in Example 1 above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com