Wheel balance weight

A counterweight and wheel technology, which is applied in the direction of balancing rotating bodies, springs/shock absorbers, and vibration suppression adjustments, can solve problems such as difficult to visually identify the position of the center of gravity, difficult to visually identify the position of the center of gravity, and enlarge the axial direction. To achieve the effect of improving assembly workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention has been generally described above, and the present invention can be further understood by referring to specific preferred embodiments, which are provided in this application for illustration only, and are not intended to limit the scope of the appended claims.

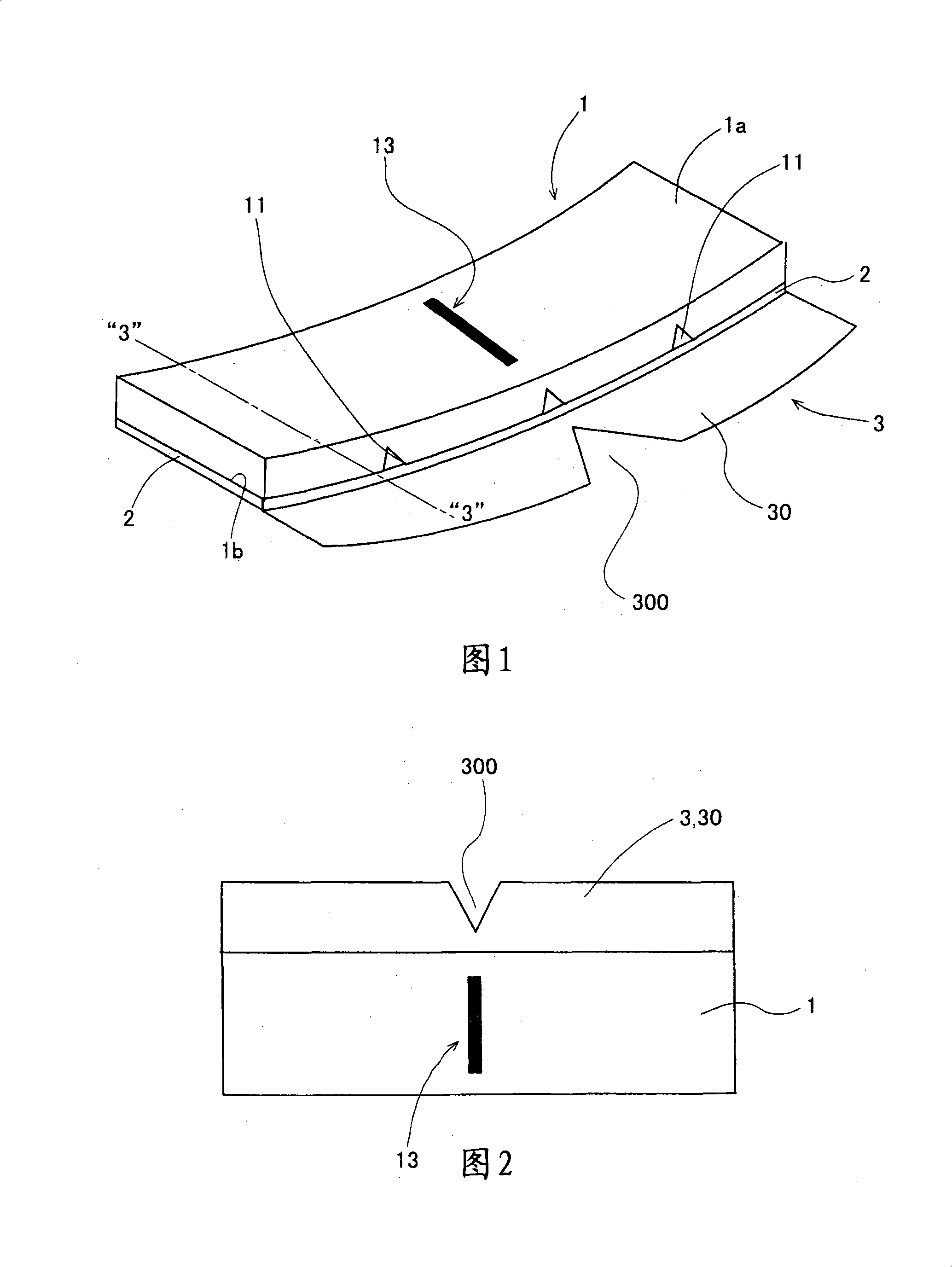

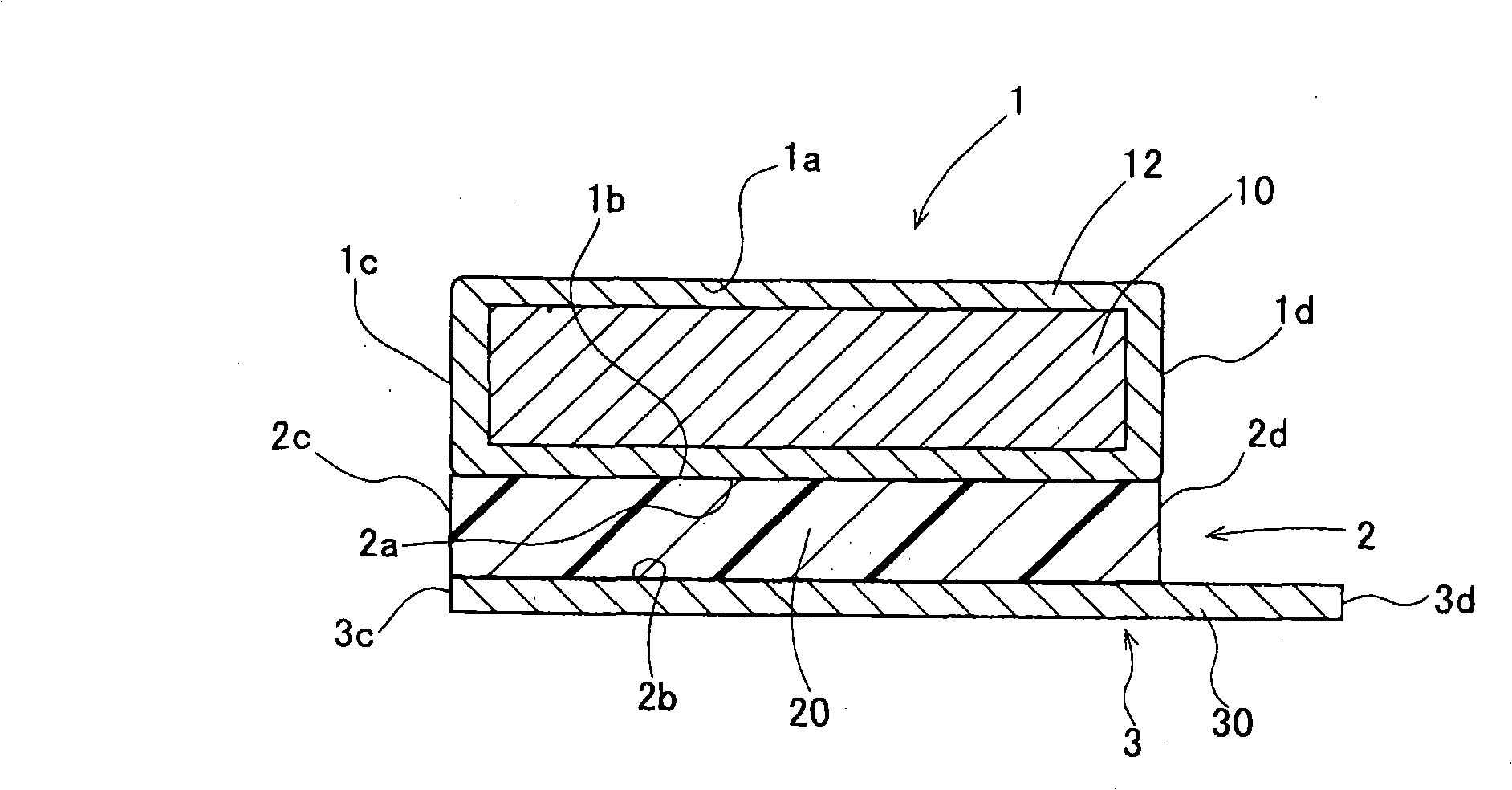

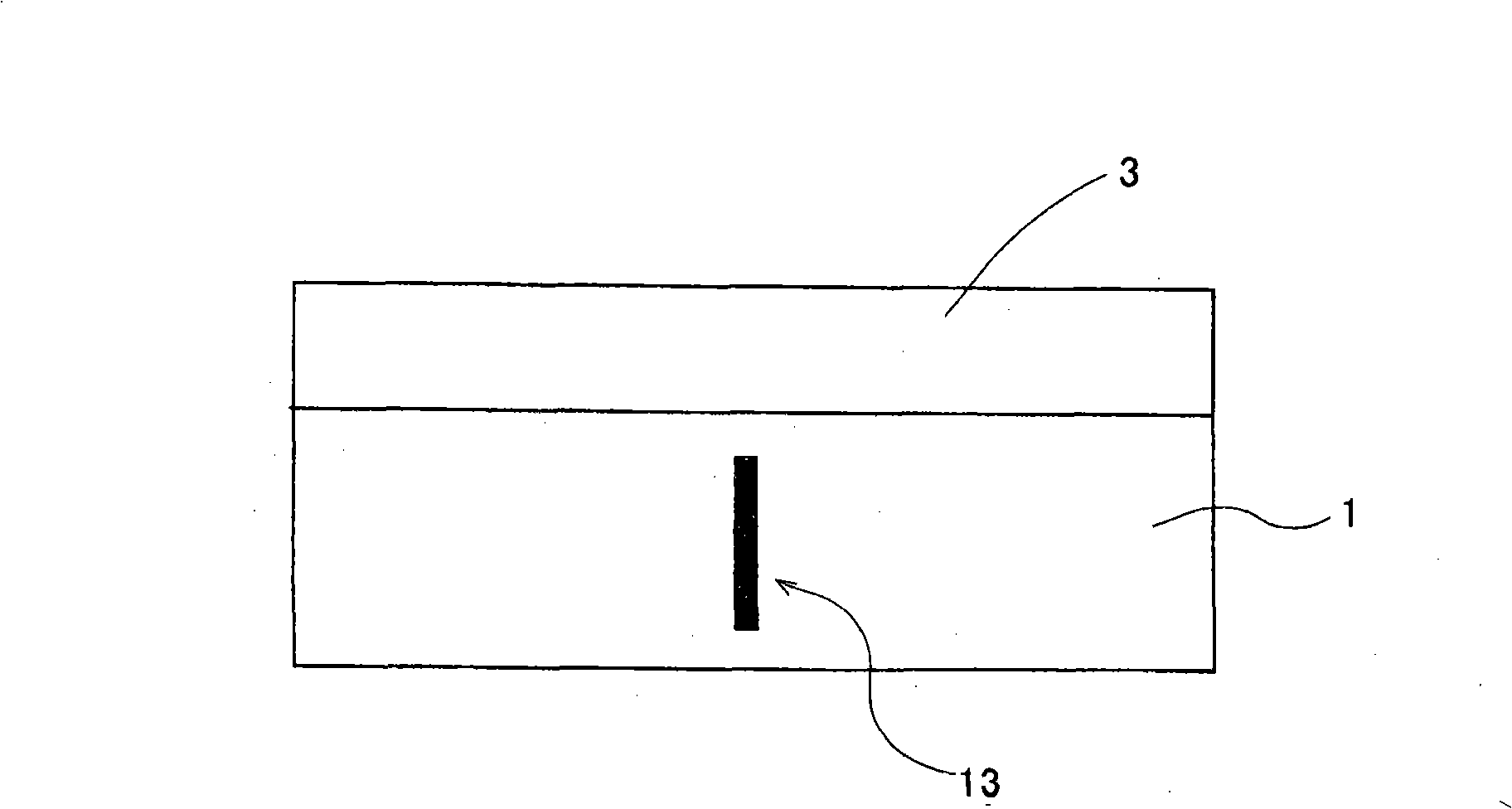

[0030] A wheel balance weight according to the present invention includes a weight body, an adhesive seal, a release coated paper; and a protrusion.

[0031] The weight body is a component part, which is formed into a substantially strip shape, and is made of metal. The weights have opposite front and rear surfaces, which are arranged back-to-back. When the wheel balance weight of the present invention is assembled with a wheel, the weight can counteract unbalanced conditions on the wheel. Since the weight body is made substantially in the shape of a strip, the weight body can be easily adjusted to be arc-shaped in the longitudinal direction by applying a load thereto in the thickness dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com