Motor stator

A motor stator and frame technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of inability to accurately control the exact position, low utilization rate of frame winding, contact between enameled wire and iron core, etc., to reduce enameled wire damage, The effect of saving installation process and increasing the amount of winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

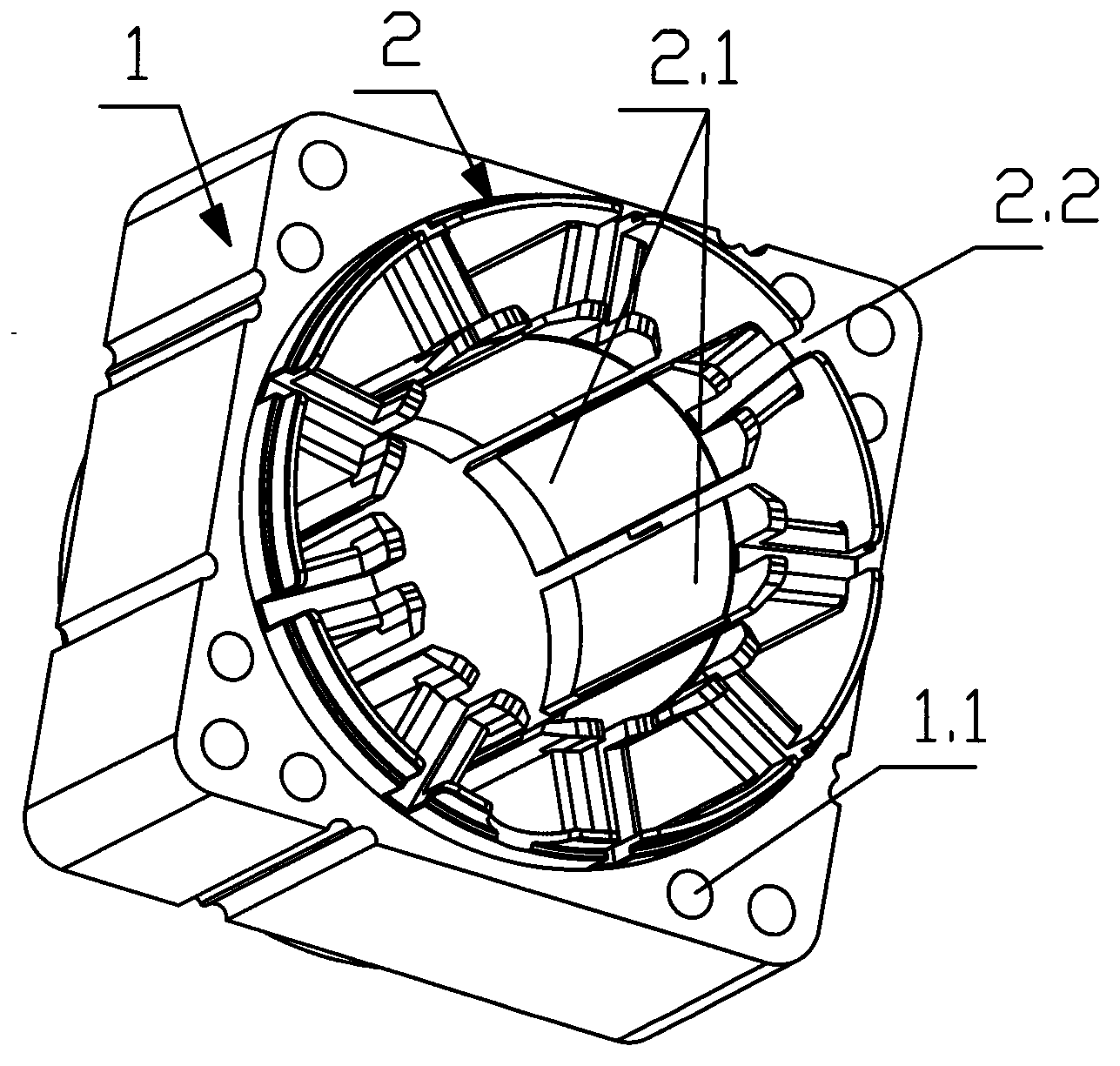

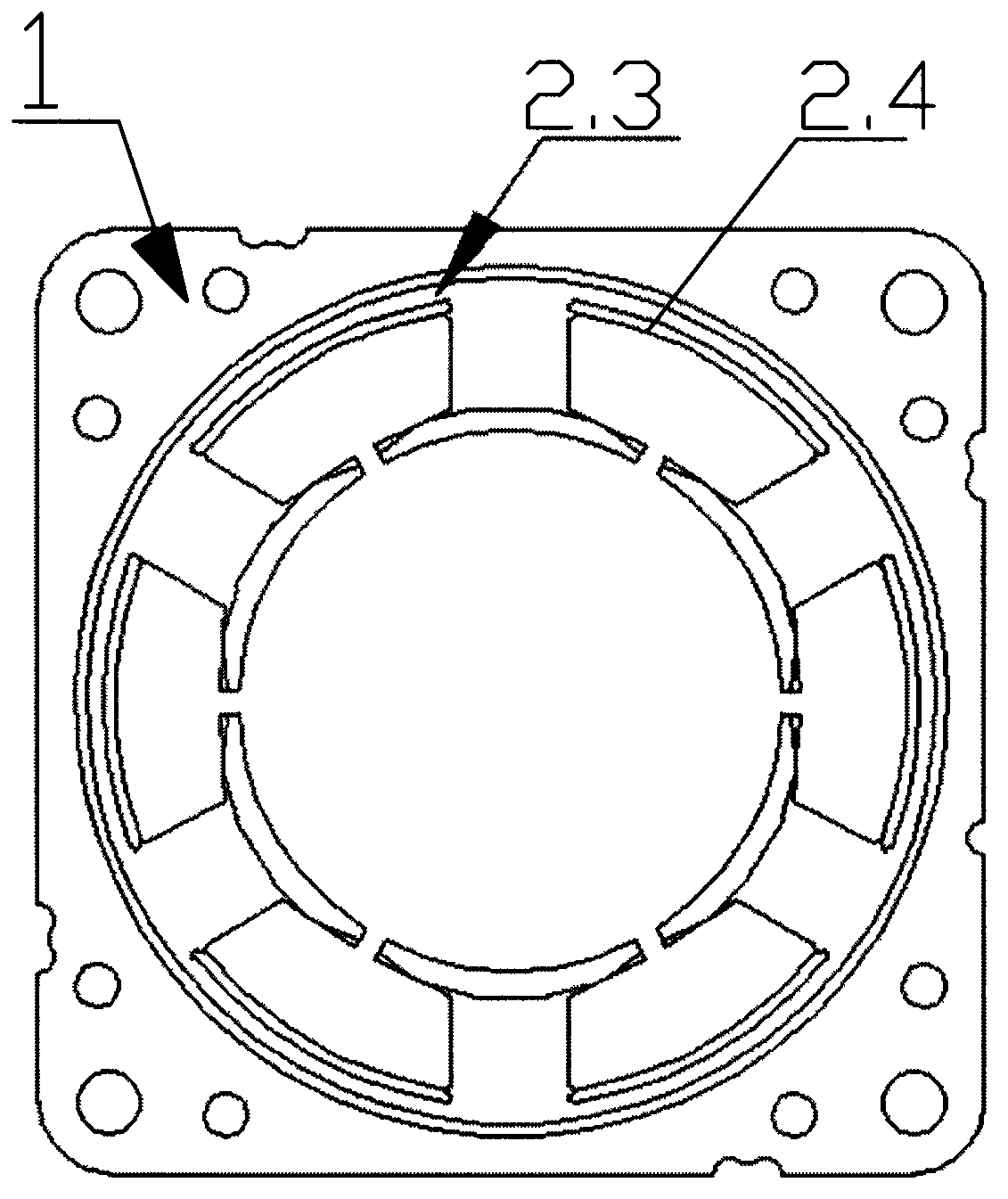

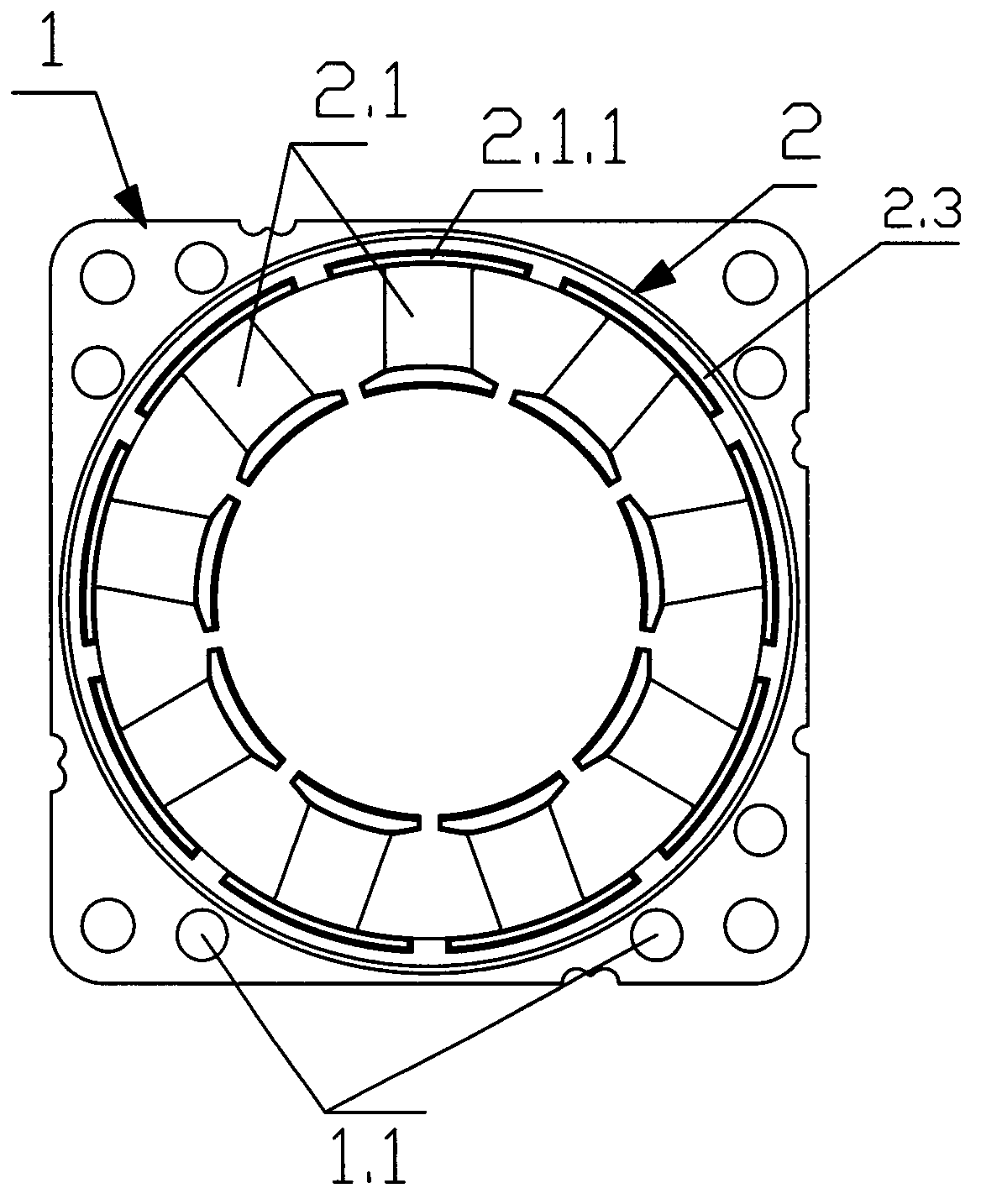

[0022] figure 1 It is a three-dimensional schematic view seen from the front side of the skeleton of the present invention, figure 1 The coil is not shown in. in figure 1 , The connecting lines between different components indicate that they have a connection relationship or a corresponding relationship between mounting holes.

[0023] Such as figure 1 As shown, a motor stator of the present invention includes an iron core 1, a coil, and a skeleton 2. The iron core 1 has a perforation in the center. The iron core 1 has a variety of molding methods. This embodiment uses the most common method at present, namely The iron core 1 is formed by successively stacking and pressing a plurality of silicon steel sheets, each silicon steel sheet is provided with a through hole in the center, and the multiple silicon steel sheets are superimposed to form a perforation of the iron core 1. The above structure is the same as most stator structures in the prior art, which can be clearly understoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com