Projection curtain with high luminance gains and wide view angles

A technology of projection screen and wide viewing angle, applied in the field of projection screen, can solve the problem that the projection screen cannot achieve high brightness gain and wide viewing angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

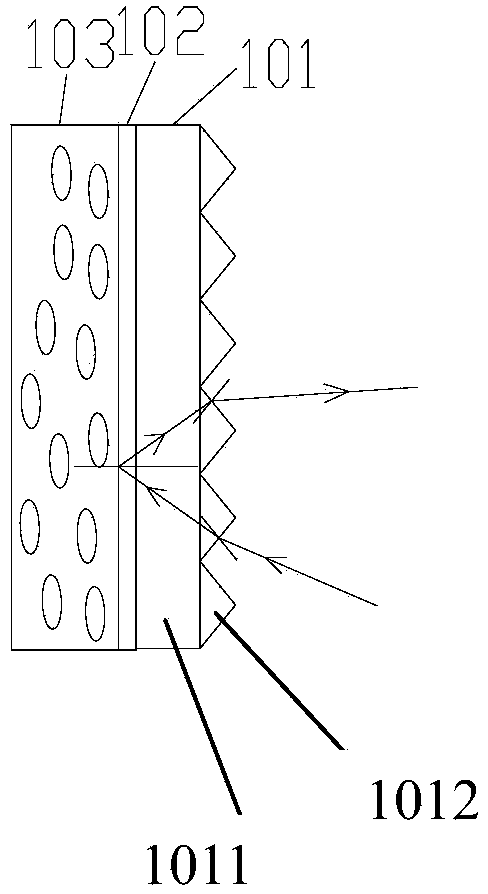

Embodiment 1

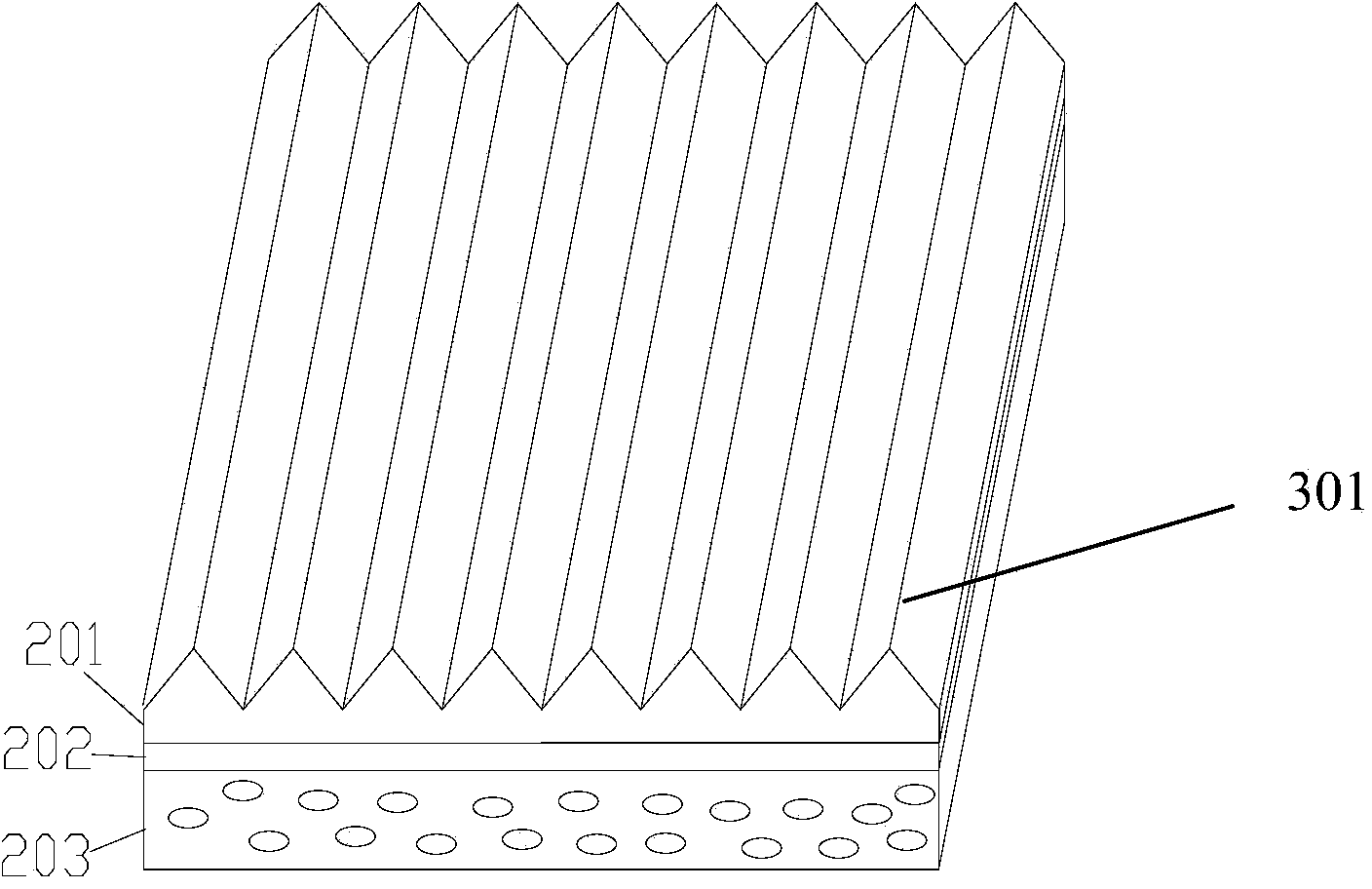

[0060] In the projection screen provided by the present invention, a white reflective film with a thickness of 188 μm is selected as the reflective layer, and the reflectivity of the white reflective film is 95.55%. Acrylic resin adhesive is coated on the surface of the reflective layer, and the thickness of the adhesive layer is 5 μm. The layer is combined with the reflective layer through the adhesive layer. The substrate of the refractive layer is PET material with a thickness of 150 μm. In the microprism structure: the height of the prism strip is 55 μm, and the side of the prism strip is an isosceles right angle triangle.

Embodiment 2

[0062] In the projection screen provided by the present invention, a white reflective film with a thickness of 200 μm is selected as the reflective layer, and the reflective rate of the white reflective film is 96.55%. Epoxy resin adhesive is coated on the surface of the reflective layer, and the thickness of the adhesive layer is 8 μm. The refractive layer is combined with the reflective layer through the adhesive layer. The base material of the refractive layer is PC material with a thickness of 100 μm. waist triangle.

Embodiment 3

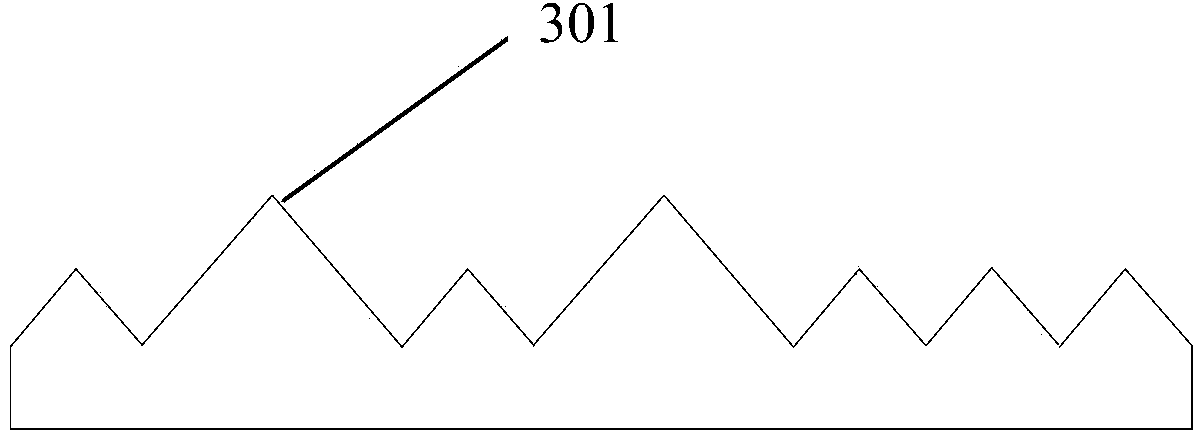

[0064] In the projection screen provided by the present invention, a silver reflective film with a thickness of 75 μm is selected as the reflective layer, and the reflectivity of the silver reflective film is 99%, and an acrylic resin adhesive is coated on the surface of the reflective layer, and the thickness of the adhesive layer is 25 μm. The layer is combined with the reflective layer through the adhesive layer. The base material of the refraction layer is PMMA material of 75 μm. In the microprism structure: the height of the prism strip is 55 μm, and the side of the prism strip is an isosceles right triangle with a right angle at the apex. The apex of the apex is an arc, and the radius R of the arc is 100 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Top angle | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com