Multi-atmosphere high-temperature dielectric temperature spectrum testing method

A technology of dielectric thermospectrum and testing method, which is applied in measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve problems such as large errors, achieve the goal of discarding wrong values, reducing system errors, and improving measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

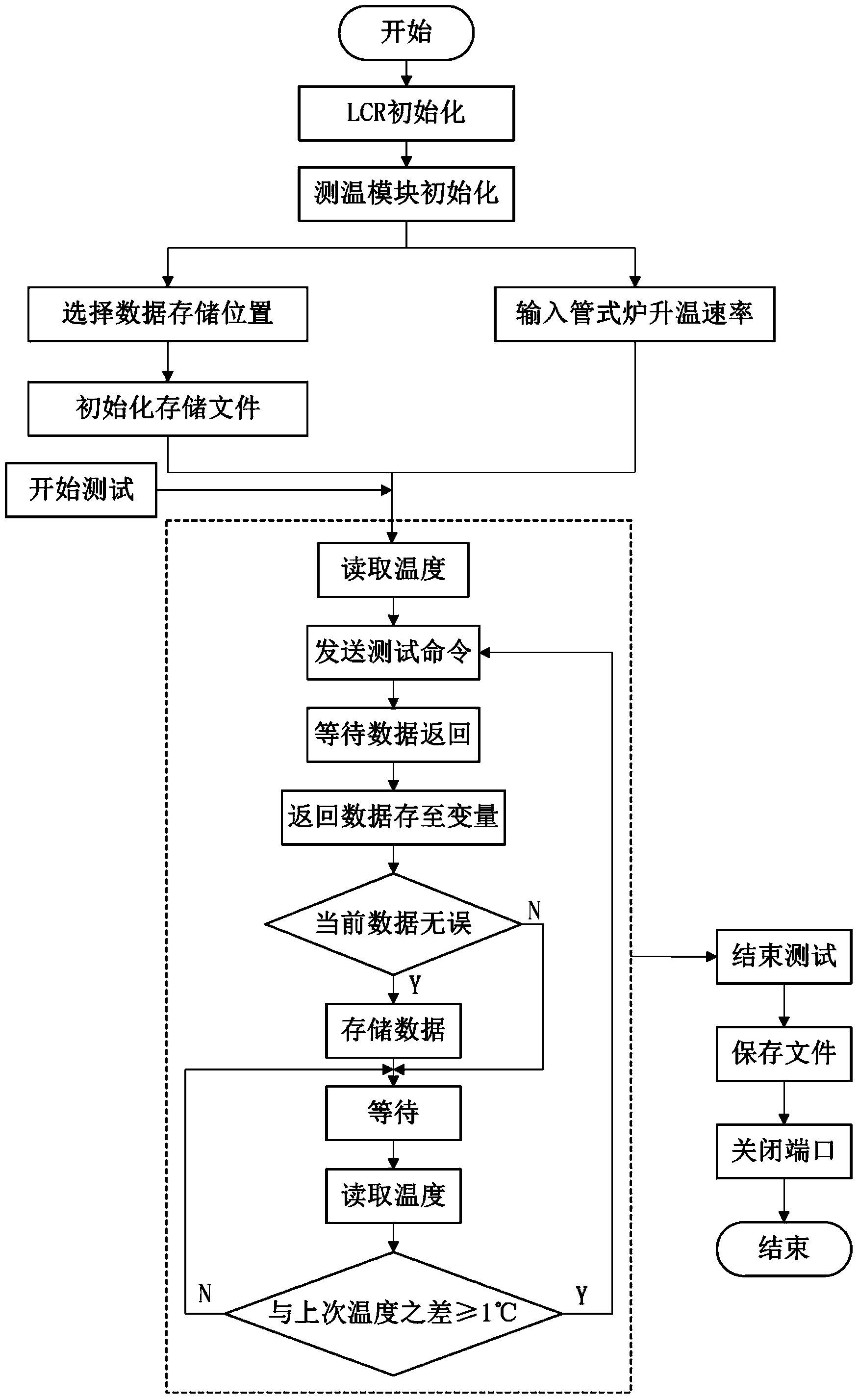

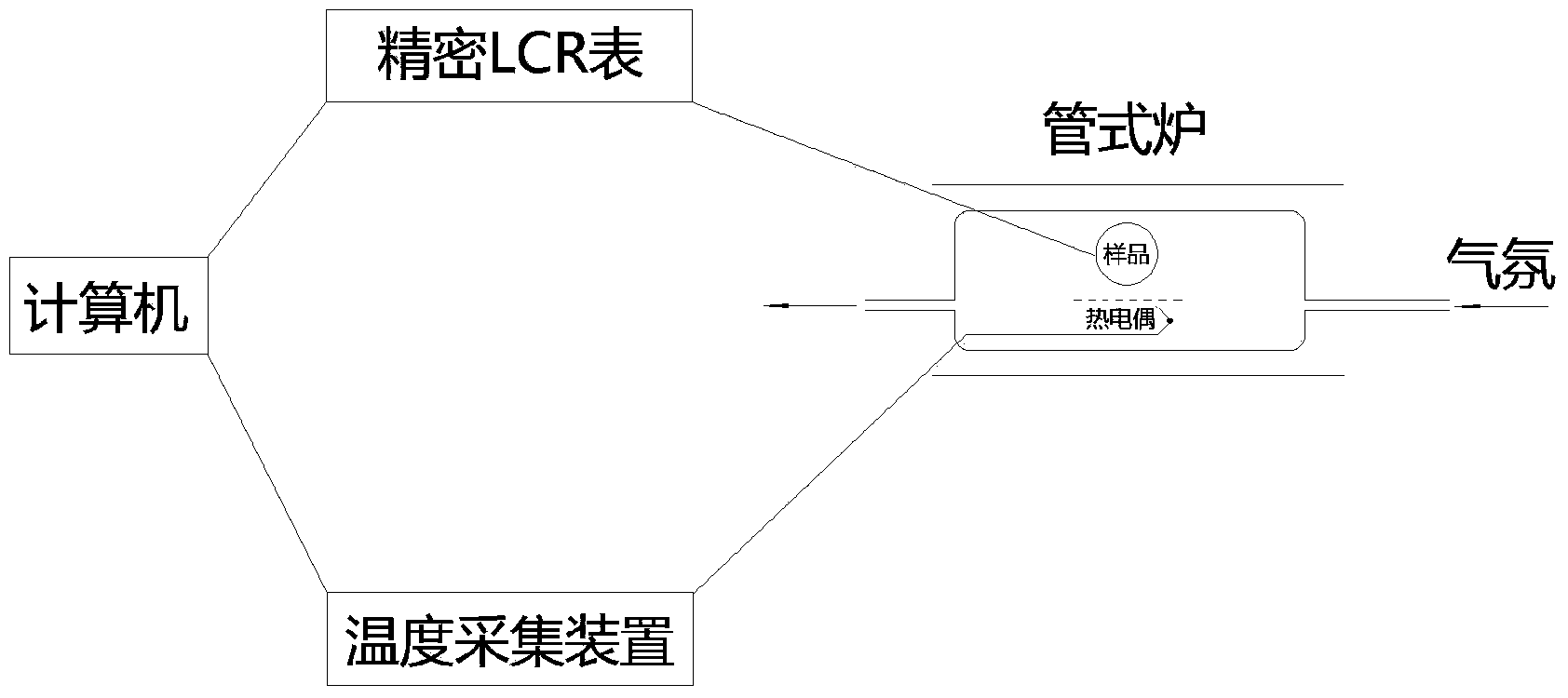

[0019] refer to Figure 1-2 . The specific steps of the multi-atmosphere high-temperature dielectric thermospectrum testing method of the present invention are as follows:

[0020] Establish hardware connections to the test system. The LCR meter uses Agilent's E4980Al precision LCR meter, the heating is transposed to Carbolite's MTF 10 / 25 / 130 tube furnace, and the temperature acquisition is transposed to Xiamen Yudian's AI-708 artificial intelligence temperature controller. The test sample is clamped in the platinum wire electrode, and the thermocouple is located adjacent to the sample to be tested. Platinum wire electrodes and thermocouple leads are connected to the outside world through reserved holes in the quartz tube. The four shielded wires of the precision LCR meter are connected to the other end of a platinum wire electrode in pairs to form a test loop. The quartz tube is placed in the tube furnace, and the atmospheric gas is passed into another reserved hole of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com