Deposited water defect damage detection method and system for inner part of composite material based on microwave excitation

A composite material and damage detection technology, which is applied in the direction of using microwave flaw detection, material analysis, and material analysis through optical means, can solve problems such as difficult detection of water droplets, infrared anomalies, and potential safety hazards, and achieve good detection results, clear relationships, and Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the accompanying drawings.

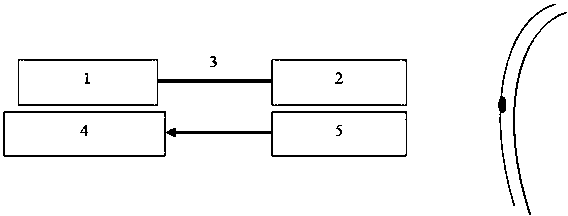

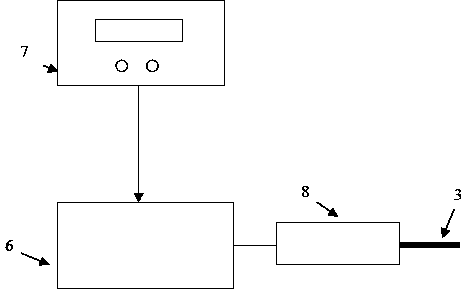

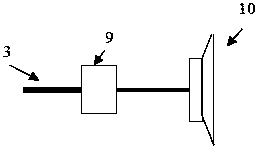

[0020] Such as figure 1 As shown, during the working process of the composite material component, the outer layer may be damaged under the action of external factors (such as complex stress, high and low temperature, impact load, scratching of hard objects, etc.), cracks, For defects such as small holes, moist air carries more water vapor from such defects into honeycomb, interlayer, sandwich and other structures. After changes in temperature and air pressure, the water vapor condenses into liquid water, which is difficult to discharge. After a long period of accumulation, water accumulation will have an important impact on the performance of composite materials and reduce the reliability of the structure. In particular, in important structures such as composite radomes, accumulated water in honeycombs and other places will seriously affect the propagation of electrom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com