Method for calibrating laser-damaged thresholds

A technology of laser damage threshold and calibration method, which is applied in the direction of testing optical properties, can solve the problems of limiting direct comparison and fluctuation of damage threshold measurement results, and achieves the effect of uniform particle size and spatial distribution, and good consistency of damage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

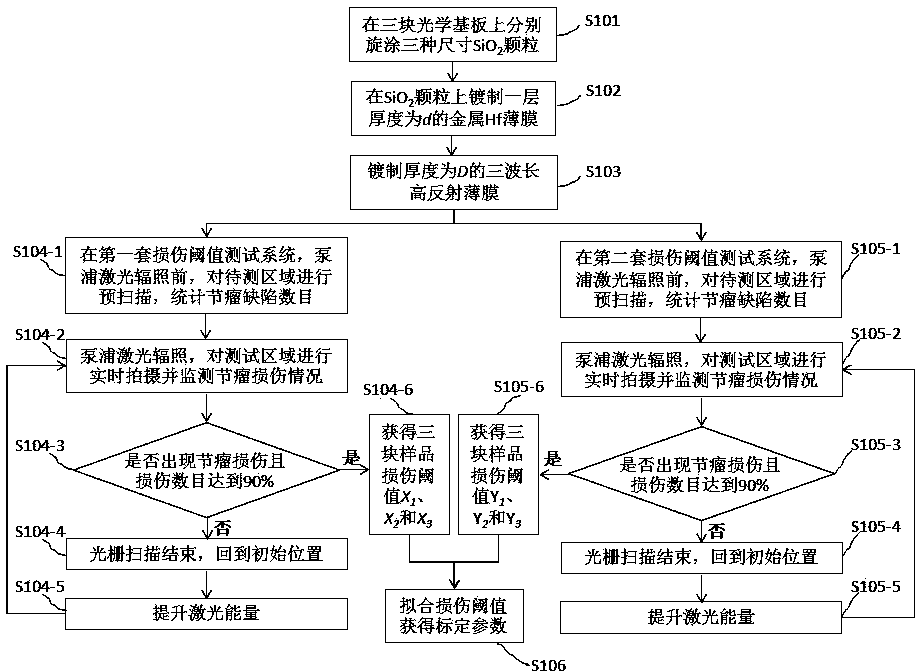

[0039]A method for calibrating laser damage threshold. The method takes artificial mixed nodular defects in high-reflection films as a reference, and statistically measures the damage threshold of 90% of nodular defects in a certain area, and uses this damage threshold as a benchmark for different The measurement results of the laser damage threshold test system are calibrated and calibrated.

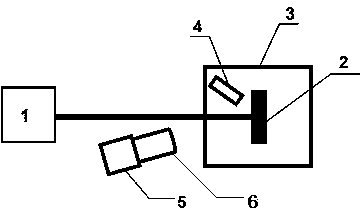

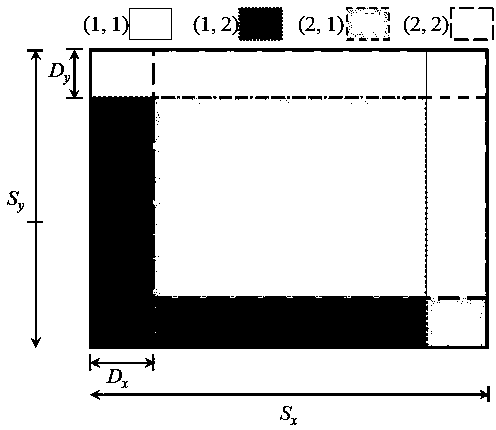

[0040] Test systems capable of damage threshold measurements of highly reflective laser thin films such as figure 1 As shown, the device for measuring the damage threshold includes a Nd:YAG pump laser 1 for emitting a pump laser with a working frequency of 10 Hz, an electric translation stage 3 with an external trigger function for driving the measured sample 2 to move, and realizing dark field illumination. The light source 4 and the damage monitoring component for real-time monitoring and acquiring images of the tested sample, the damage monitoring component includes an online microsc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com